Preparation method of low-anisotropy high-plasticity magnesium alloy

An anisotropic, magnesium alloy technology, applied in the field of magnesium alloy material manufacturing, can solve the problems of high technical difficulty, complex process, multi-directional forging, etc., and achieve the effect of simple processing technology operation, simple equipment, and weakening anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Select a magnesium alloy ingot Mg-1%wtZn-0.3%wtCe ternary alloy, homogenize it at 480° C. for 18 hours, and air-cool to room temperature to obtain a magnesium alloy billet.

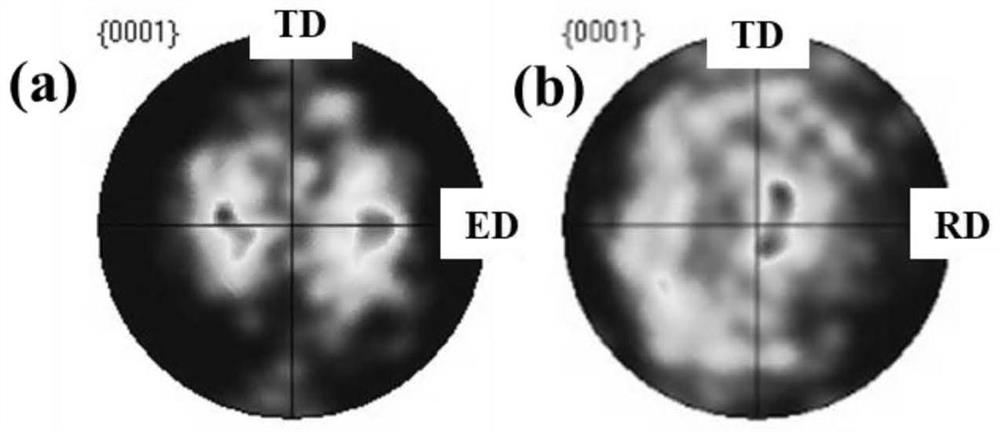

[0029] 2) Preheat the homogenized magnesium alloy billet to 450-460°C, then put it into the extrusion barrel and carry out hot extrusion in the extrusion machine, the extrusion temperature is 450°C, the extrusion ratio is 30:1, and the extrusion The blank after pressing is 56mm wide and 3mm thick.

[0030] 3) The extruded billet is cold-rolled one pass along the extrusion direction, with a reduction of 5% per pass, and then annealed. The annealing temperature is 350°C and the annealing time is 1h, which is the low anisotropy and high plastic magnesium alloy.

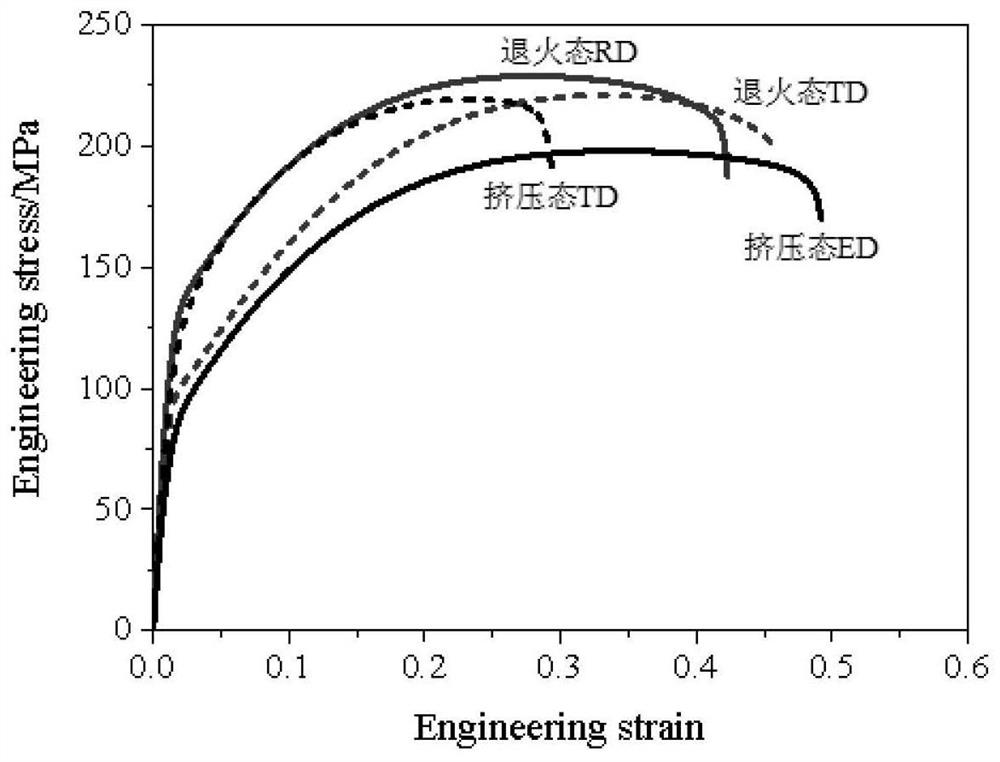

[0031] Its ultimate tensile strength at room temperature along RD (rolling direction) of the magnesium alloy obtained in the present embodiment is 239MPa, and the elongation after stretching is 32.6%, and the ultimate tensile strength at ...

Embodiment 2

[0033] 1) Select a magnesium alloy ingot Mg-1%wtZn-0.3%wtCe ternary alloy, homogenize it at 480° C. for 18 hours, and air-cool to room temperature to obtain a magnesium alloy billet.

[0034] 2) Preheat the homogenized magnesium alloy billet to 450-460°C, then put it into the extrusion barrel and perform hot extrusion in the extrusion machine, the extrusion temperature is 450°C, the extrusion ratio is 30:1, and the extrusion The blank after pressing is 56mm wide and 3mm thick.

[0035] 3) The extruded billet is cold-rolled one pass along the extrusion direction, with a reduction of 8% per pass, and then annealed. The annealing temperature is 350°C and the annealing time is 1h, which is the low anisotropy and high plastic magnesium alloy.

[0036] Its ultimate tensile strength at room temperature along RD (rolling direction) of the magnesium alloy gained in the present embodiment is 233MPa, and the elongation after stretching is 42.2%, and the ultimate tensile strength at room...

Embodiment 3

[0038] 1) Select a magnesium alloy ingot Mg-1%wtZn-0.3%wtCe ternary alloy, homogenize it at 480° C. for 18 hours, and air-cool to room temperature to obtain a magnesium alloy billet.

[0039] 2) Preheat the homogenized magnesium alloy billet to 450-460°C, then put it into the extrusion barrel and carry out hot extrusion in the extrusion machine, the extrusion temperature is 450°C, the extrusion ratio is 30:1, and the extrusion The blank after pressing is 56mm wide and 3mm thick.

[0040] 3) The extruded billet is cold-rolled one pass along the extrusion direction, with a reduction of 19% per pass, and then annealed. The annealing temperature is 350°C and the annealing time is 1h, which is the low anisotropy and high plastic magnesium alloy.

[0041] Its ultimate tensile strength at room temperature along RD (rolling direction) of the magnesium alloy gained in the present embodiment is 228MPa, and the elongation after stretching is 41.6%. The elongation after breaking was 45....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com