Wafer laser coding method and wafer laser coding system

A laser beam and laser light source technology, applied in laser welding equipment, electrical components, circuits, etc., can solve the problems of code recognition difficulty, poor code effect, poor anti-counterfeiting, etc., and achieve good code position consistency and low cost , good anti-counterfeiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

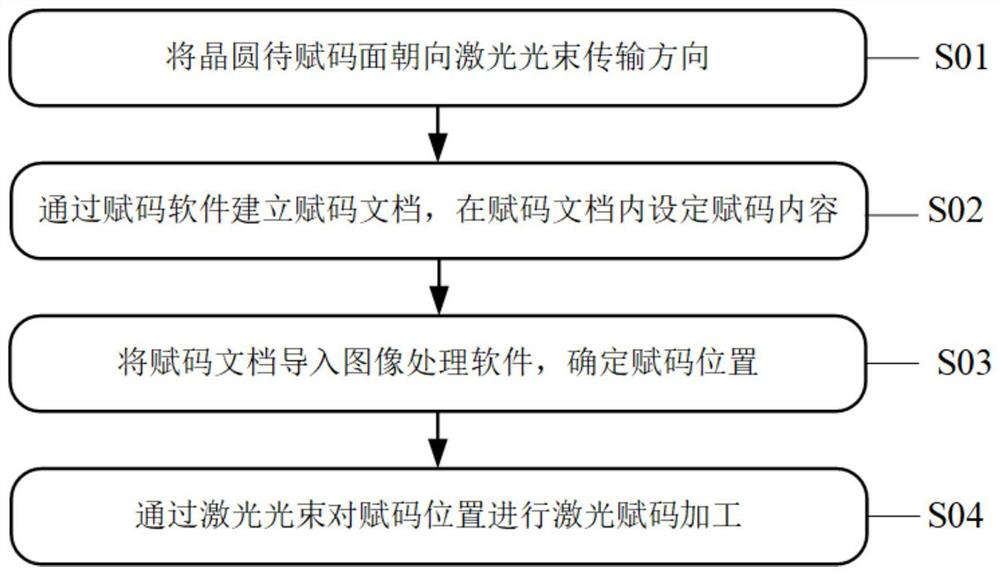

[0037] see figure 1 , a wafer laser coding method, comprising the following steps:

[0038] Step S01, facing the to-be-coded surface of the wafer 1 towards the transmission direction of the laser beam;

[0039] Step S02, using the coding software to create a coded file, and set the coded content in the coded file;

[0040] Step S03, import the coded document into the image processing software 2, and determine the coded position;

[0041] Step S04 , performing laser coding processing on the coding position by using a laser beam.

[0042] In some specific embodiments, after step S01 and before step S02, step S011 is set to adjust the size of the laser spot that the laser beam acts on the surface to be coded of the wafer 1;

[0043] In some specific embodiments, in step S011, by adjusting the distance between the laser light source of the laser beam and the surface to be coded of the wafer 1, the laser spot of the laser beam acting on the surface to be coded of the wafer 1 is ...

Embodiment 2

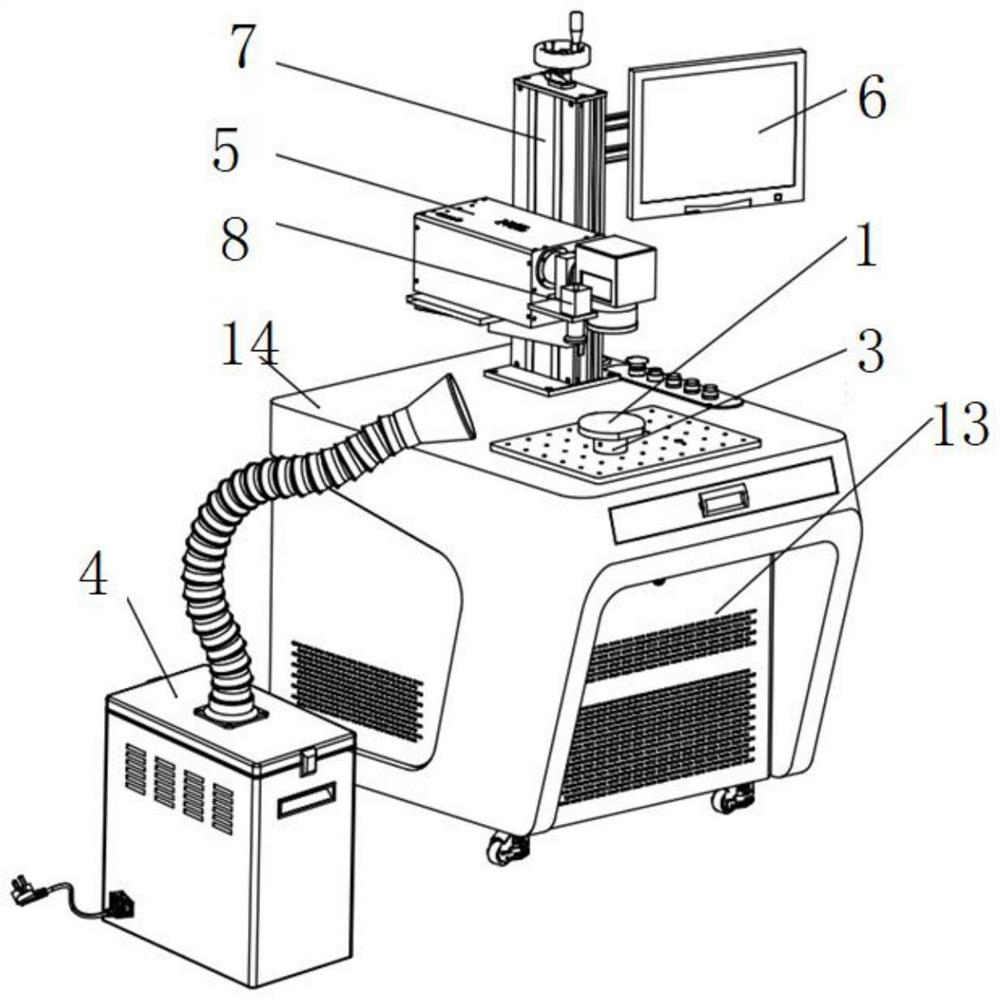

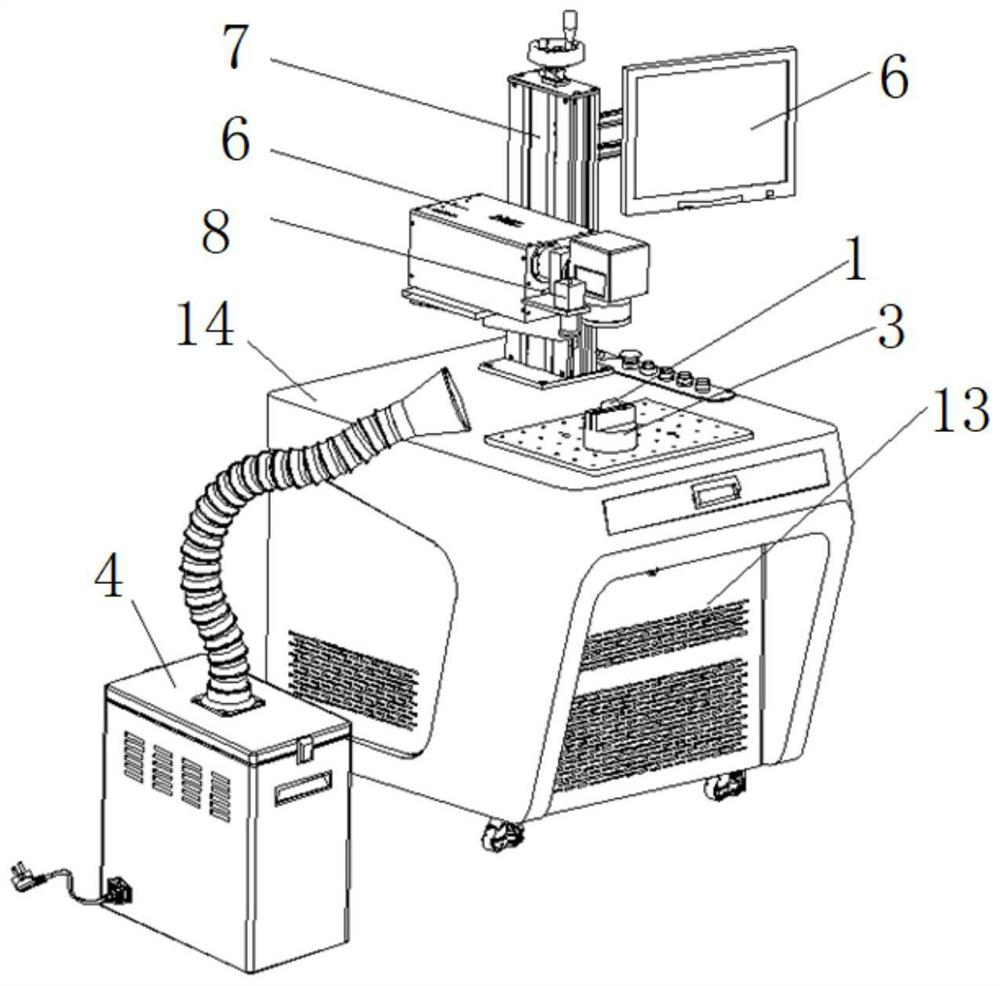

[0057] see figure 2 with image 3 , the present invention provides a wafer laser coding system for implementing the wafer laser coding method described in any one of Embodiment 1, the wafer laser coding system comprising:

[0058] The laser light source 5 is used to emit a laser beam for laser coding processing;

[0059] The industrial computer 6 is used to install coding software and image processing software 2. The coding software is used to control the filling method, filling distance, filling angle and laser parameters, and the image processing software 2 is used to determine the coding position.

[0060] In some specific embodiments, the laser light source 5 is installed on the distance adjustment device 7, and the distance adjustment device is used to adjust the distance between the laser light source 5 of the laser beam and the surface to be coded of the wafer 1, so as to realize the adjustment of the laser beam acting on The size of the laser spot on the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com