Self-supporting two-dimensional selenium oxide nanosheet array and preparation method thereof

A technology of nanosheet arrays and oxides, which is applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of difficult preparation and transfer of two-dimensional selenium oxide nanosheets, and achieve high quality and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of the self-supporting two-dimensional selenium oxide nanosheet array of this embodiment comprises the following steps:

[0033] (1) A single temperature zone horizontal tube furnace is used as the vapor deposition equipment. The tube length of the horizontal tube furnace is 120cm, the outer diameter is 25mm, the tube wall thickness is 1.8mm, and the range of the constant temperature zone is 5cm. In the upstream low temperature zone, bismuth oxide is placed in the central high temperature zone, and the sodium chloride substrate is placed in the downstream low temperature zone. The temperature in the upstream low temperature zone is 500°C, the temperature in the central high temperature zone is 600°C, the temperature in the downstream deposition zone is 450°C, and the heating rate is 10°C / min. The mass ratio of bismuth selenide and bismuth oxide is 2:1.

[0034] (2) Wash with 700 sccm argon for one hour before heating to remove residual oxygen in...

Embodiment 2

[0038] The preparation method of the self-supporting two-dimensional selenium oxide nanosheet array of this embodiment comprises the following steps:

[0039] (1) A single temperature zone horizontal tube furnace is used as the vapor deposition equipment. The tube length of the horizontal tube furnace is 120cm, the outer diameter is 25mm, the tube wall thickness is 1.8mm, and the range of the constant temperature zone is 5cm. In the upstream low temperature zone, bismuth oxide is placed in the central high temperature zone, and the sodium chloride substrate is placed in the downstream low temperature zone. The temperature in the upstream low temperature zone is 520°C, the temperature in the central high temperature zone is 630°C, the temperature in the downstream deposition zone is 480°C, and the heating rate is 10°C / min. The mass ratio of bismuth selenide and bismuth oxide is 1.5:1.

[0040] (2) Wash with 700 sccm argon for one hour before heating to remove residual oxygen ...

Embodiment 3

[0044] The preparation method of the self-supporting two-dimensional selenium oxide nanosheet array in this example is the same as that in Example 1, except that the temperature in the central high temperature zone is 700°C, the heating rate is 20°C / min, and the reaction time is 60min.

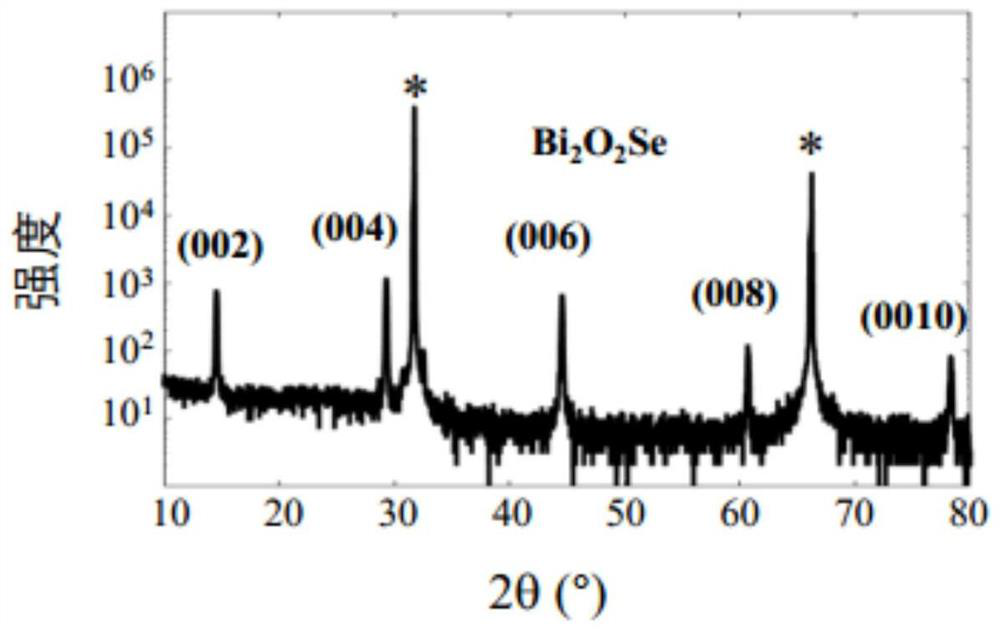

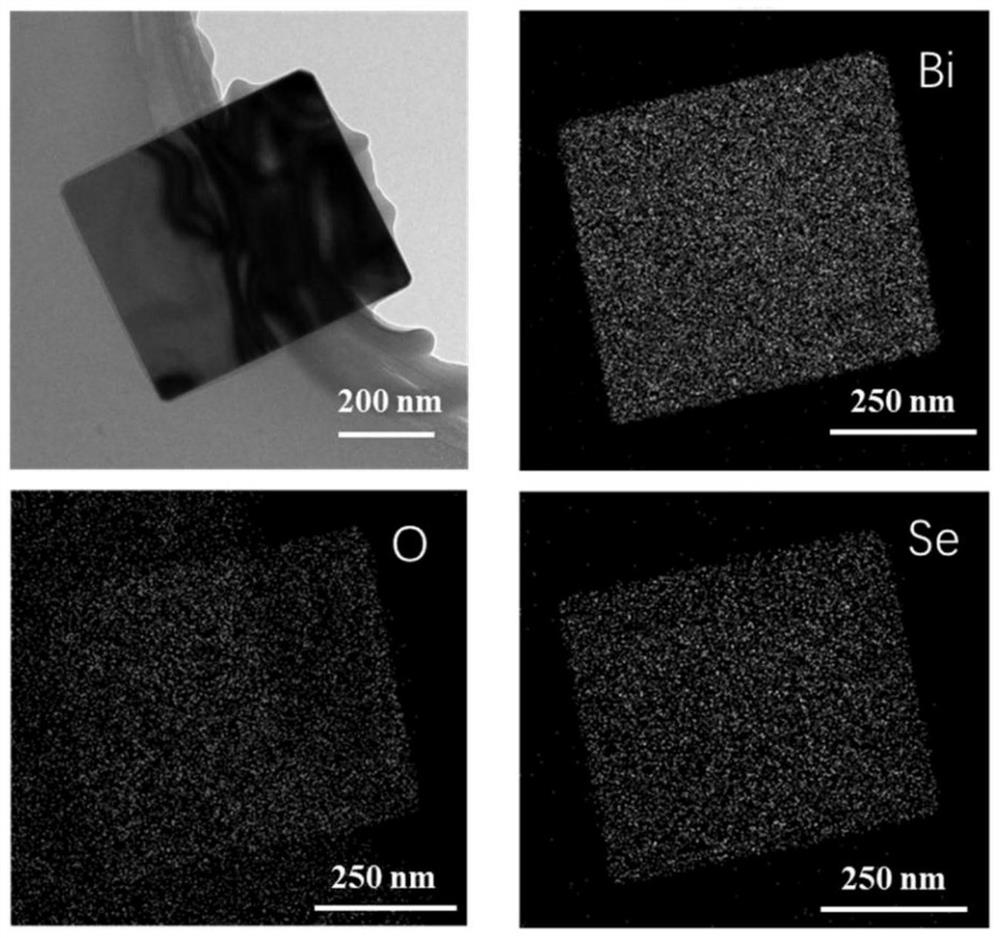

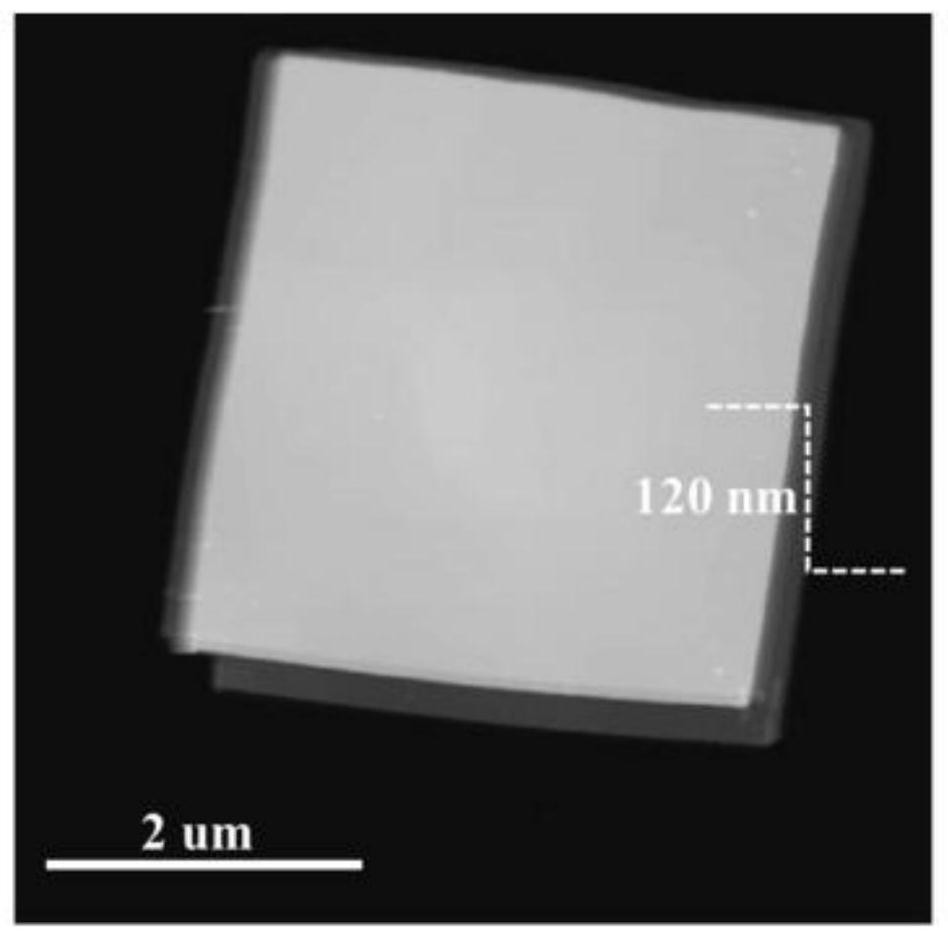

[0045] The self-supporting two-dimensional selenium oxide nanosheet array of the present invention is prepared by the preparation method of the two-dimensional selenium oxide nanosheet array in Example 1-3, and the obtained two-dimensional selenium oxide nanosheet has square and rectangular regular arrangements. Morphology, the lateral size is 2-6μm, and the thickness is 50-120nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com