Fire extinguishing device for fire engineering

A fire-extinguishing device and engineering technology, applied in fire rescue and other directions, can solve the problems of re-ignition of combustion materials and secondary fire disasters, and achieve the effects of preventing re-ignition, avoiding secondary fires, and preventing powder flying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

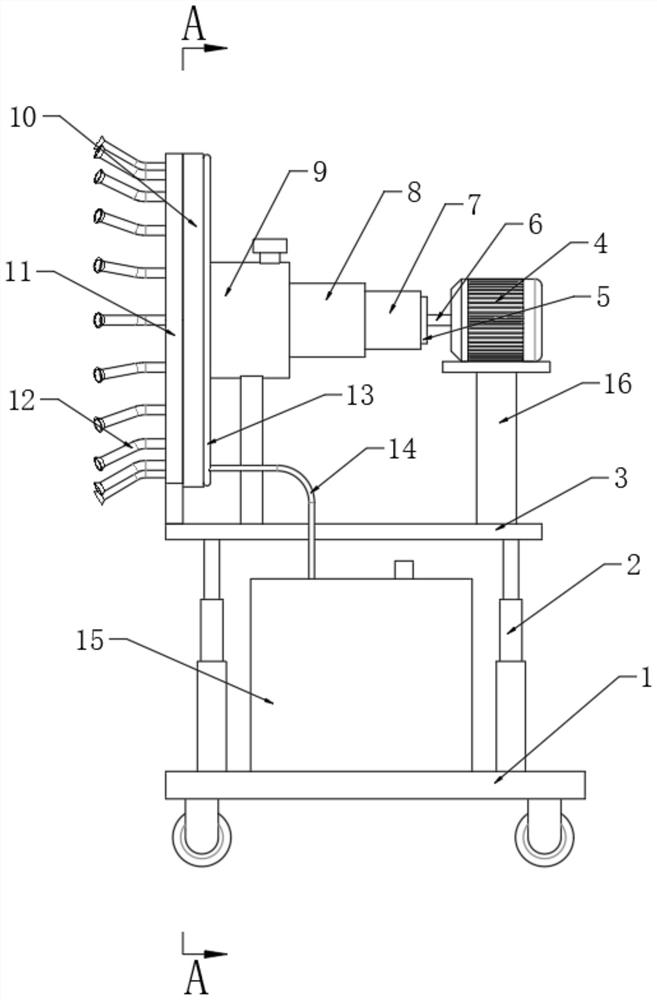

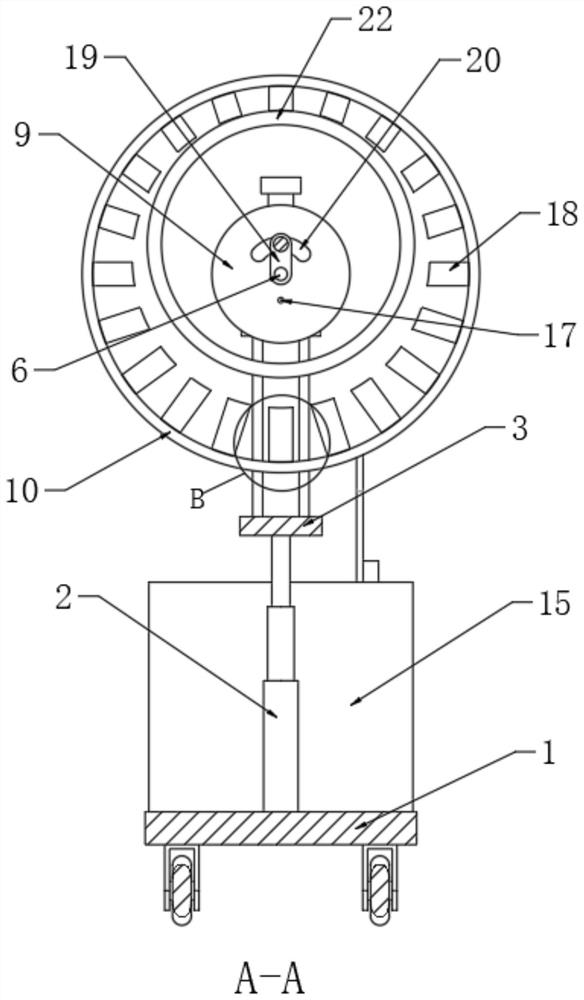

[0029] Embodiment 1, when a fire breaks out, the device is moved to the fire extinguishing site, and then the height of the lifting plate 3 can be adjusted through the external structure, so that the nozzle 12 can be aimed at the top of the fire source, and then the nozzle 12 can spray to the fire. Water, to reduce the surface temperature of the combustibles, make it drop to below the ignition point, thereby play the effect of fire extinguishing, and the nozzles 12 can be made to all face outwards, and because the nozzles 12 are distributed in a ring, therefore, the water sprayed by the nozzles 12 A cone-shaped water mist will be formed, which can also play a certain role in blocking the toxic gas produced by combustion and the ashes in the air, preventing it from floating randomly.

[0030] At the same time, inflate the powder spraying box 9 through the inflatable assembly, then the air pressure in the powder spraying box 9 becomes larger, and the flame-retardant powder in it ...

Embodiment 2

[0042] Embodiment 2, different from Embodiment 1, is that the inflatable assembly adopts the air pump 30, by starting the air pump 30, and then inflating the powder spraying box 9 through the air delivery pipe 29, so compared with the inflatable assembly of Embodiment 1, it will make Inflation is relatively continuous and stable, but at the same time, the energy consumption will also increase accordingly, and this can make the air pressure in the powder spraying box 9 larger than that in Embodiment 1, so that the distance that the powder can be sprayed becomes farther, and then can Adapted to fight larger fires.

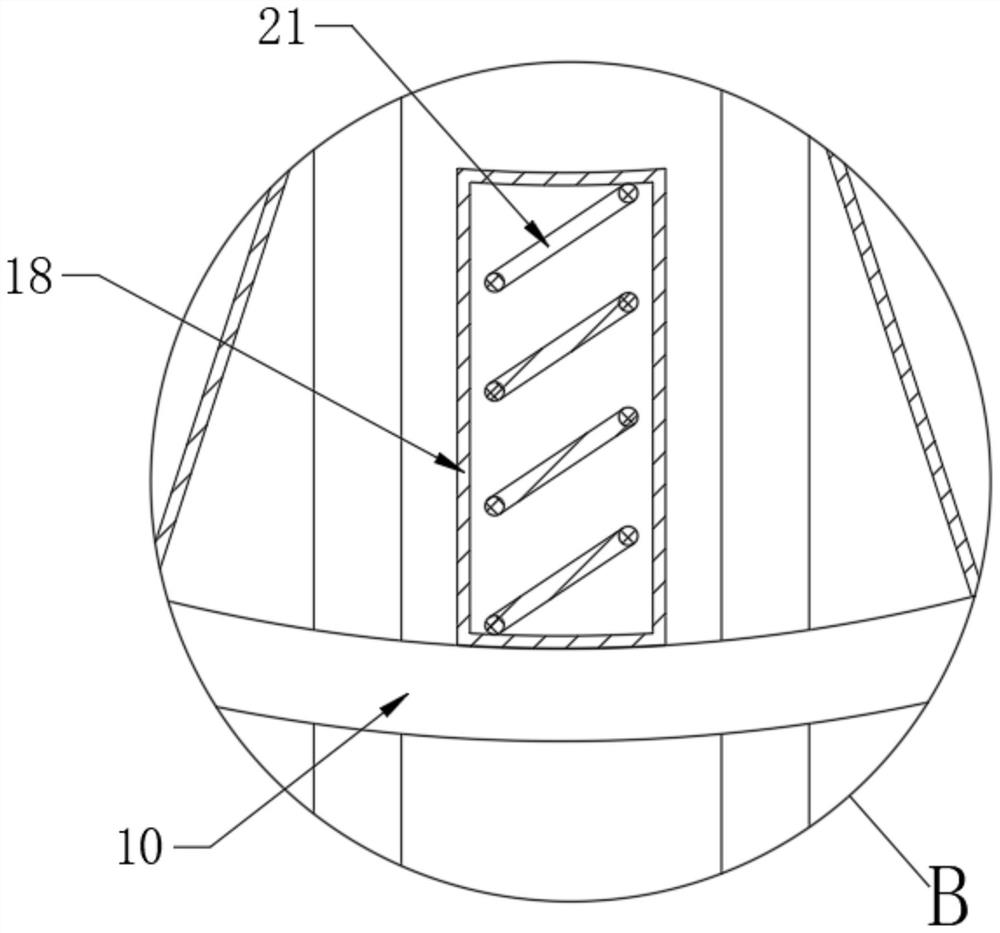

[0043] Further, the rotating shaft 6 is fixed with a cylinder 5 away from the outer wall of the powder spraying box 9, and the outer wall of the cylinder 5 is provided with a curved groove 25, and the piston plate 24 is fixed with a movable tube 7 near the outer wall of the cylinder 5, and the movable tube 7 is sleeved on the cylindrical surface. 5. The outer wall an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com