Pull-lever-type portable laser cleaning machine and cleaning method

A laser cleaning and rod-type technology, which is applied in the direction of cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems that large workpieces cannot be cleaned effectively, and achieve the effects of less dust, improved cleaning efficiency, and universal adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

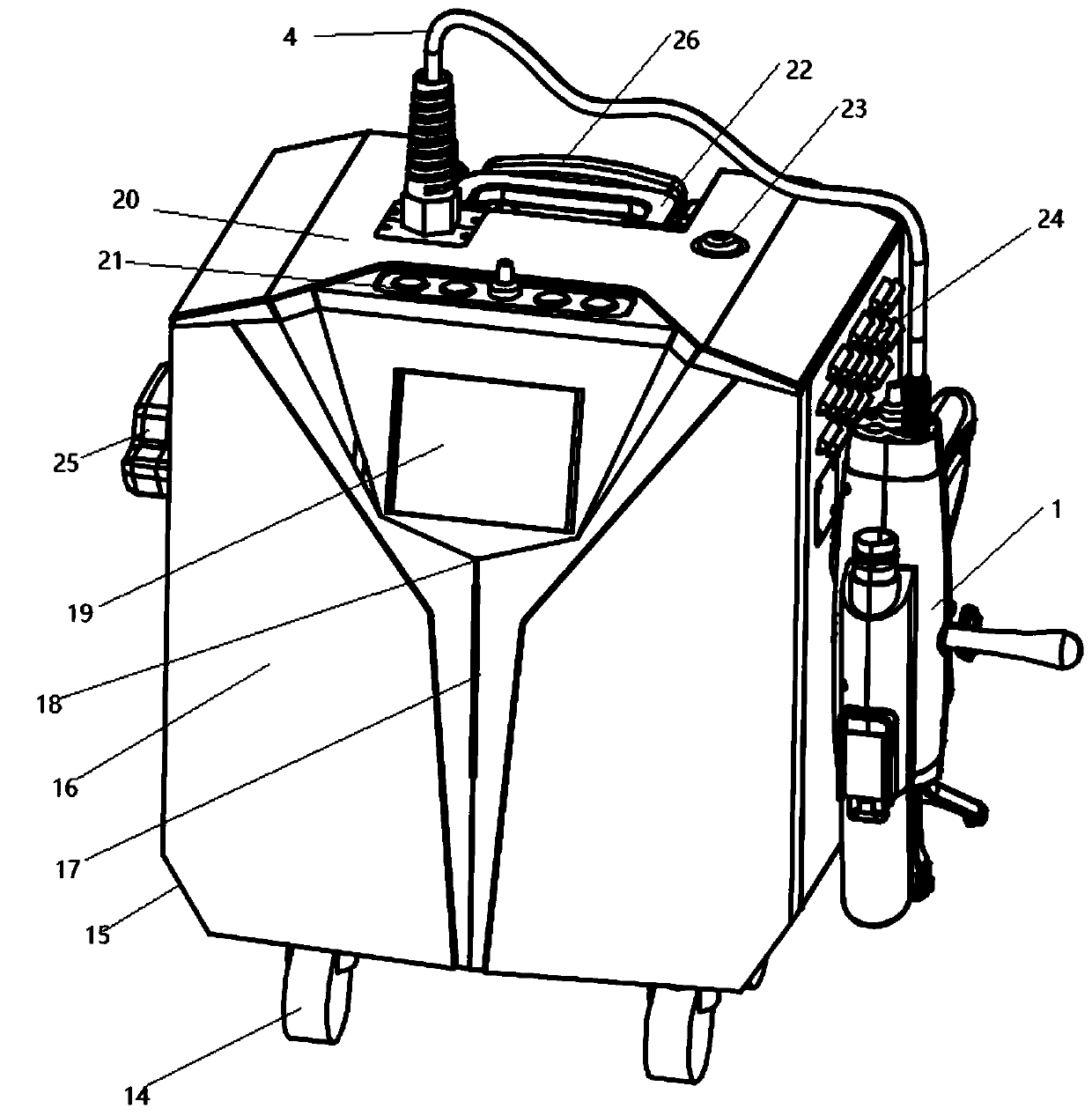

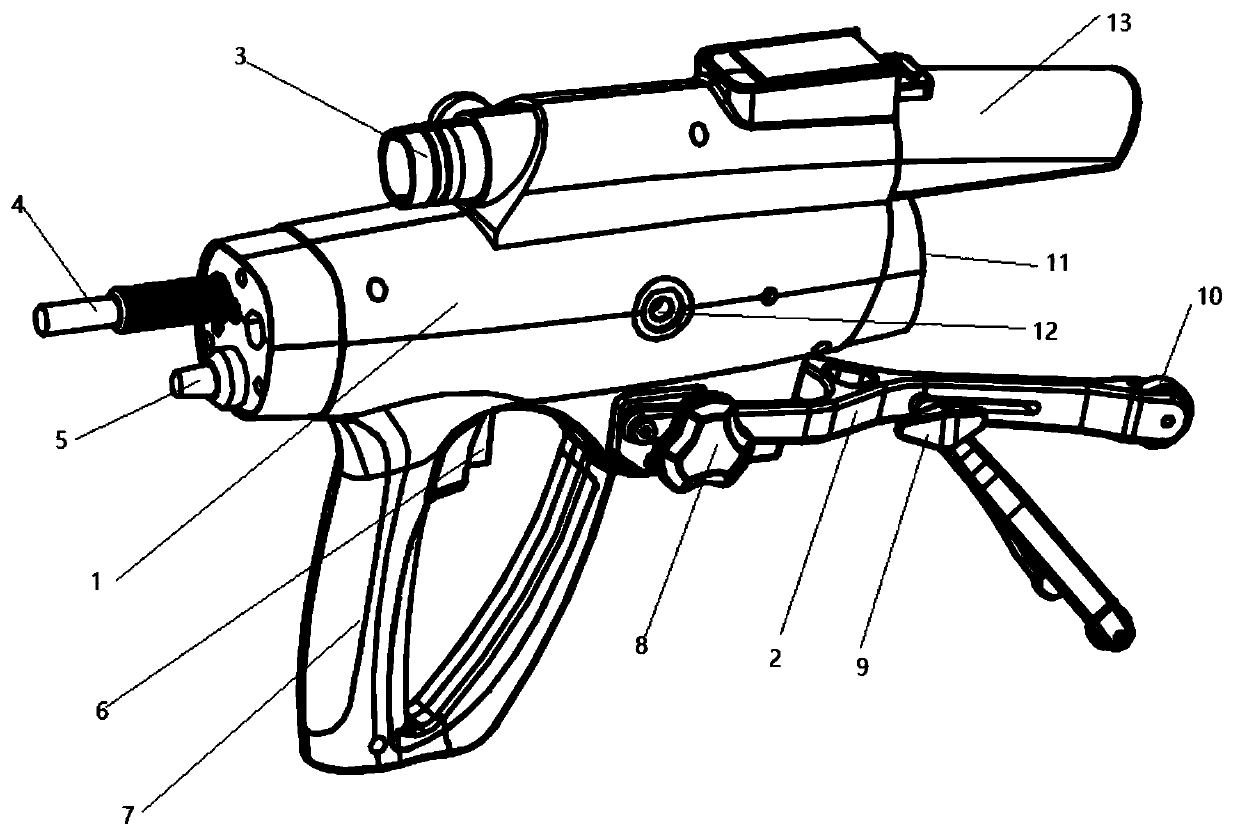

[0042] Taking the removal of rust on the steel plate as an example, the cleaning process of the laser cleaning machine is as follows: plug the laser cleaning machine into the power supply, turn on the key switch, click the laser emission switch on the indicator panel 21, pick up the laser cleaning head 1 and align it with the iron to be cleaned. rust on the plate, adjust the distance of the laser cleaning head to the distance from the iron plate, the distance is about the focal length, the optical path of the cleaning head forms an angle of about 75° with the iron plate, press the laser button The launch button scans back and forth on the iron plate to clean the rust. We can see that the red rust is quickly swept away, but the black rust on the iron plate is still slow to be removed, and it takes multiple scans to remove it.

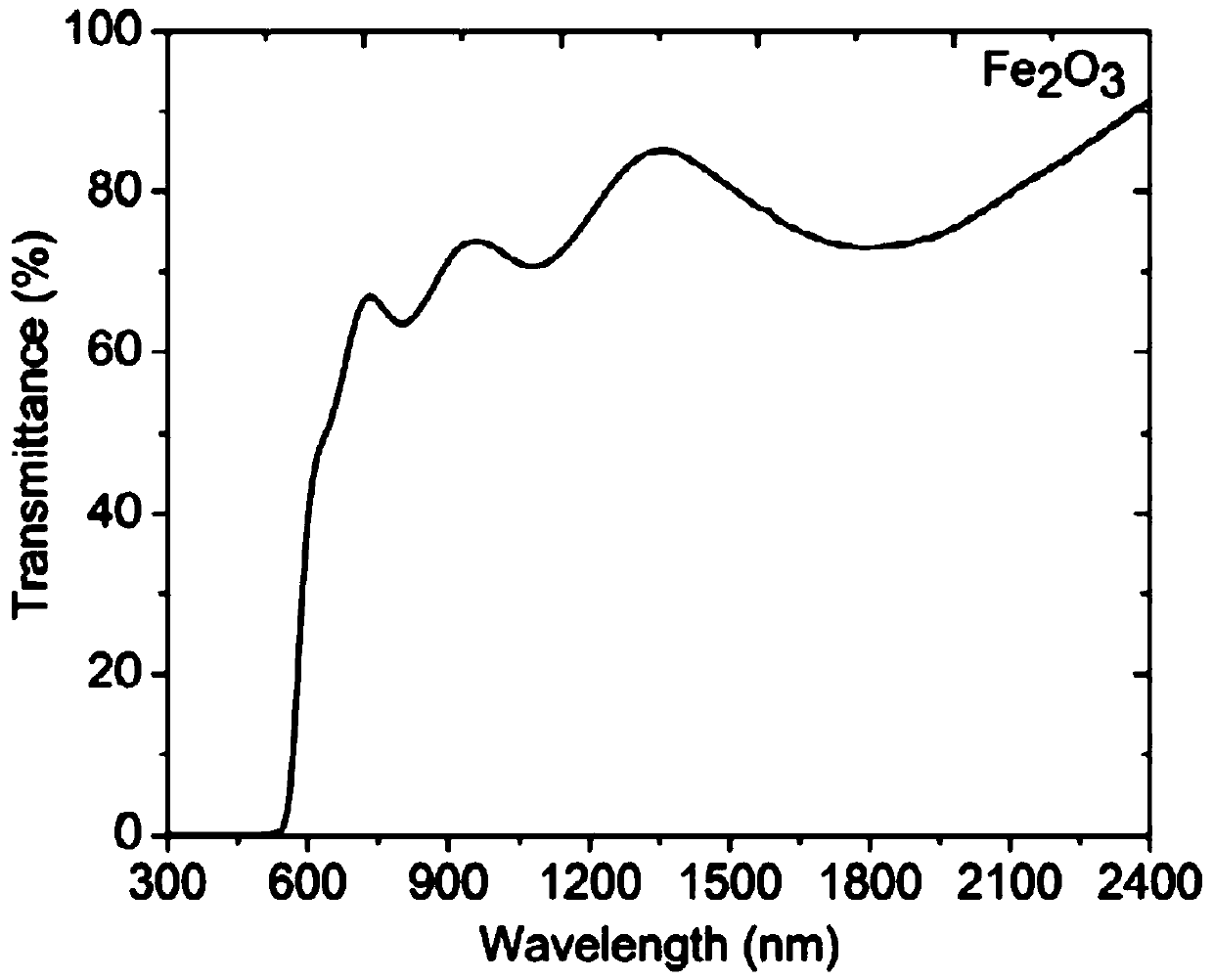

[0043] The composition of rust is Fe 2 o 3 , FeO, Fe 3 o 4 , the colors are reddish brown, black, black. as attached image 3 Shown, reddish-brown ...

Embodiment 2

[0049] Example 2 of the present invention takes the removal of blue acrylic resin paint on bricks as an example. The cleaning process of the laser cleaning machine is as follows: plug the laser cleaning machine into the power supply, turn on the key switch, click the laser emission switch on the indicator panel 21, and pick up the laser cleaning machine. Laser cleaning head 1 is aimed at the acrylic paint on the brick to be cleaned, adjust the distance of the laser cleaning head to the brick plane, the distance is about the focal length, the optical path of the cleaning head forms an angle of about 75° with the brick plane, press the cleaning head handle The laser launch button on 7 scans back and forth on the brick plane to clean the blue acrylic paint, and the laser can effectively remove the blue acrylic paint for cleaning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com