Epidemic prevention mask and preparation method thereof

A mask and breathing valve technology, applied in the field of epidemic prevention masks and their preparation, can solve the problem that masks cannot be recycled by aseptic folding and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

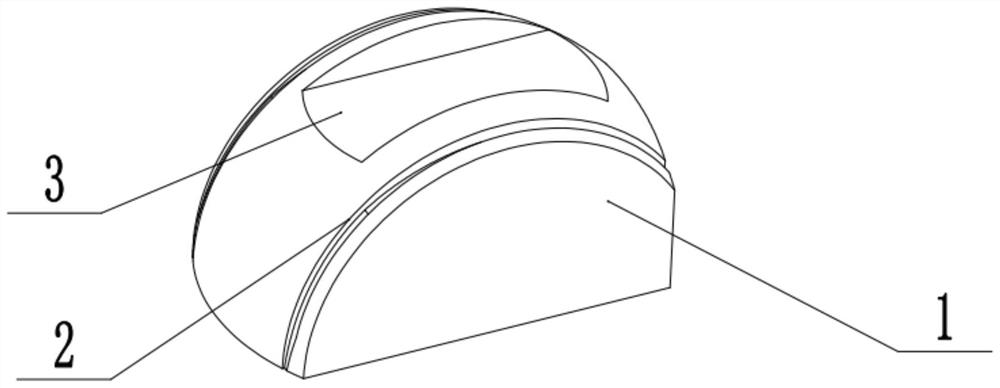

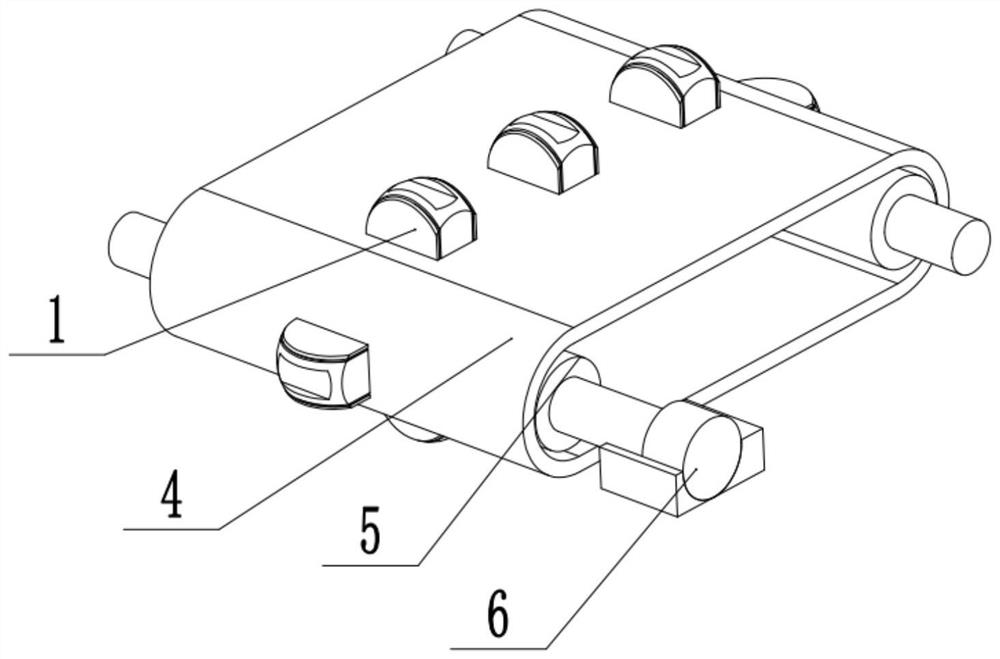

[0029] As shown in the implementation shown here,

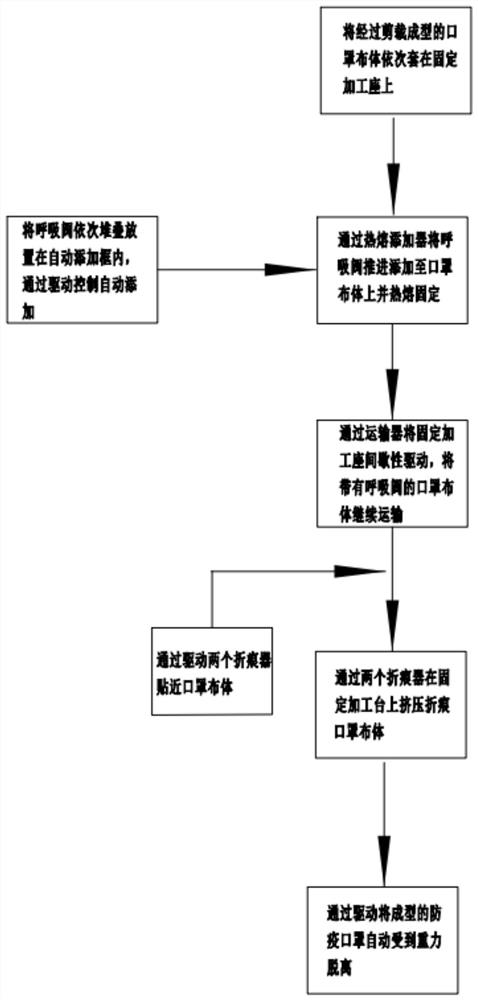

[0030] By automatically nesting the multi-layer mask cloth body on the fixed processing seat, waiting for processing, stacking the breathing valve in the automatic adding frame, waiting for automatic adding, and passing through the intermittent transportation of the transporter, the mask cloth with The fixed processing seat of the body moves to the lower end of the hot melt adder, and at the same time pushes a breathing valve in the automatic adding frame to the designated position by driving, and pushes the breathing valve to the mask cloth body and On the fixed processing seat, the breathing valve is hot-melt extruded by continuous hot-melt adder, and the corresponding sealing ring is melted, so that it is sealed and fixed in the mask cloth body; through the continuous gap transportation of the transporter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com