Low-energy-consumption ammonia-carbon separation method

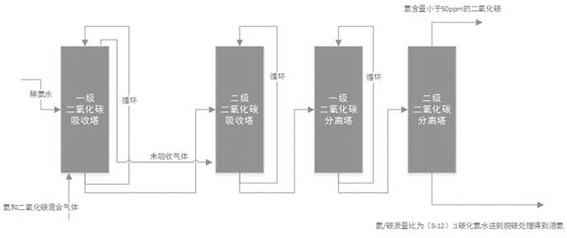

A technology of ammonia-carbon separation and low energy consumption, which is applied in the preparation/separation of ammonia, chemical instruments and methods, carbon compounds, etc. It can solve the problems of difficult operation and high energy consumption, and achieve energy consumption reduction, steam consumption reduction, and liquid reduction The effect of circulation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) The mixed gas containing ammonia and carbon dioxide (including NH 3 63%, CO 2 37%) into the bottom of the primary carbon dioxide absorption tower at 74000 L / min, and add dilute ammonia water with a concentration of 4wt% at 80L / min from the middle of the primary carbon dioxide absorption tower as the absorption liquid, and the mixed gas and dilute ammonia water are in the absorption tower Circulate and absorb in a countercurrent manner for 20 minutes;

[0025] (2) After the cycle is over, the absorption liquid in the primary carbon dioxide absorption tower (ammonia / carbon mass ratio is 3:1 carbonized ammonia water) is sent to the middle of the secondary carbon dioxide absorption tower at 80 L / min, and the top of the primary carbon dioxide absorption tower The unabsorbed gas (including NH 3 45%, CO 2 54%) into the bottom of the secondary carbon dioxide absorption tower at 50,000 L / min, and circulate and absorb in the absorption tower for 20 minutes in a counter...

Embodiment 2

[0028] ( ) Mixed gas containing ammonia and carbon dioxide (containing NH 3 60%, CO 2 39%) into the bottom of the primary carbon dioxide absorption tower at 75000 L / min, and add dilute ammonia water with a concentration of 3.5wt% from the middle of the primary carbon dioxide absorption tower at 60 L / min as the absorption liquid, and the mixed gas and dilute ammonia water are absorbed Circulate and absorb in the tower in a countercurrent manner for 40 min;

[0029] (2) After the cycle is over, the absorption liquid in the primary carbon dioxide absorption tower (the ammonia / carbon mass ratio is 4:1 carbonized ammonia water) is sent to the middle of the secondary carbon dioxide absorption tower at 60 L / min, and the top of the primary carbon dioxide absorption tower The unabsorbed gas (including NH 3 40%, CO 2 59%) into the bottom of the secondary carbon dioxide absorption tower at 50,000 L / min, and circulate and absorb in the absorption tower for 40 minutes in a countercu...

Embodiment 3

[0032](1) The mixed gas containing ammonia and carbon dioxide (including NH 3 63%, CO 2 38%) into the bottom of the primary carbon dioxide absorption tower at 77000 L / min, and add dilute ammonia water with a concentration of 5wt% from the middle of the primary carbon dioxide absorption tower at 50-100L / min as the absorption liquid, and the mixed gas and dilute ammonia water are Circulate absorption in the absorption tower for 60 minutes in a countercurrent manner;

[0033] (2) After the cycle is over, the absorption liquid in the primary carbon dioxide absorption tower (ammonia / carbon mass ratio is 3:1 carbonized ammonia water) is sent to the middle of the secondary carbon dioxide absorption tower at 100 L / min, and the top of the primary carbon dioxide absorption tower The unabsorbed gas (including NH 3 35%, CO 2 63%) into the bottom of the secondary carbon dioxide absorption tower at 50,000 L / min, and circulate and absorb in the absorption tower for 60 minutes in a cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com