Preparation method of strongly-combined double-layer nanofiltration membrane

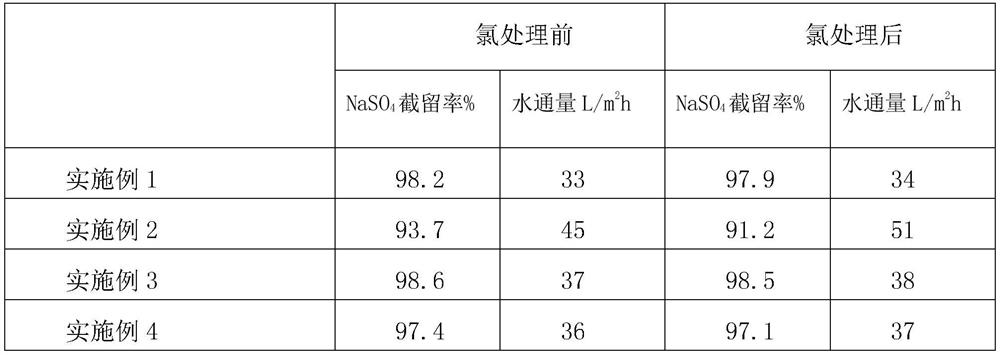

A nanofiltration membrane and double-layer technology is applied in the field of preparation of strong-bonded double-layered nanofiltration membranes, which can solve the problems of weak bonding force between the separation layer and the support layer, poor chlorine resistance of polyamide nanofiltration membranes, and shortened service life, etc. Achieving good development prospects, strong binding force and high water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing a strongly combined double-layer nanofiltration membrane, the specific steps are as follows:

[0023] 1) Preparation of casting solution: Add 20g of polyethersulfone, 5g of carboxyl-terminated SMA and 5g of polyethylene glycol-800 into 70g of DMAC organic solution, heat to 70°C, and stir until homogeneous;

[0024] 2) Vacuum static defoaming: keep the above-mentioned casting liquid in a heated state to evacuate, stop stirring and carry out defoaming treatment;

[0025] 3) Preparation of the base film: prepare the base film from the casting solution by phase inversion method, place it in deionized water for use;

[0026] 4) Preparation of a single-layer nanofiltration membrane: prepare a polyglycerin solution with a mass fraction of 10%, pour the solution on the surface of the base membrane, and obtain a single-layer polyester composite nanofiltration membrane after crosslinking for 2 hours;

[0027] 5) Preparation of double-layer nanofiltration m...

Embodiment 2

[0029] A method for preparing a strongly combined double-layer nanofiltration membrane, the specific steps are as follows:

[0030] 1) Preparation of casting solution: Add 15g of polysulfone, 5g of carboxyl-terminated SMA and 3g of polyvinylpyrrolidone K30 into 77g of DMAC organic solution, heat to 70°C, and stir until homogeneous;

[0031] 2) Vacuum static defoaming: keep the above-mentioned casting liquid in a heated state to evacuate, stop stirring and carry out defoaming treatment;

[0032] 3) Preparation of the base film: prepare the base film from the casting solution by phase inversion method, place it in deionized water for use;

[0033] 4) Preparation of composite nanofiltration membrane: prepare a polyglycerin solution with a mass fraction of 0.5%, pour the solution on the surface of the basement membrane, and cross-link for 5 hours to obtain a single-layer composite nanofiltration membrane.

[0034] 5) Preparation of a double-layer nanofiltration membrane: Prepare ...

Embodiment 3

[0036] A method for preparing a strongly combined double-layer nanofiltration membrane, the specific steps are as follows:

[0037] 1) Preparation of casting solution: Add 20g of polyvinylidene fluoride, 5g of carboxyl-terminated SMA and 5g of polyvinylpyrrolidone into 70g of DMAC organic solution, heat to 80°C, and stir until homogeneous;

[0038] 2) Vacuum static defoaming: keep the above-mentioned casting liquid in a heated state to evacuate, stop stirring and carry out defoaming treatment;

[0039] 3) Preparation of the base film: prepare the base film from the casting solution by phase inversion method, place it in deionized water for use;

[0040] 4) Preparation of composite nanofiltration membrane: a polyglycerol solution with a mass fraction of 3% was prepared, poured the solution on the surface of the basement membrane, and crosslinked for 3 hours to obtain a composite nanofiltration membrane.

[0041] 5) Preparation of a double-layer nanofiltration membrane: Prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com