Special strip for ultrahigh-voltage cable and production method of special strip

An ultra-high voltage, special technology, applied in electronic equipment, insulated cables, chemical instruments and methods, etc., can solve the problems of poor flame retardant and anti-static function, poor applicability, poor load-bearing capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

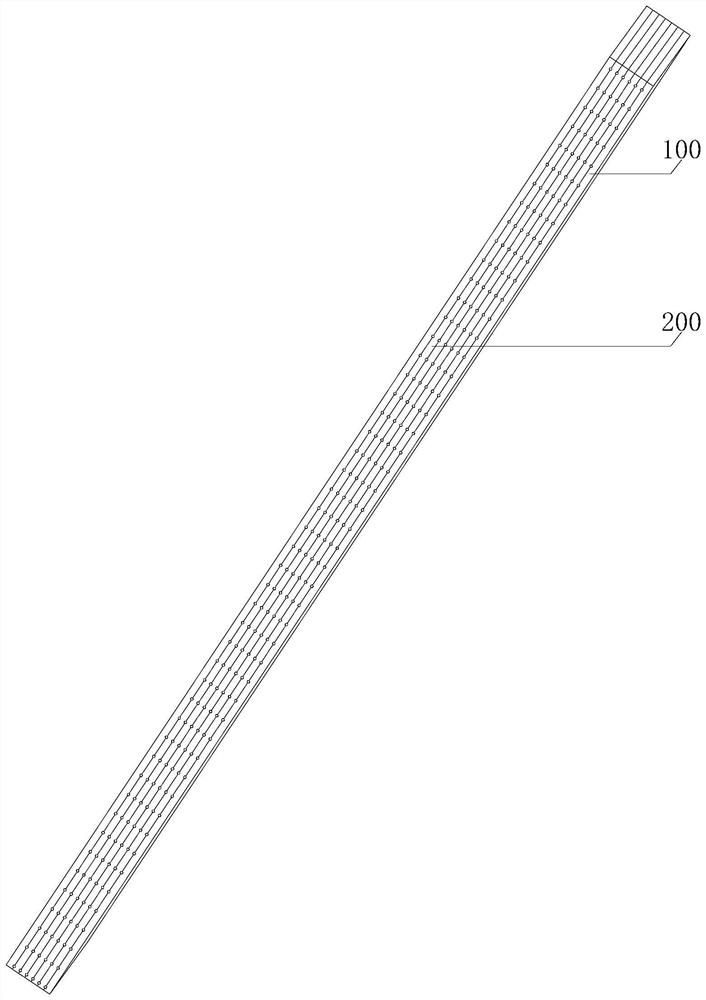

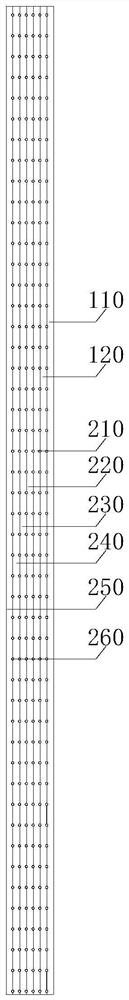

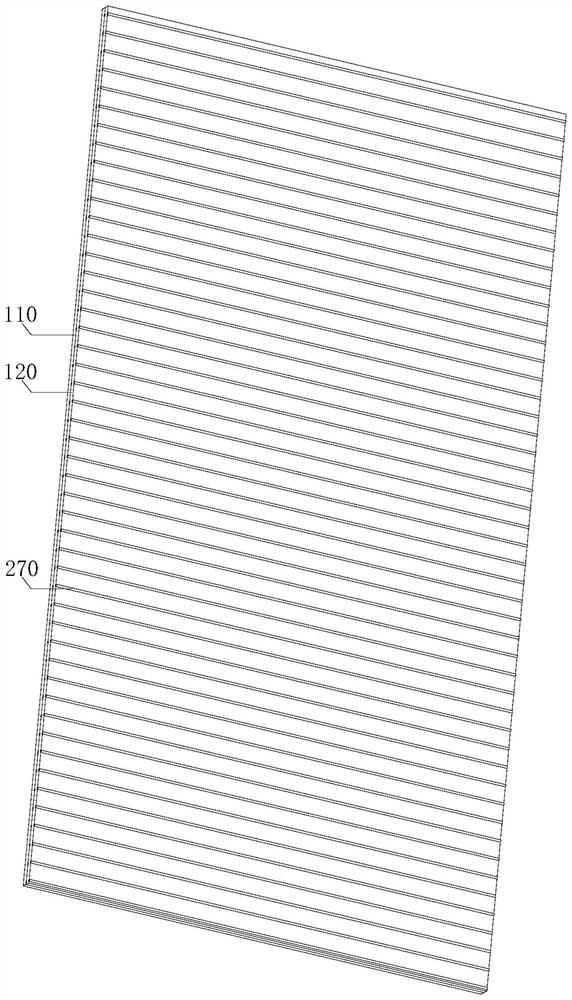

[0032] see Figure 1-4 , the present invention provides a special tape for extra-high voltage cables, including a basic component 100 and a strengthening component 200 . The reinforcing component 200 is fixed on the basic component 100. The special strip has the advantages of flame retardancy, tensile strength, insulation, antistatic, wear resistance, strong load-bearing capacity, strong reversible deformation and high elasticity, which improves the application of the special strip. sex.

[0033] see Figure 1-3 , the basic component 100 includes a nylon layer 110 and a rubber layer 120, the rubber layer 120 is pasted on the outer wall of the nylon layer 110, the nylon layer 110 is a polyamide layer, and the polyamide layer has high strength, high mechanical modulus, low creep, Strong wear resistance and fatigue resistance, chemical resistance, electrical resistance, flame resistance, weather resistance, good dimensional stability, etc. The rubber layer 120 is an isoprene ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com