Preparation method of bacitracin methylene disalicylate

A kind of methylene salicylic acid bacillus, methylene salicylic acid technology, applied in the direction of preparation method of peptide, bacitracin, chemical instrument and method, etc. and other problems, to achieve the effect of easy recycling, reducing degradation and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of methylenedisalicylic acid bacitracin, the steps are as follows:

[0041] Take 50kg of bacitracin premix, with bacitracin content of 20%, soak it in 8 times n-butanol for 4 hours; filter out the bacteria residue through two-in-one, collect the extract and heat it up to 65°C and concentrate it to 50L, take 4kg of methylene Dissolve salicylic acid in 4L of n-butanol, add it to the concentrated solution, and complex for 3 hours, use 15L of 0.4mol / L citric acid for three times of extraction; combine three times of acid water, adjust pH=7.6 with 1kg of caustic soda , to obtain the alkaline aqueous phase containing the target substance, and then dry it with a spray dryer to obtain 13.8kg of crude product.

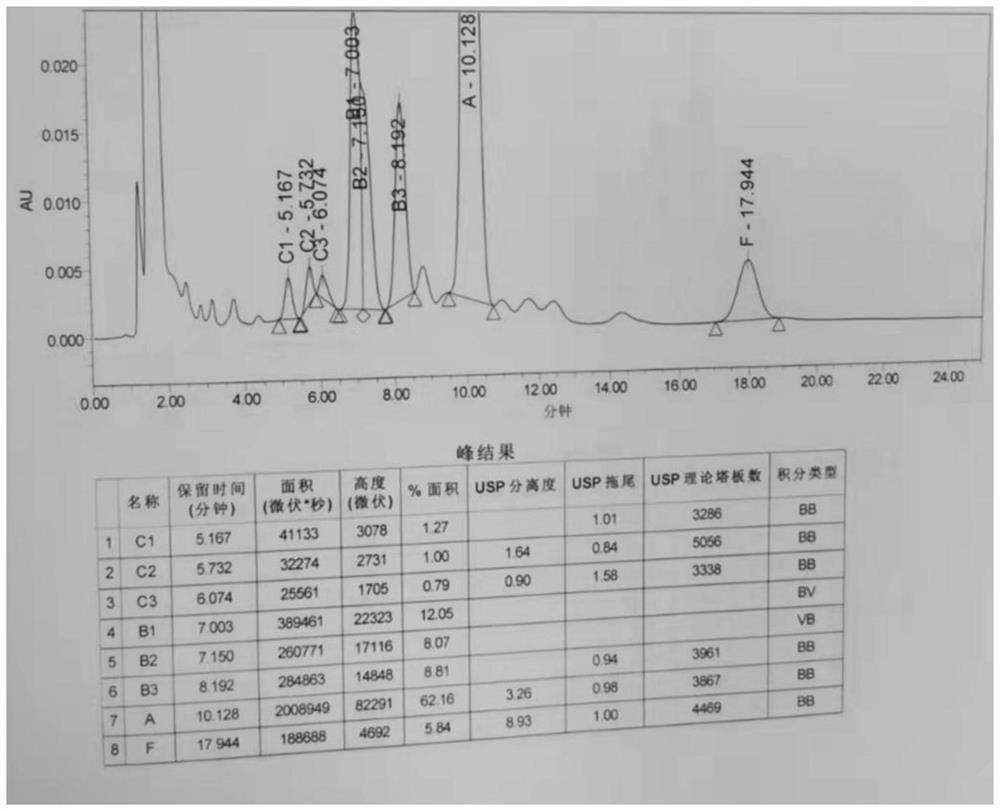

[0042] Add 1.11 kg of a mixture of sodium carbonate and sodium bicarbonate to the crude product and mix evenly. The mass ratio of sodium carbonate and sodium bicarbonate is 1:8; 14.91 kg of methylenedisalicylic acid bacitracin is obtained. The bacit...

Embodiment 2

[0044] A preparation method of methylenedisalicylic acid bacitracin, the steps are as follows:

[0045] Take 50kg of bacitracin premix, with bacitracin content of 20%, soak it in 6 times n-butanol for 4 hours, filter out the bacteria residue through two-in-one, collect the extract and heat it up to 65°C to concentrate to 37.5L. Get 3.8kg methylenedisalicylic acid and dissolve it with 3.6L n-butanol, join in the concentrated solution, complex for 2 hours, use 0.4mol / L citric acid 12L, carry out three extractions; combine three acidic waters, use Adjust the pH to 7.6 with 1 kg of caustic soda to obtain an alkaline aqueous phase containing the target substance, and then dry it with a spray dryer to obtain 13.3 kg of crude product.

[0046] Add 1.06 kg of a mixture of sodium carbonate and sodium bicarbonate to the crude product and mix evenly. The mass ratio of sodium carbonate and sodium bicarbonate is 1:8; 14.36 kg of methylenedisalicylic acid bacitracin finished product is obta...

Embodiment 3

[0048] A preparation method of methylenedisalicylic acid bacitracin, the steps are as follows:

[0049] Take 50kg of bacitracin premix, with bacitracin content of 20%, soak it in 6 times ethyl acetate for 4 hours, filter out the bacteria residue through two-in-one, collect the extract and heat it to 65°C to concentrate to 37.5L. Take 3.6kg of methylenedisalicylic acid and dissolve it with 3.6L of ethyl acetate, add it to the concentrated solution, and complex for 1-3 hours. Use 12L of 0.4mol / L citric acid for three times of extraction; combine the three times of acid water, adjust the pH to 7.8 with 1kg of caustic soda to obtain an alkaline aqueous phase containing the target substance, and then dry it with a spray dryer to obtain the crude product 12.6kg.

[0050] Add 1.01 kg of a mixture of sodium carbonate and sodium bicarbonate to the crude product and mix evenly. The mass ratio of sodium carbonate and sodium bicarbonate is 1:8; 13.61 kg of methylenedisalicylic acid bacit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com