Winding device for polyimide film production

A technology of polyimide film and winding device, which is applied in the direction of winding strip, thin material processing, transportation and packaging, etc., can solve the problem of poor dust removal effect, achieve precise control of cutting time, prevent falling off, prevent The effect of adsorbing dust again

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

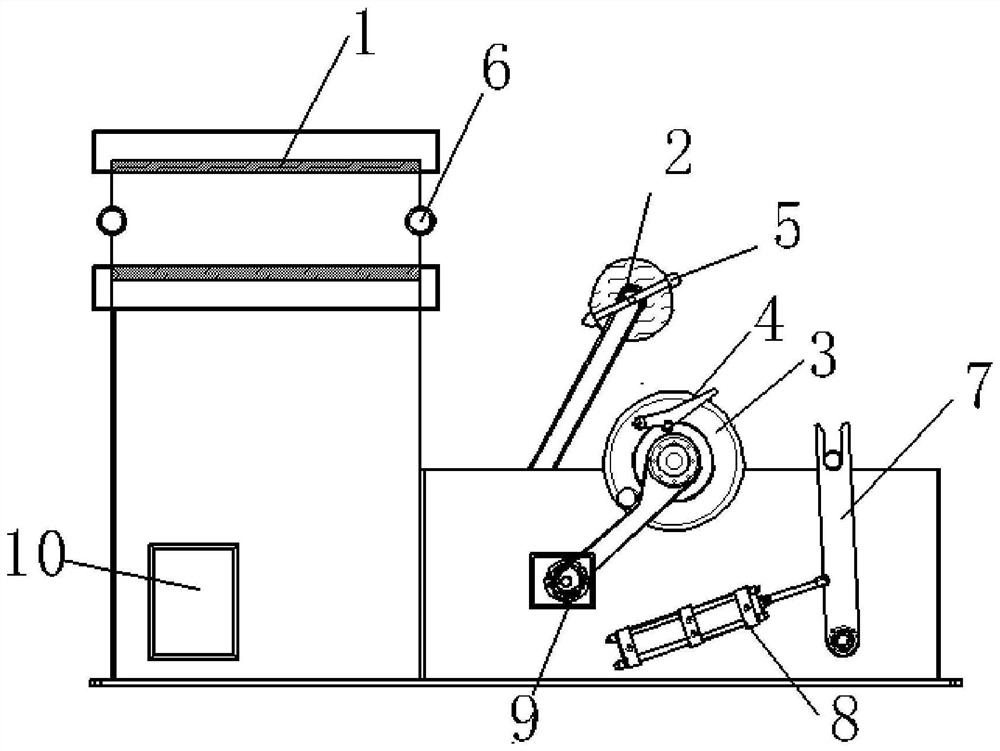

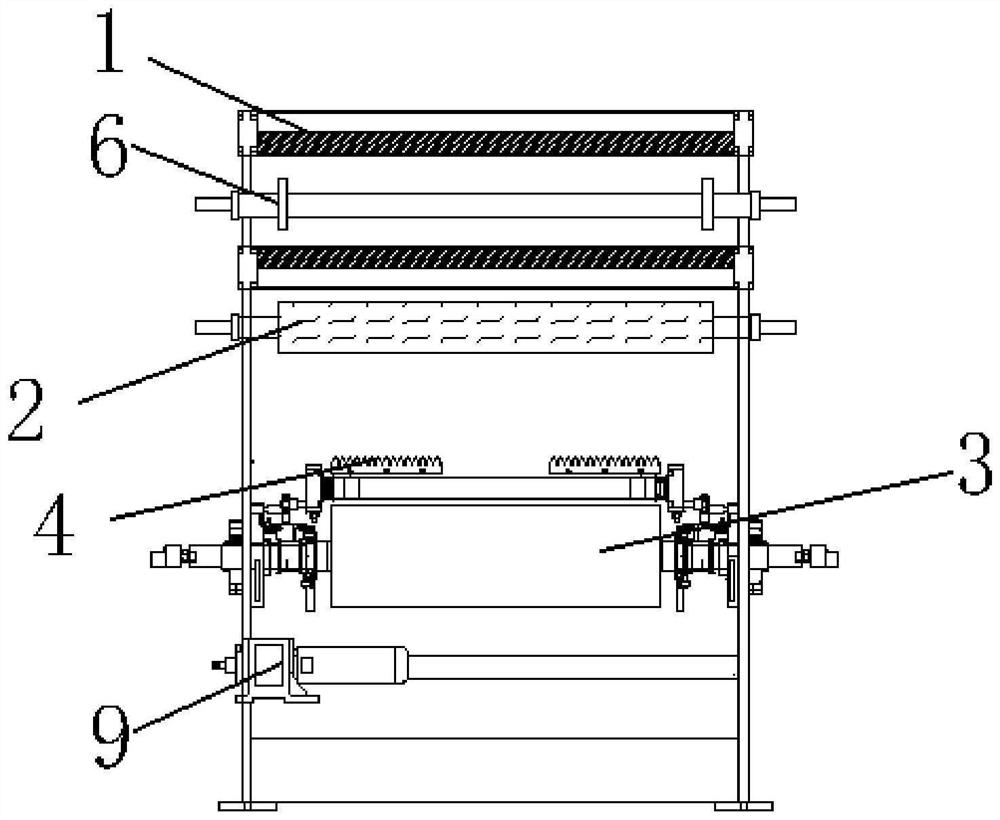

[0020] A rewinding device for polyimide film production, including an electrostatic precipitator 1, a movable rewinding support 7 and an active rubber roller 3; the upper end of the movable rewinding support 7 is provided with a groove for placing the winding The reel of the film; the cylinder 8 is installed at the bottom of the support, and the inclination angle of the support is adjusted through the expansion and contraction of the piston rod of the cylinder, thereby controlling the distance between it and the active rubber roller, and controlling the speed and tension of film winding;

[0021] In this embodiment, a winding motor 9 is arranged below the driving rubber roller 3, and the winding motor 9 is connected to the rotating shaft of the driving rubber roller 3 through a belt. By controlling the winding speed of the winding motor 9, the winding speed and The tension is adjusted, the control is flexible and convenient, and the production efficiency is effectively improved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com