MWW molecular sieve, preparation method thereof and application of alkaloid in preparation of MWW molecular sieve

A technology of molecular sieves and alkaloids, applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as industrial application restrictions, environmental health hazards, etc., achieve low cost, inhibit crystal transformation, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] The present invention provides a kind of preparation method of MCM-56 molecular sieve, wherein, the method comprises:

[0086] Silica gel (3g, pore size 2.5-4nm), NaAlO 2 , NaOH, (CH 3 ) 3 N + CH 2 CH 2 OH and H 2 O is 1SiO in molar ratio 2 :1 / 30Al 2 o 3 :0.1OH - :20H 2 O:0.1 template ((CH 3 ) 3 N + CH 2 CH 2 OH) mixed to form a mixture;

[0087] Add ITQ-1 molecular sieve active crystal seed to the mixture, obtain mixed glue; Wherein, the mass ratio of ITQ-1 molecular sieve active crystal seed and silica gel is, ITQ-1 molecular sieve active crystal seed:SiO 2 =0.05;

[0088] The mixed gum was hydrothermally crystallized at 150° C. for 48 hours, and the product obtained by hydrothermal crystallization was centrifuged, washed and dried to obtain MCM-56 molecular sieve.

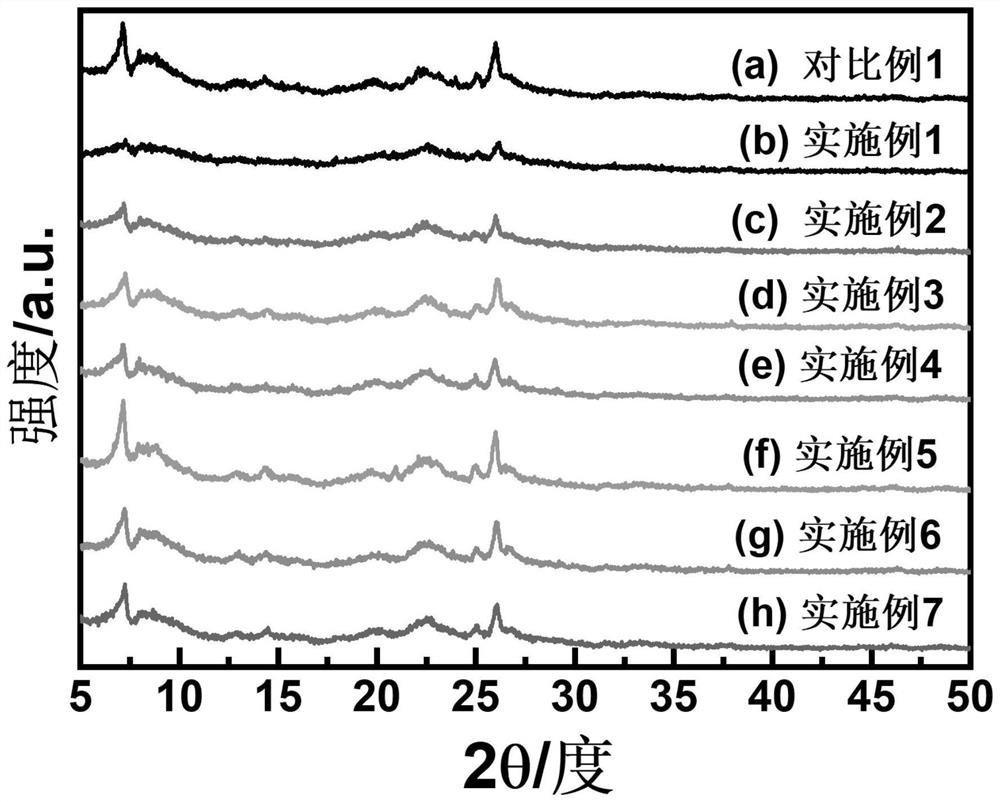

[0089] Obtain the XRD figure of the MCM-56 molecular sieve prepared by the present embodiment, the result is as follows figure 1 As shown in the b spectrum in figure 1 It can be seen f...

Embodiment 2

[0092] The present invention provides a kind of preparation method of MCM-56 molecular sieve, wherein, the method comprises:

[0093] Coarse-porous silica gel (3g, pore size 5-10nm), aluminum chloride, KOH, (CH 3 ) 3 N + CH 2 COO - and H 2 O is 1SiO in molar ratio 2 :0.04Al 2 o 3 :0.12OH - :25H 2 O:0.15 template ((CH 3 ) 3 N + CH 2 COO - ) mixed to form a mixture;

[0094] Add MCM-22 molecular sieve active crystal seed to the mixture to obtain mixed glue; wherein, the mass ratio of MCM-22 molecular sieve active crystal seed to silica gel is, MCM-22 molecular sieve active crystal seed: SiO 2 =0.02;

[0095] The mixed gum was hydrothermally crystallized at 150° C. for 72 hours, and the product obtained by hydrothermal crystallization was centrifuged, washed and dried to obtain MCM-56 molecular sieve.

[0096] Obtain the XRD figure of the MCM-56 molecular sieve prepared by the present embodiment, the result is as follows figure 1 As shown in the c spectrum in f...

Embodiment 3

[0099] The present invention provides a kind of preparation method of MCM-56 molecular sieve, wherein, the method comprises:

[0100] Sodium silicate (6.1g), aluminum nitrate, KOH, CH 3 COOCH 2 CH 2 N(CH 3 ) 3 and H 2 O is 1SiO in molar ratio 2 :0.05Al 2 o 3 :0.13OH - :20H 2 O:0.18 template (CH 3 COOCH 2 CH 2 N(CH 3 ) 3 ) mixed to form a mixture;

[0101] Add SMC-1 crystal seed (prepared by the synthetic example of above-mentioned seed crystal SCM-1) in the mixture, obtain mixed glue; Wherein, the mass ratio of SMC-1 crystal seed and silica gel is, SMC-1 crystal seed: SiO 2 =0.02;

[0102] The mixed gum was hydrothermally crystallized at 150° C. for 96 hours, and the product obtained by hydrothermal crystallization was centrifuged, washed and dried to obtain MCM-56 molecular sieve.

[0103] Obtain the XRD pattern of the MCM-56 molecular sieve prepared by the present embodiment, the results are as follows figure 1 As shown in the d diagram in figure 1It can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com