Thermal change self-early warning type mutual inductor

A transformer and pre-sinking technology, applied in the field of transformers, can solve problems such as service life impact, potential safety hazards, and low heat dissipation, and achieve the effects of reducing the impact of service life, reducing potential safety hazards, and improving early warning effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

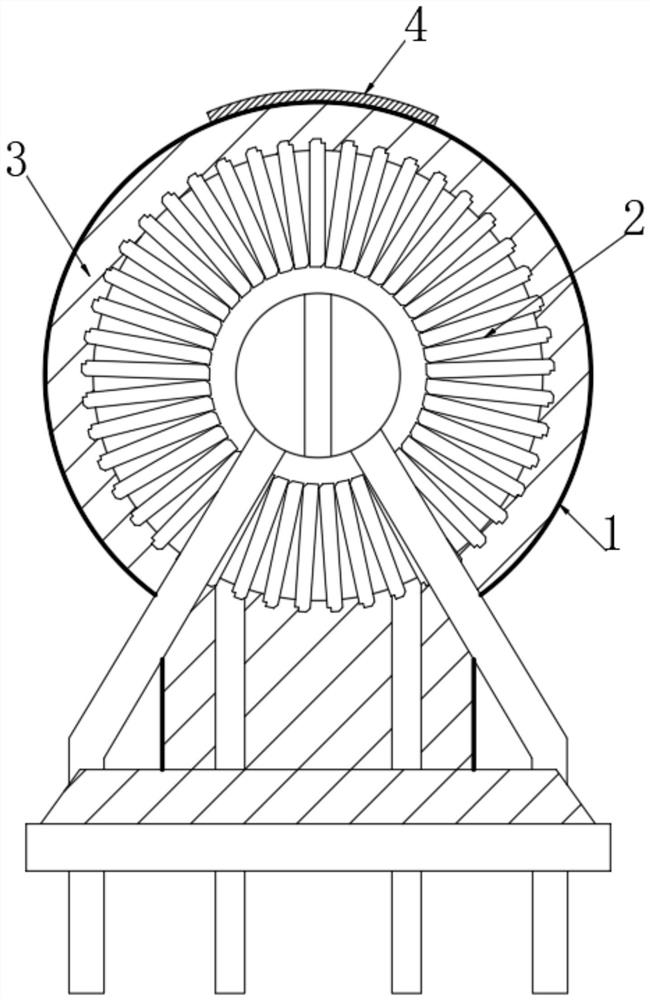

[0036] see figure 1 , a heat-changing self-warning transformer, including a magnetic core 2, a casing 1 located outside the magnetic core 2, and an epoxy resin layer 3 poured between the casing 1 and the magnetic core 2, and a double variable transformer is attached to the upper end of the casing 1 Precautionary note 4.

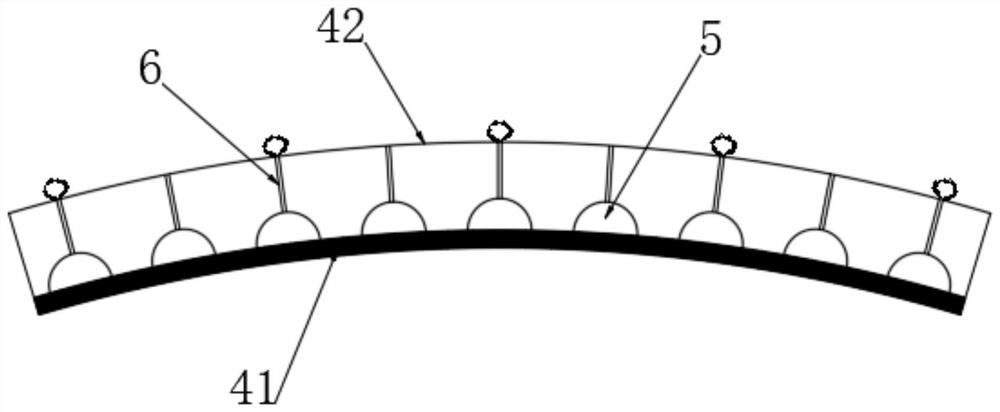

[0037] see figure 2 The double variable warning strip 4 includes a bottom adhesive sheet 41 attached to the shell 1, an outer flat layer 42 outside the bottom adhesive sheet 41, and a plurality of evenly distributed inner supports are arranged between the bottom adhesive sheet 41 and the outer flat layer 42 The hemispherical rod 5 and the plurality of heat sink variable rods 6, the plurality of heat sink variable rods 6 and the inner support hemispherical rods 5 are spaced apart from each other, and the upper ends of the plurality of heat sink variable rods 6 are fixed through the outer flat layer 42 and extend to Outside the outer leveling layer 42, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com