A small tensile electrical connector

An electrical connector and tensile technology, which is applied in the direction of connection, parts of connecting devices, devices for reducing the stress at the connection of wires, etc., can solve problems such as poor tensile performance, and achieve the effect of solving poor tensile performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

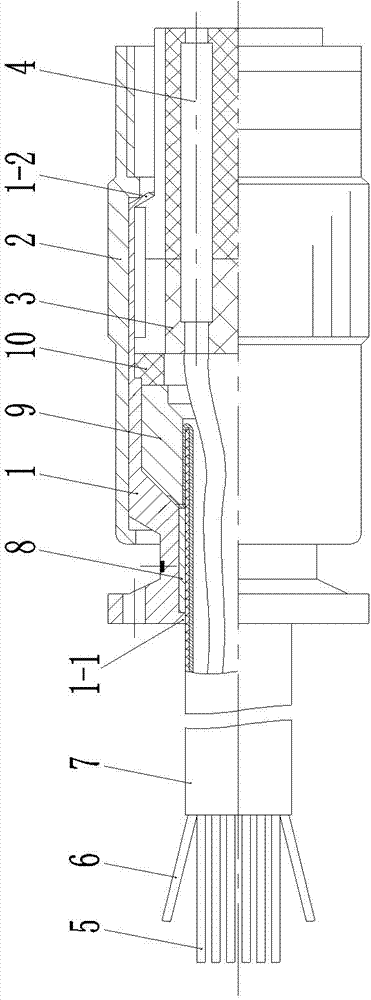

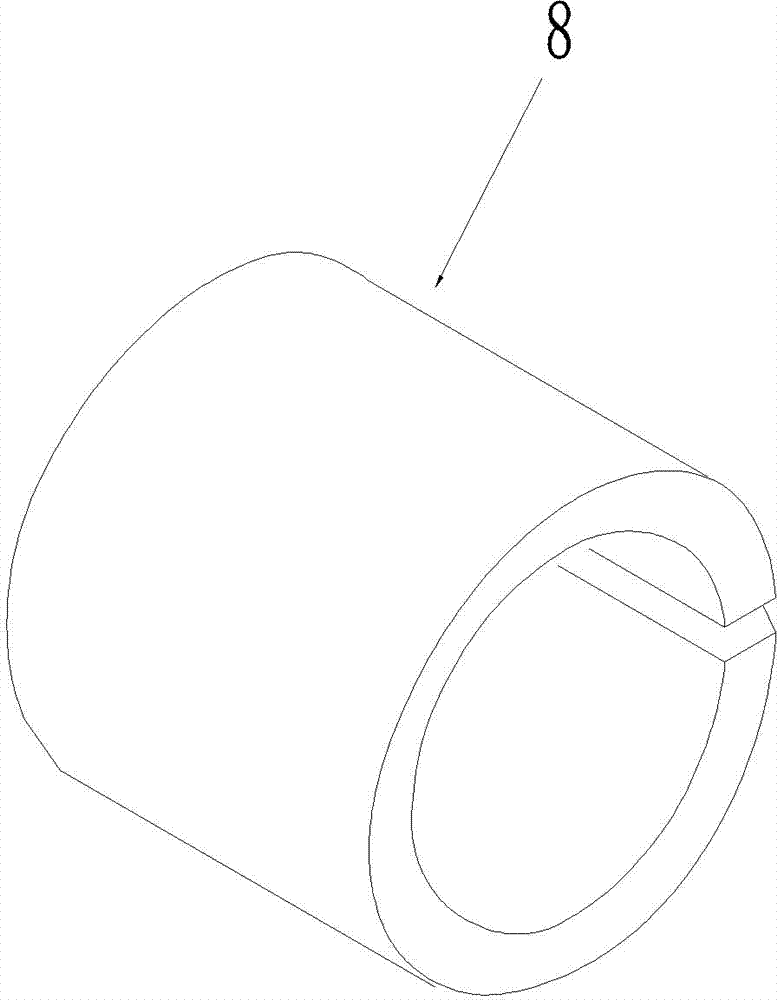

[0015] Embodiment 1 of the small tensile electrical connector of the present invention, such as Figure 1-3 As shown, there is a cylindrical metal shell 1 as a whole, and the metal shell 1 can play a certain shielding effect; the metal shell 1 is provided with a connecting nut 2 along the axial direction, and the connecting nut 2 is connected to the The metal shell 1 is rotated and fitted, and the metal shell 1 is provided with a contact module. The contact module is composed of an insulator 3 and a contact 4 assembled on the insulator 3; the tail end of the metal shell 1 is provided with a tail cable. The cable is composed of a wire 5, a shielded wire 6 and an outer sheath 7. The wire 5 of the tail cable is connected to the corresponding contact piece, and its front end extends into the metal shell 1. The part of the tail cable located in the metal shell 1 is covered with a fixed 8, the fixed sleeve 8 adopts a C-shaped metal sleeve, and the fixed sleeve 8 is compressed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com