Pneumatic numerical control shot blasting machine

A kind of shot blasting machine, pneumatic technology, applied in the direction of used abrasive processing device, solid separation, magnetic separation, etc., can solve the impact of steel shot on the effect of shot blasting, steel shot stuck, decrease of mesh filter effect, etc. problem, achieve the effect of reducing maintenance cost and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

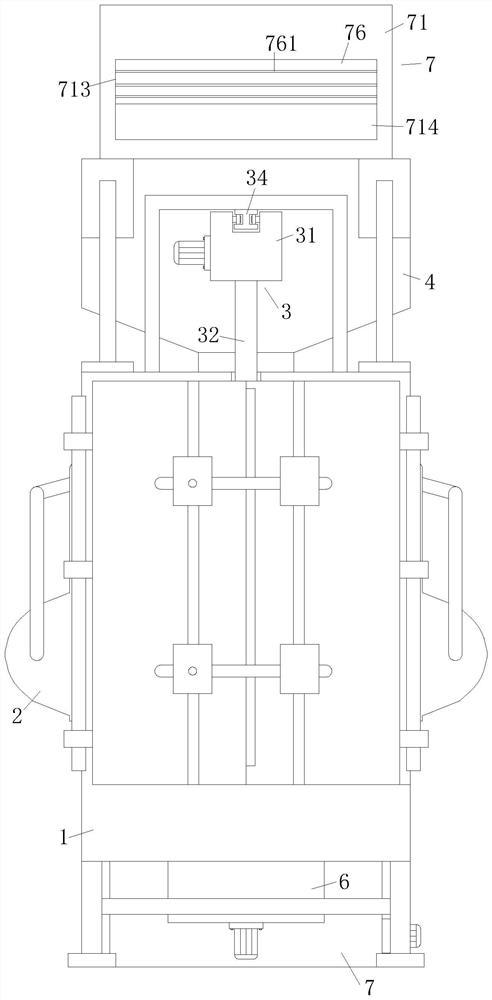

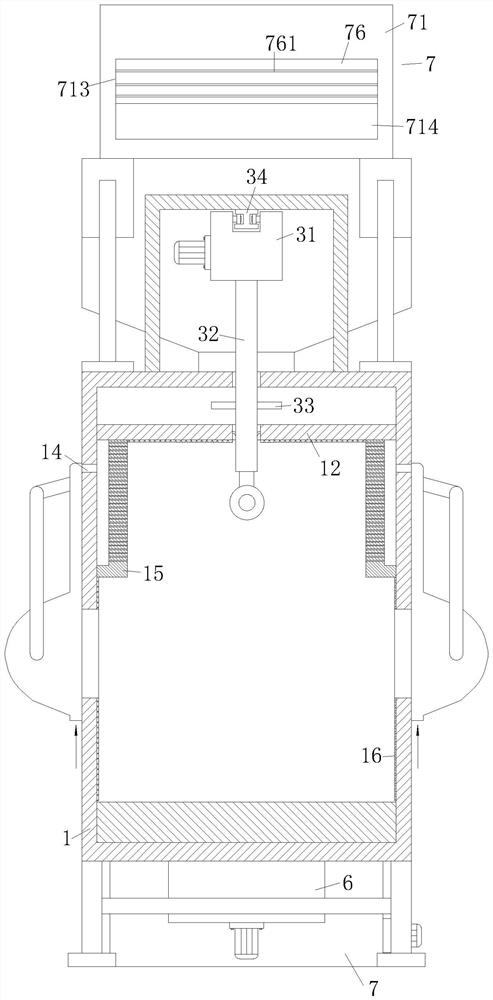

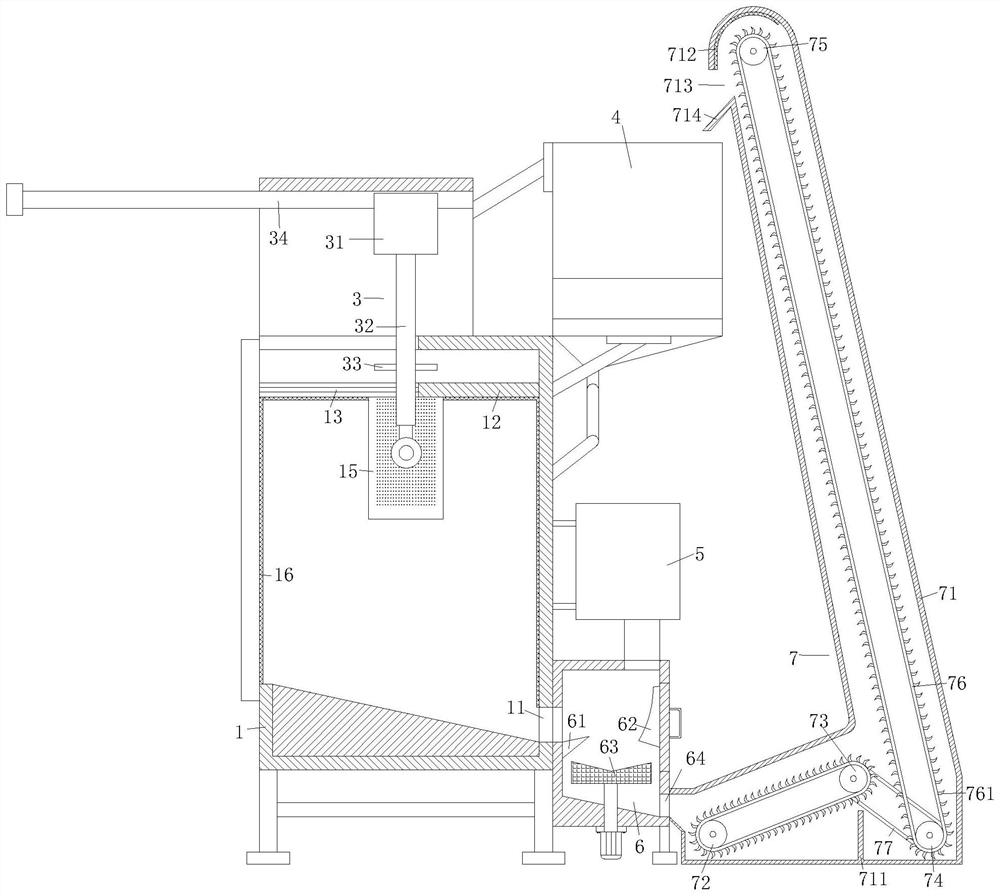

[0026] As an embodiment of the present invention, the hook assembly 3 includes a motor, a control box 31, a hook 32 and an annular plate 33, the hook assembly 3 is arranged on the top of the box body 1, and the top of the box body 1 is fixedly connected with a fixed frame, and the fixed I-shaped guide rails 34 are arranged front and rear at the center of the frame top, and the I-shaped guide rails 34 are fixedly connected with the top of the fixed frame. The control box 31 is slidingly connected with the I-shaped guide rails 34 through pulleys. 31 can realize three motion states through the motor, one is that the control box itself carries the hook 32 to enter and exit the box 1, the other is to control the lifting of the hook 32, and the third is the overall rotation of the hook 32, so as to realize the replacement of the shot blasting workpiece The top of the box body 1 is provided with a baffle plate 12, the baffle plate 12 is fixedly connected with the side walls around the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com