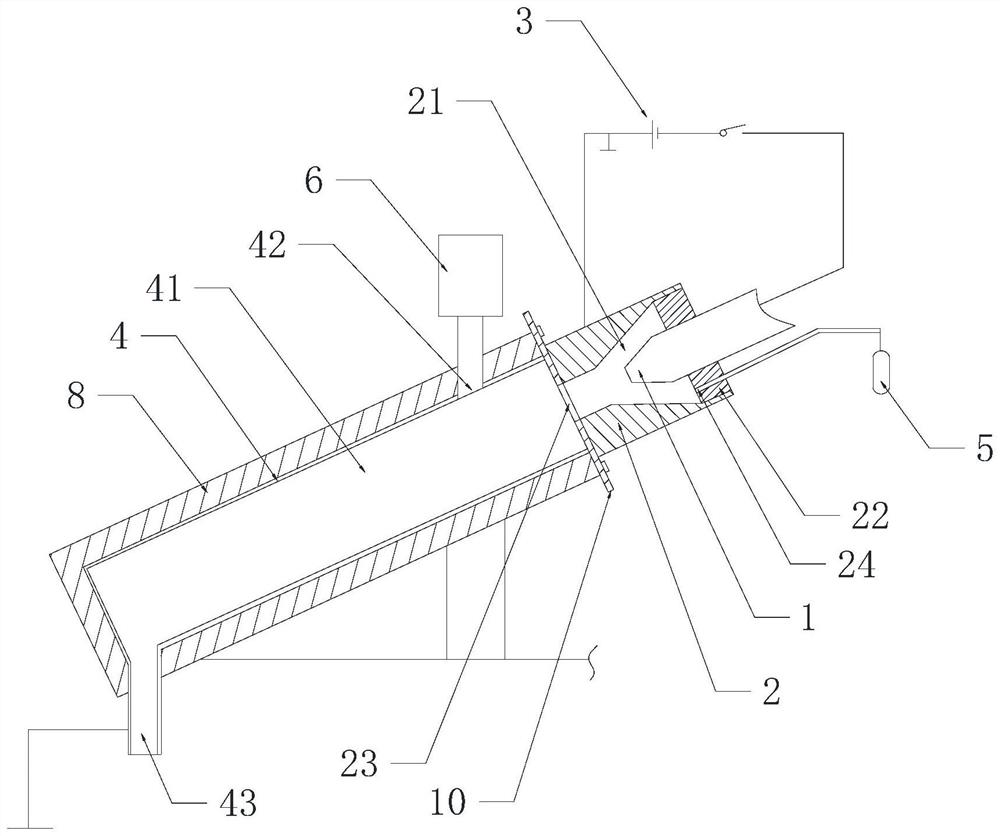

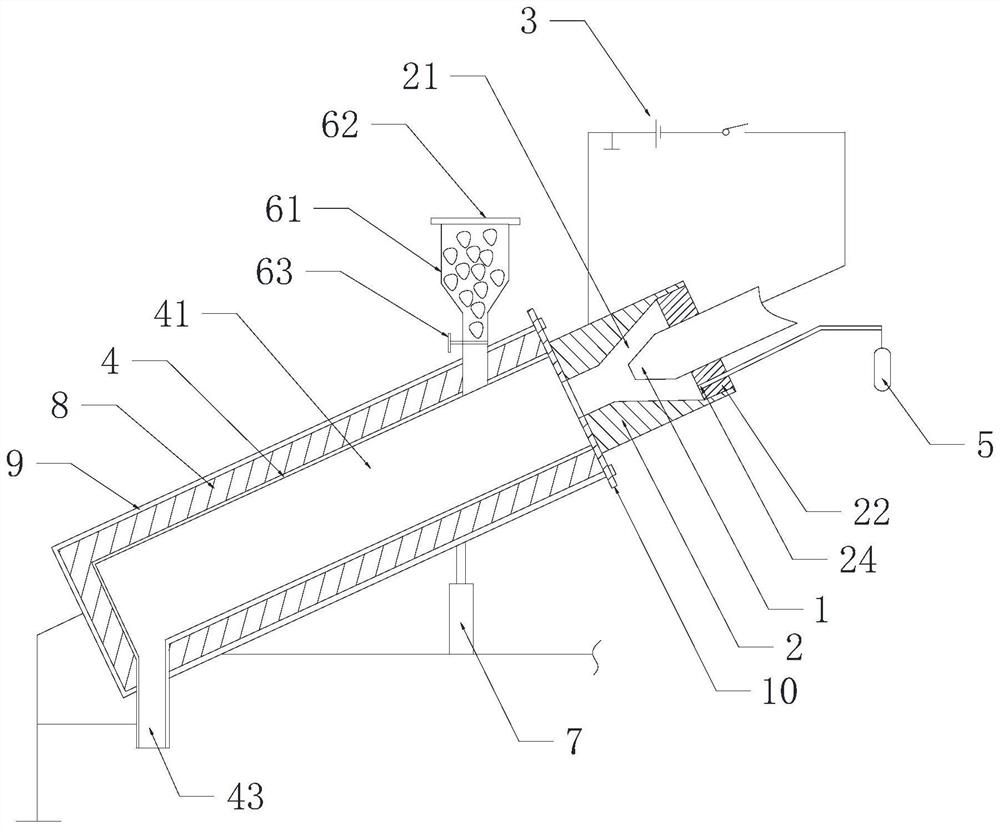

Plasma torch system for anode chamber incineration

A plasma torch and plasma technology, applied in the field of waste treatment, can solve the problems of limited beam expansion space, a large amount of nitrogen oxides, and low thermal efficiency of incineration, so as to reduce the difficulty of water cooling, avoid nitrogen oxides, and increase the expansion space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to clearly describe the technical characteristics of the present scheme, the present invention will be described in detail by those skilled in the following drawings. Many specific details are set forth in the following description to fully understand the present application, but the present application can also employ other different from those described herein, and therefore, the protection range of the present application is not subject to the specifically disclosed below. The limitations of embodiments.

[0039] In the description of this specification, the description of the reference terms "one embodiment", "some embodiments", "example", "specific example", or "some example", etc., meant to conjunction with the specific characteristics described in connection with this embodiment. , Structures, materials or features are included in at least one embodiment or example of the present application. In the present specification, the schematic representation of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com