Protective film fixed-distance section cutting device for highway bridge engineering

A technology for road bridges and protective films, applied in metal processing, etc., can solve problems such as uneven cutting, uncontrollable cutting speed, and inability to ensure smooth incision, so as to reduce the contact area, increase the pressure, and reduce the probability of damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

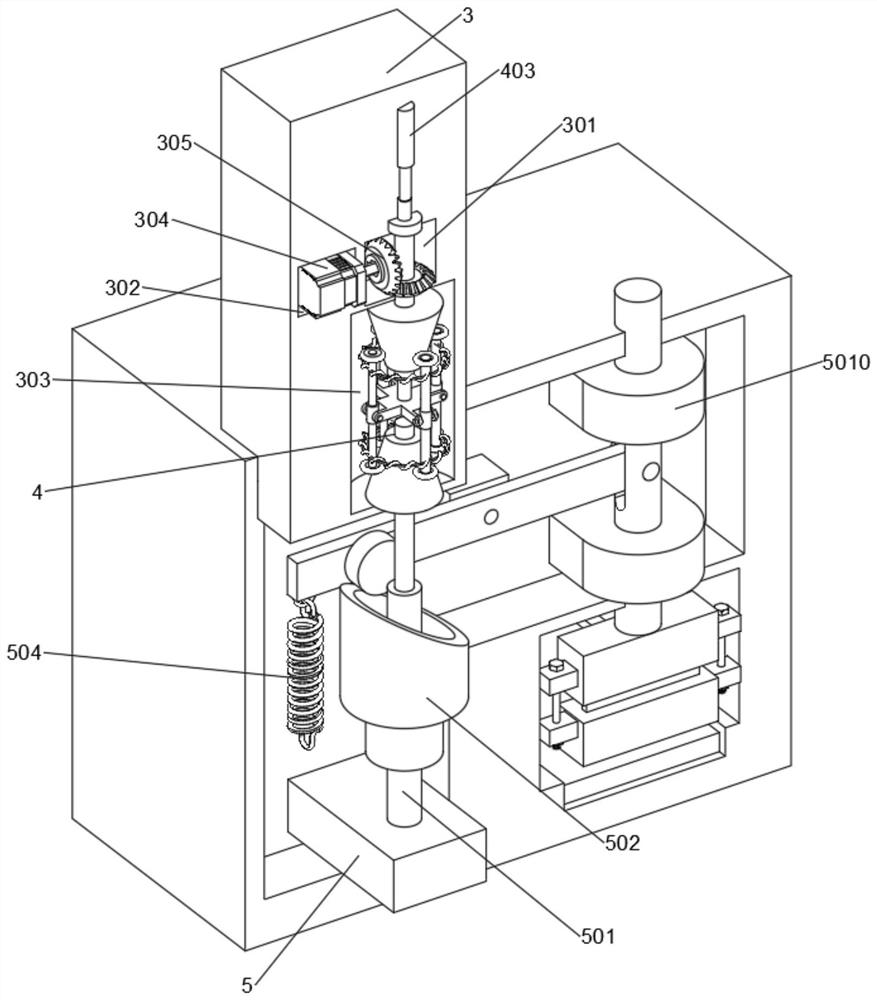

[0027] see Figure 1-5 , the present invention provides a kind of technical scheme:

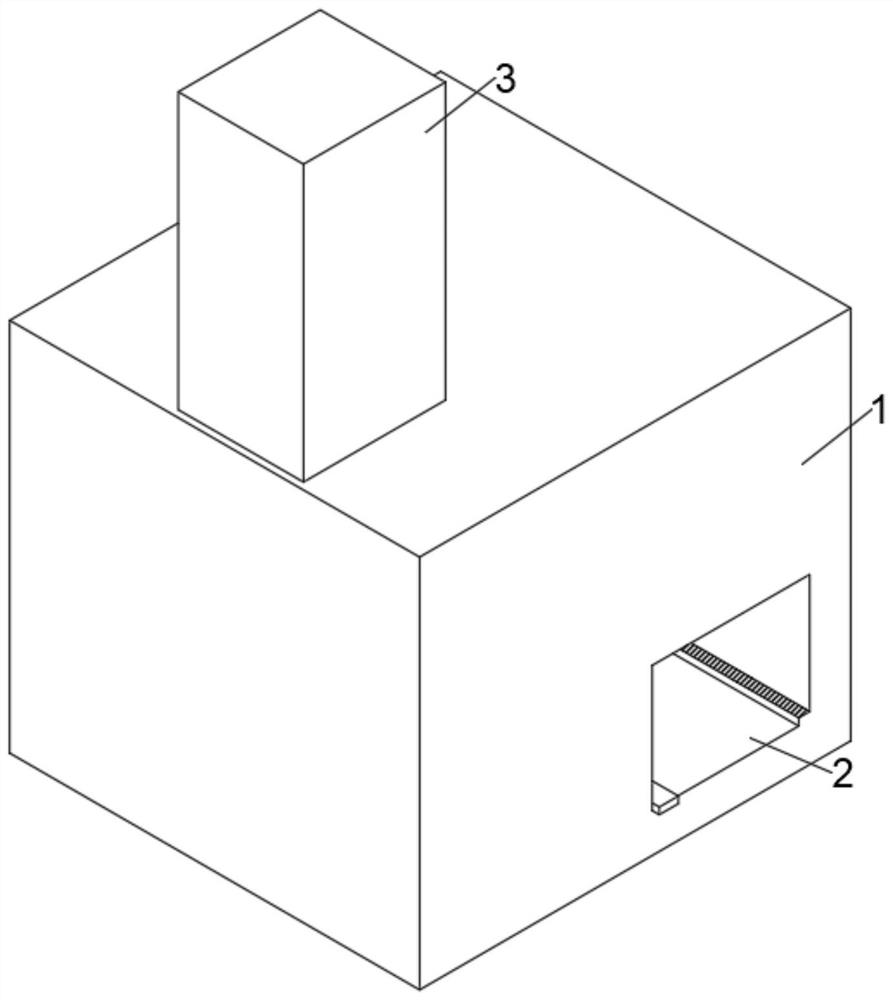

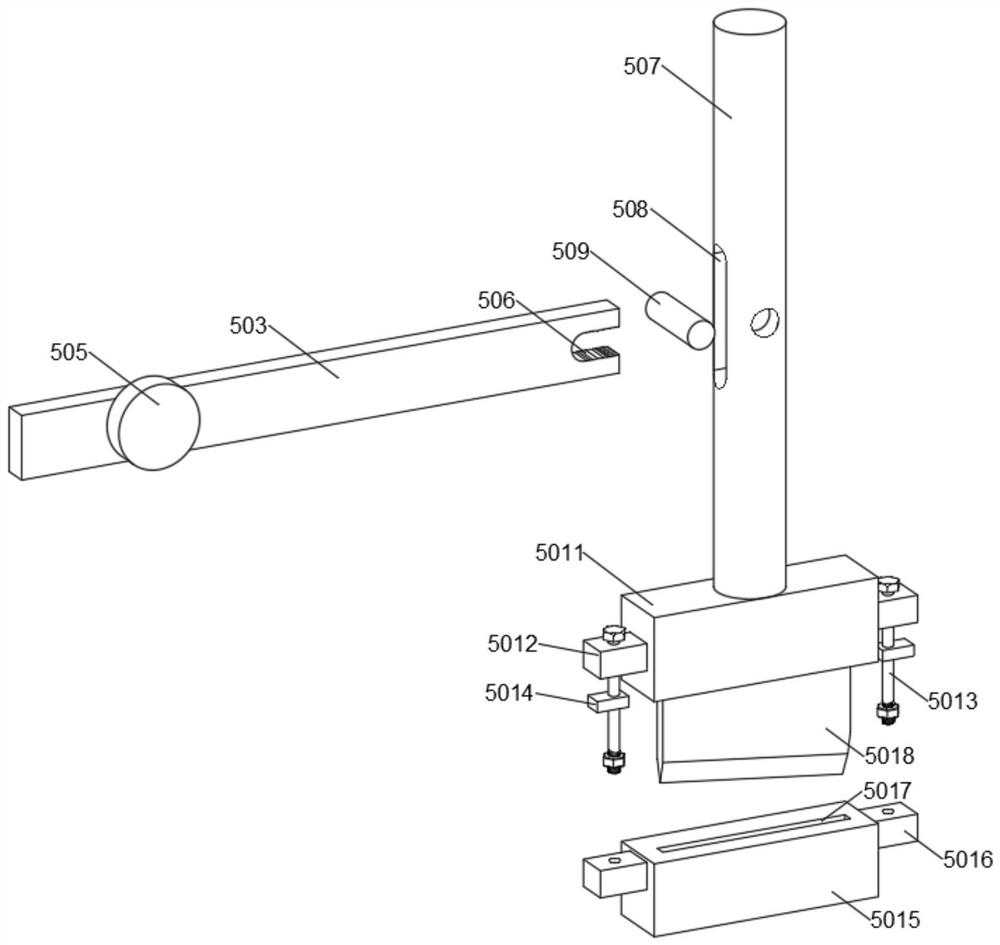

[0028] A protective film fixed-distance cutting device for highway and bridge engineering, comprising a cutting box 1, a working path 2 set on the lower side of the cutting box, a scale line is provided on one side of the bottom surface of the working path 2, and embedded in the cutting box 1 On the surface of the speed change protection box 3, a square chamber 301 is opened on one side of the middle part of the speed change protection box 3, an organic cavity 302 is opened on the other side of the middle part of the speed change protection box 3, and a speed change chamber 303 is opened on the lower side of the speed change protection box 3; The synchronous clamping and cutting mechanism arranged inside the cutting box 1; the speed change adjustment mechanism arranged inside the speed change chamber.

[0029] Further, a motor 304 is provided inside the machine cavity 302 , a hollow shaft 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com