Fried puffed biscuit containing shrimp shell powder or chitin additive and application

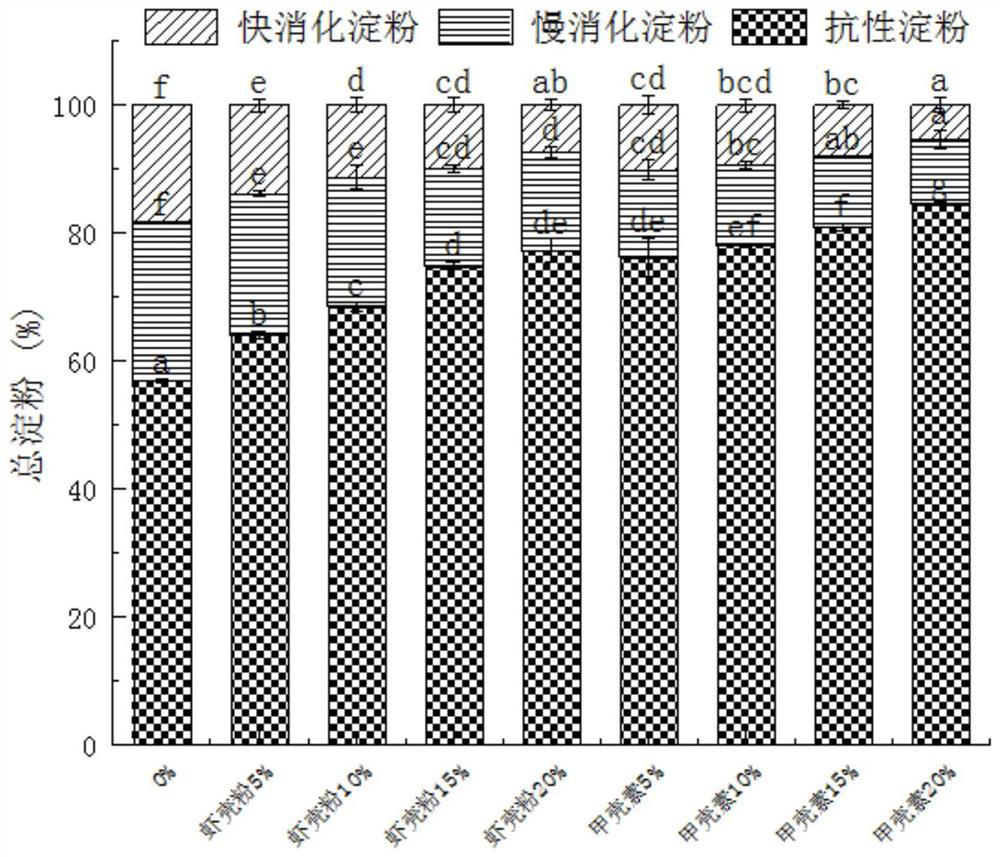

A technology of frying puffed and puffed biscuits, which is applied in the food field to achieve the effect of reducing the percentage, increasing the hardness, and increasing the content of resistant starch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The fried puffed biscuits containing shrimp shell powder additives provided in this example are mainly made of the following raw materials: mixed flour of wheat flour and glutinous rice flour, shrimp shell powder, yeast powder, salt, soda powder, eggs and water, wherein wheat flour and glutinous rice The mass ratio of the powder is 11:3, and based on the total mass of the mixed powder of wheat flour and glutinous rice flour, the added amount of the shrimp shell powder or chitin additive is 8%.

[0042] The main components of fried biscuits are wheat flour and glutinous rice flour, which are obtained by frying with rapeseed oil or soybean oil as the medium. The ratio is stirred and mixed evenly, then shrimp shell powder (SS) is added to the wheat flour-glutinous rice flour mixed flour with 8% (based on the total mass of wheat flour and glutinous rice flour) and stirred evenly, and 0.7% yeast powder, 3% salt, 3% soda powder, 36% eggs and 10% water (based on the total mass...

Embodiment 2

[0044] The difference from Example 1 is that the additive is chitin.

Embodiment 3

[0046] The fried puffed biscuits containing shrimp shell powder additives provided in this example are mainly made of the following raw materials: mixed flour of wheat flour and glutinous rice flour, shrimp shell powder, yeast powder, salt, soda powder, eggs and water, wherein wheat flour and glutinous rice The mass ratio of the flour is 11:3, and the added amount of the shrimp shell powder or chitin additive is 10% based on the total mass of the mixed flour of wheat flour and glutinous rice flour.

[0047] The preparation method refers to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com