Preparation method of high-finish polytetrafluoroethylene tube

A technology of polytetrafluoroethylene pipe and polytetrafluoroethylene, which is applied in the direction of coating, can solve the problem of low finish, achieve high surface finish, meet strict requirements, and reduce surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

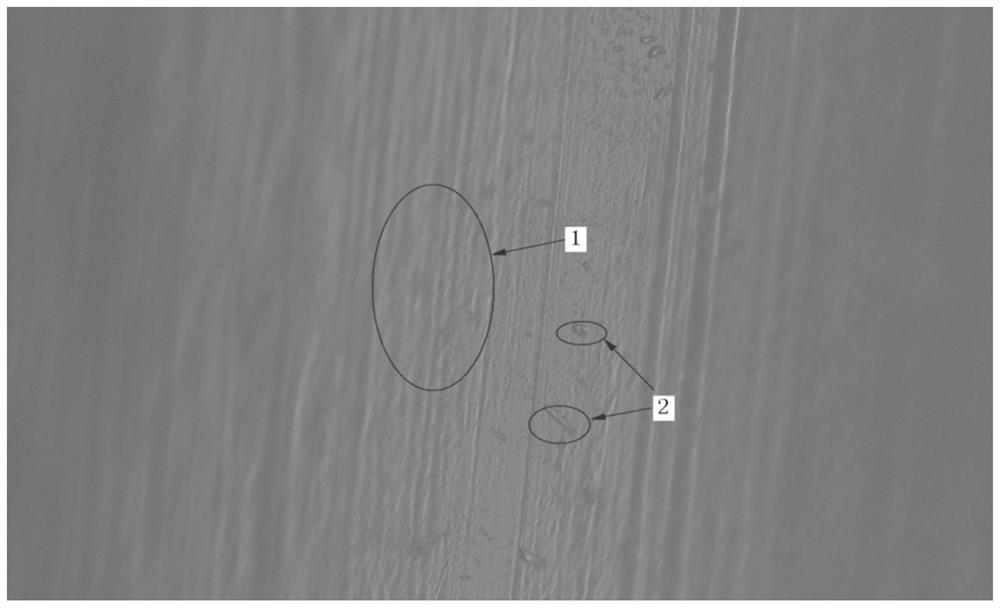

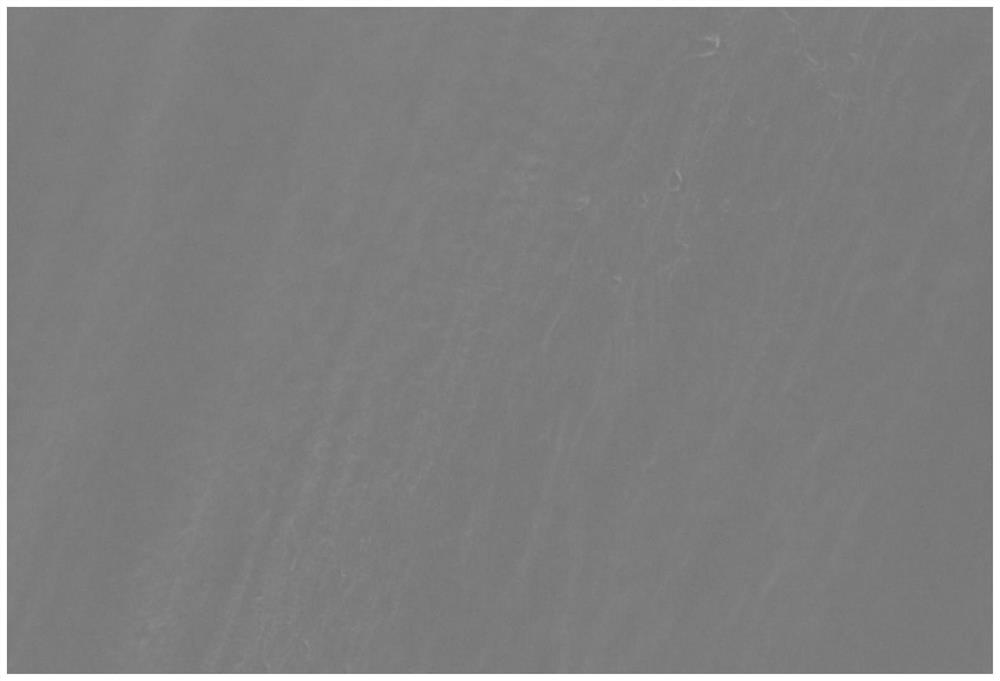

Image

Examples

Embodiment 1

[0029] (1) Mixing: Select polytetrafluoroethylene dispersion resin DF2041 with SSG of 2.186 and extrusion pressure of 51.3MPa at a compression ratio of 1600:1. First, DF2041 is screened with an 8-mesh screen, and then added with a resin weight of 20 % additives, mixed evenly;

[0030] (2) Ripening: put the mixed material at 35°C for 18 hours;

[0031] (3) Preforming: pre-press molding the matured material, the molding pressure is 2.5MPa, and the pressure is kept for 25min;

[0032] (4) Extrusion: Put the preformed blank into the extruder, control the temperature of the material cavity to 40°C and the temperature of the head to 66°C, and control the extrusion speed to 3.0m / min to obtain a raw tube of 4.0-5.0mm;

[0033] (5) Drying and sintering: the extruded pipe passes through the heating furnace, and the temperature from the inlet of the drying section of the heating furnace to the outlet of the sintering section gradually increases. agent, the temperature of the sintering ...

Embodiment 2

[0038] (1) Mixing: Select polytetrafluoroethylene dispersion resin DF2041 with SSG of 2.180 and extrusion pressure of 56.6MPa at a compression ratio of 1600:1. First, DF2041 is screened with an 8-mesh screen, and then the resin weight 18 % additives, mixed evenly;

[0039] (2) Curing: put the mixed material at 30°C for 22 hours;

[0040] (3) Preforming: pre-press molding the matured material, the molding pressure is 2.0MPa, and the pressure is kept for 30min;

[0041] (4) Extrusion: Put the preformed blank into the extruder, control the temperature of the material cavity to 40°C and the temperature of the head to 60°C, and control the extrusion speed to 1.5m / min to obtain a raw tube of 8.5-10.5mm;

[0042] (5) Drying and sintering: the extruded pipe passes through the heating furnace, and the temperature from the inlet of the drying section of the heating furnace to the outlet of the sintering section gradually increases. agent, the temperature of the sintering section is 36...

Embodiment 3

[0047] (1) Mixing: Select polytetrafluoroethylene dispersion resin DF-2048 with SSG of 2.171 and extrusion pressure of 55.7MPa at a compression ratio of 1600:1. First, sieve DF-2048 with an 8-mesh screen, and then Add 20% additives by resin weight and mix well;

[0048] (2) Ripening: put the mixed material at 40°C for 12 hours;

[0049] (3) Preforming: pre-press molding the matured material, the molding pressure is 2.3MPa, and the pressure is kept for 25min;

[0050] (4) Extrusion: Put the preformed blank into the extruder, control the temperature of the material cavity to 40°C and the temperature of the head to 70°C, and control the extrusion speed to 2.8m / min to obtain a raw tube of 4.0-5.0mm;

[0051] (5) Drying and sintering: the extruded pipe passes through the heating furnace, and the temperature from the inlet of the drying section of the heating furnace to the outlet of the sintering section gradually increases. agent, the temperature of the sintering section is 360-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com