All-solid-waste high-performance light material as well as preparation method and application thereof

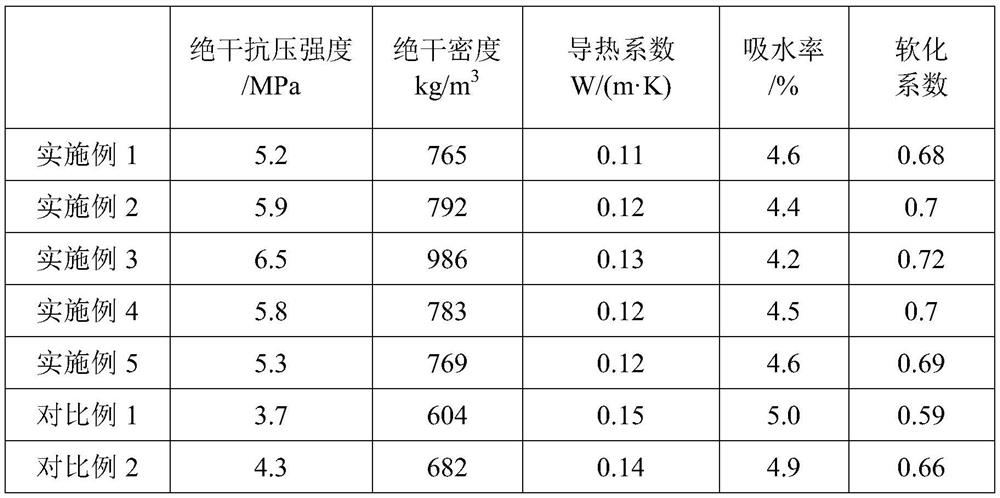

A light-weight material and high-performance technology, applied in the field of building materials, can solve problems such as poor water resistance, easy foaming, and cumbersome steps, and achieve improved water resistance and layering stability, excellent heat insulation performance, and preparation methods. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

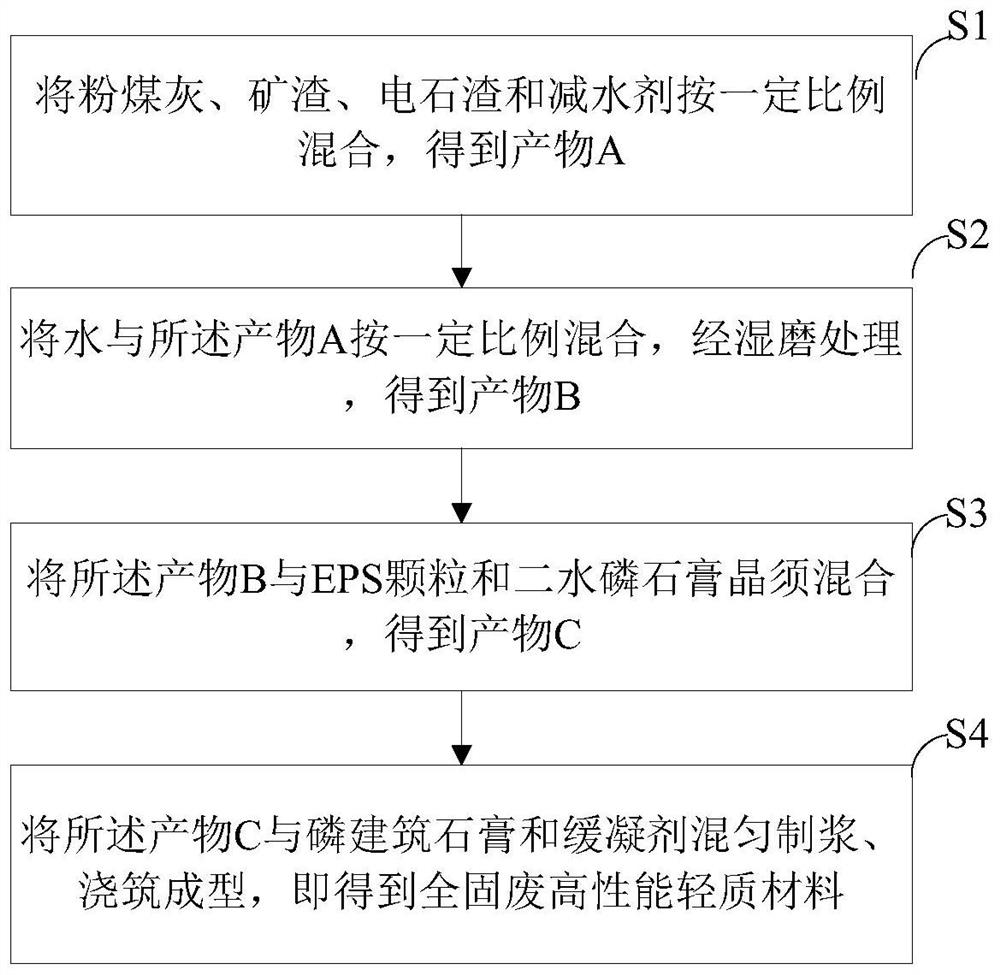

Method used

Image

Examples

Embodiment 1

[0038] A method for preparing all solid waste high-performance lightweight materials, comprising the following steps:

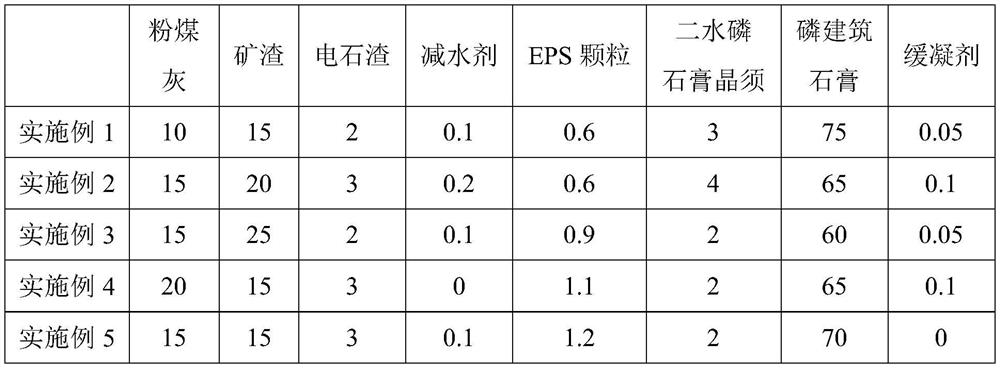

[0039] (1) According to the parts by weight shown in Table 1, take fly ash, slag, carbide slag and water reducer, and mix to obtain a mixture; wherein, 10 parts of fly ash are composed of 5 parts of Class I fly ash and Composed of 5 parts of Class II fly ash.

[0040] (2) Add water to the mixture in step (1) at a water-solid ratio (volume ratio) of 0.5, and wet mill to obtain a slurry. The milling speed of the wet mill is 330 rpm, and the time of the wet mill is 110 min.

[0041] (3) Put EPS particles, dihydrate phosphogypsum whiskers and the slurry prepared in step (2) in a mixer, and stir for 60 seconds to disperse the materials evenly; among them, 0.6 parts of EPS particles have a particle size of 1 to 3mmEPS and 3 ~5mmEPS is composed according to the volume ratio of 0.2:1.

[0042] (4) Add the product of step (3), phosphorus building gypsum and retarder...

Embodiment 2

[0044] A method for preparing all solid waste high-performance lightweight materials, comprising the following steps:

[0045] (1) According to the parts by weight shown in Table 1, take fly ash, slag, carbide slag and water reducer, and mix to obtain a mixture; wherein, 15 parts of fly ash are composed of 5 parts of Class I fly ash and Composed of 10 parts of Class II fly ash.

[0046] (2) Add water to the mixture in step (1) at a water-solid ratio (volume ratio) of 0.6, and wet-grind to obtain a slurry. The grinding speed of the wet-mill is 380 rpm, and the time of the wet-mill is 100 minutes.

[0047] (3) Put EPS particles, dihydrate phosphogypsum whiskers and the slurry prepared in step (2) in a mixer, and stir for 55 seconds to disperse the materials evenly; among them, 0.6 parts of EPS particles have a particle size of 1 to 3mmEPS and 3 ~5mmEPS is composed according to the volume ratio of 0.3:1.

[0048] (4) Add the product of step (3), phosphorus building gypsum and r...

Embodiment 3

[0050] A method for preparing all solid waste high-performance lightweight materials, comprising the following steps:

[0051] (1) According to the parts by weight shown in Table 1, take fly ash, slag, carbide slag and water reducer, and mix to obtain a mixture; wherein, 15 parts of fly ash are composed of 10 parts of class I fly ash and Composed of 5 parts of Class II fly ash.

[0052] (2) Add water to the mixture in step (1) at a water-solid ratio (volume ratio) of 0.7, and wet mill to obtain a slurry. The milling speed of the wet mill is 400 rpm, and the time of the wet mill is 90 minutes.

[0053] (3) Put the EPS particles, dihydrate phosphogypsum whiskers and the slurry prepared in step (2) in a mixer, and stir for 50 seconds to disperse the materials evenly; among them, 0.6 parts of EPS particles have a particle size of 1 to 3mmEPS and 3 ~5mmEPS is composed according to the volume ratio of 0.35:1.

[0054] (4) Add the product of step (3), phosphorus building gypsum and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Dry compressive strength | aaaaa | aaaaa |

| Absolute dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com