Battery module airtightness test subassembly

A technology for air tightness test and battery module, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement and measuring the increase and deceleration rate of fluid, etc., can solve the problems of slow test speed, bad and low efficiency, To achieve the effect of improving safety, improving convenience and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

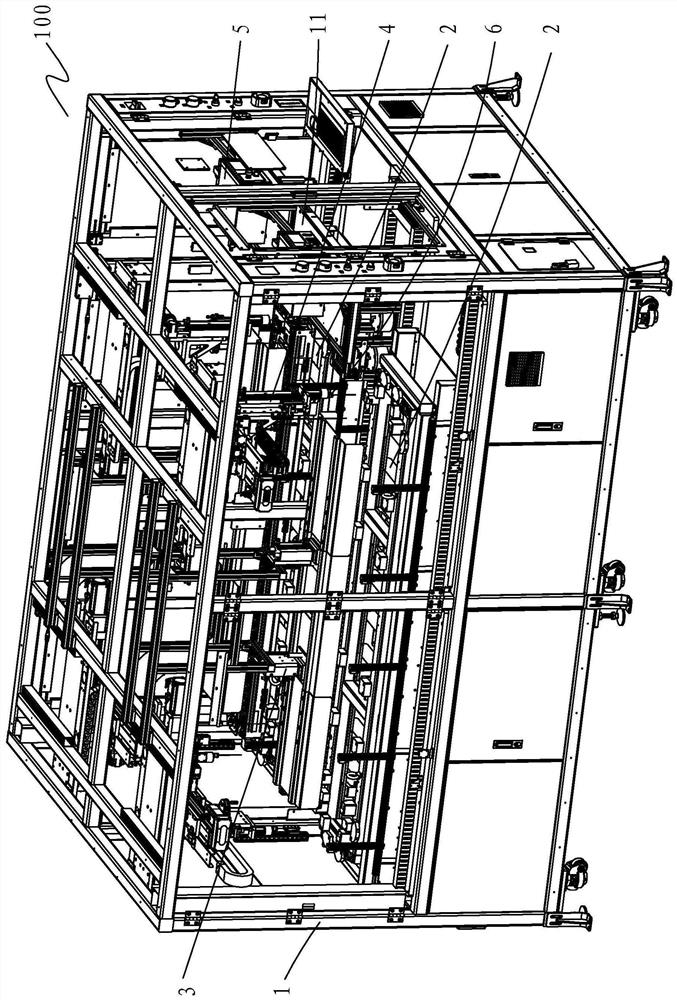

[0055] The embodiment of the present invention provides a battery module airtightness test unit 100, which solves the problem of slow manual test speed in the prior art, manual plugging and unplugging of the airtight plug is not easy to judge whether it is in place, and the semi-automatic test is easy to misuse and cause danger. , and the technical problem that only one battery module can be tested at a time is low in efficiency, and the technical effect of greatly improving the quality, safety and efficiency of the battery module air tightness test has been achieved.

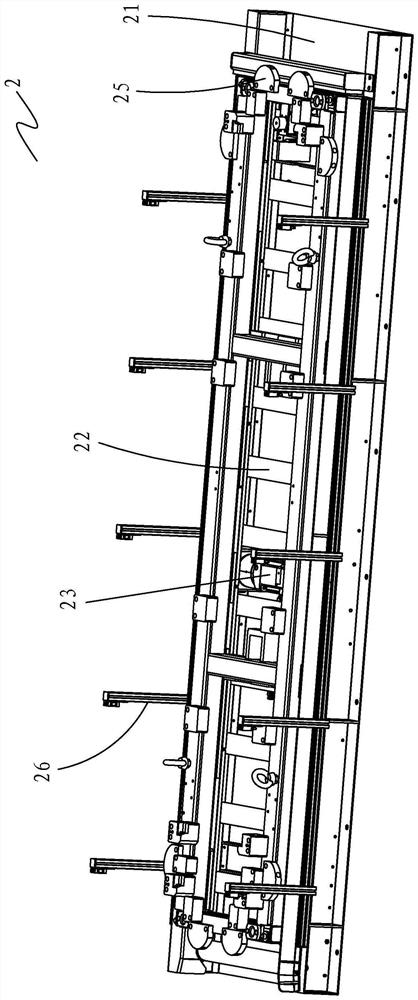

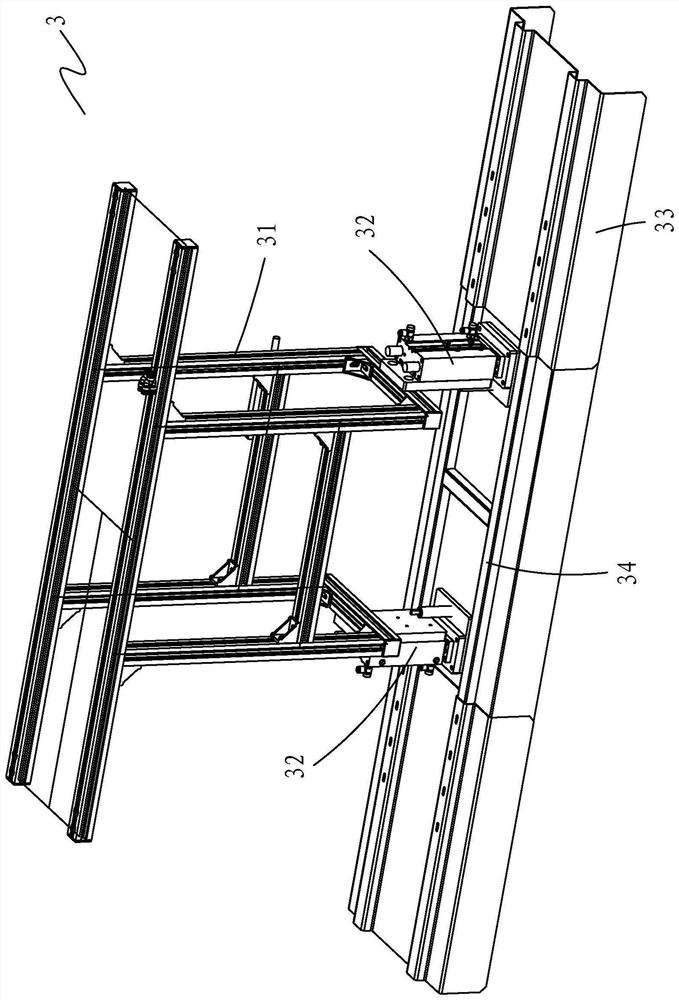

[0056] The technical solution in the embodiment of the present invention is to solve the above-mentioned problems, and the general idea is as follows: the battery module 12 is positioned by setting the drum assembly line 2, the camera 8 and the photoelectric sensor 10, and the plug-in mechanism 4 is set to automatically insert the airtight plug 6 On the airtight jack 121 of the battery module 12, avoid the airti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com