Anti-static textile fabric cleaning and flattening device

A textile fabric and anti-static technology, applied in the field of textile fabrics, can solve the problems of dust sticking to the surface, electrostatic reaction, fire, loss, etc., and achieve the effect of simple integrated structure, thorough cleaning, and anti-static

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

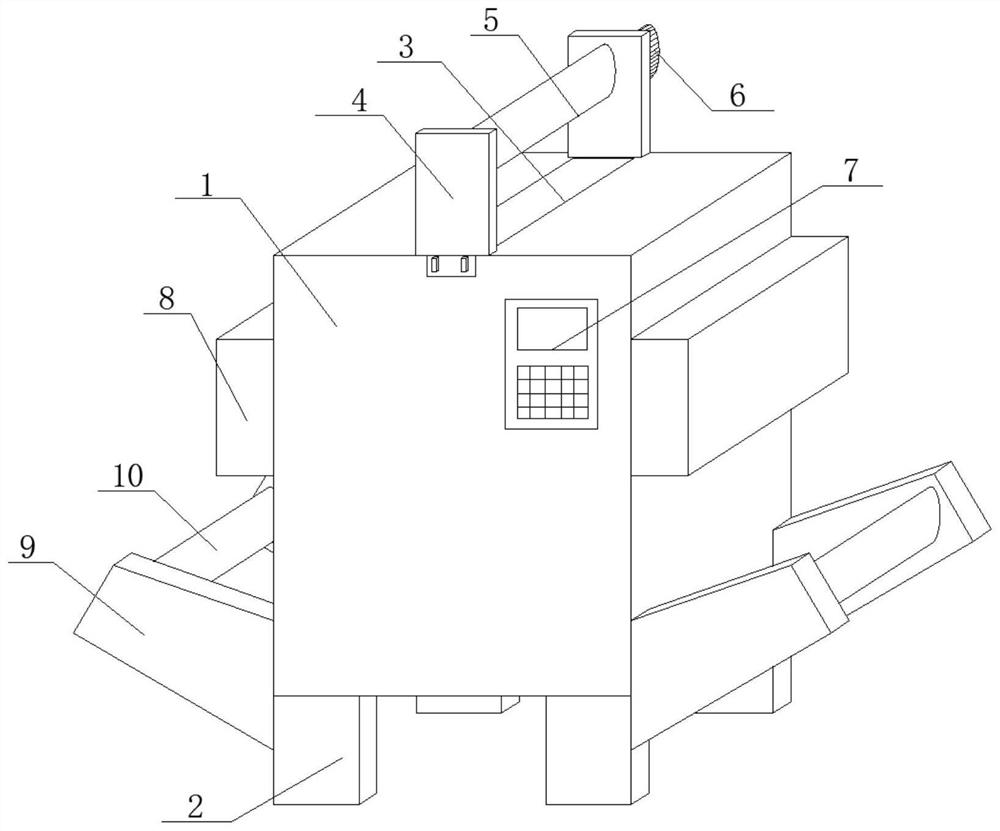

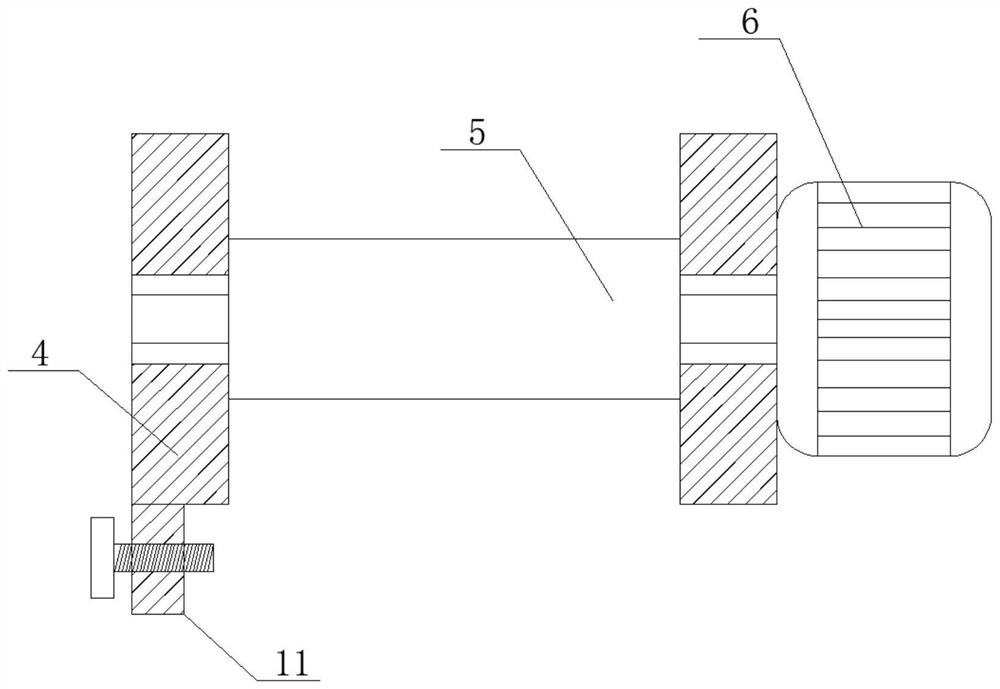

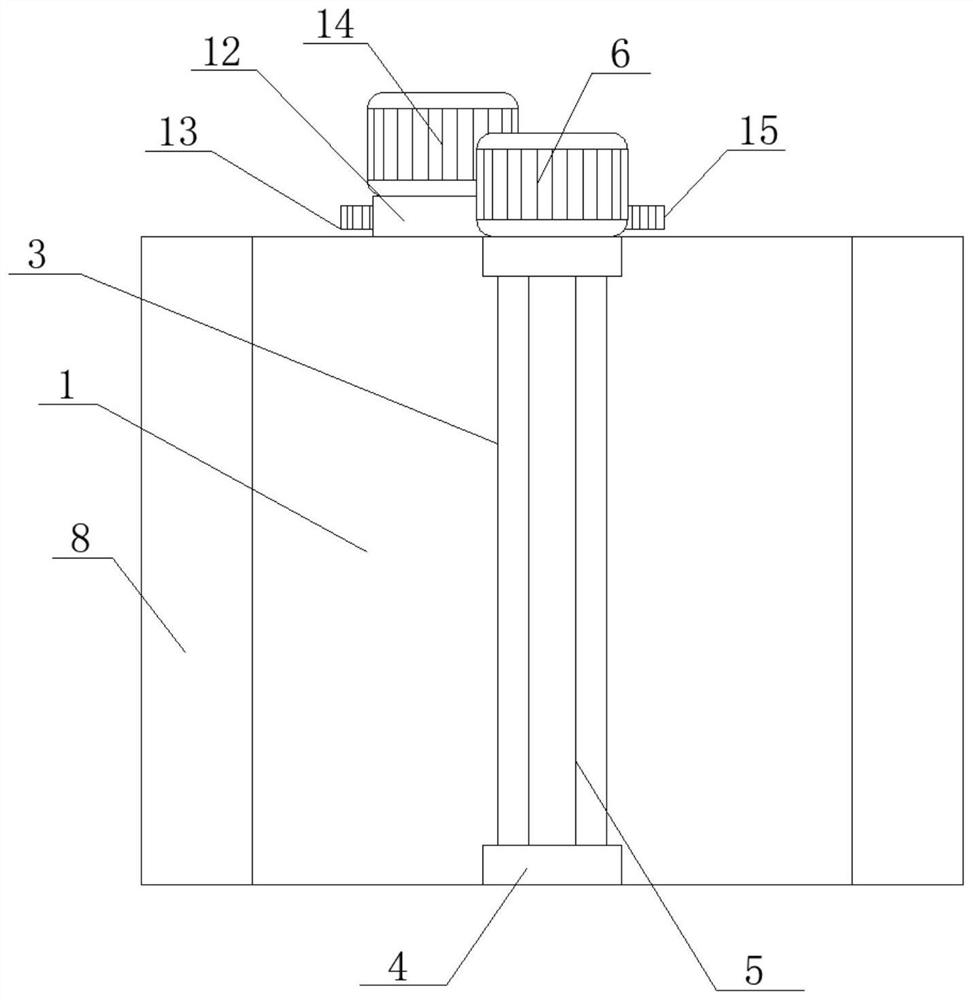

[0027] see Figure 1-3, in the embodiment of the present invention, a kind of antistatic textile cloth cleans leveling device, comprises main treatment box 1, and the bottom surface of main treatment box 1 is vertically welded with support pole 2 downwards, and the top surface of main treatment box 1 is provided with feeding The top groove 3, the number of support poles 2 is four, and the four support poles 2 are arranged parallel to each other, and the tops of the four support poles 2 are fixed vertically upwards at the four corners of the bottom surface of the main processing box 1 , the feeding top trough 3 is set at the center of the top surface of the main processing box 1, and the inside of the feeding top chute 3 is kept in communication with the inside of the main processing box 1, and the top surface of the main processing box 1 is vertically provided with a supporting side Plate 4, the side between the supporting side plates 4 is plugged with the main material shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com