Lithium ion battery positive electrode material uniformly coated with MOF (Metal Organic Framework) and preparation method of lithium ion battery positive electrode material

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of complex preparation process, high cost, and difficulty in forming a uniform coating layer, and achieve high specific capacity, good Rate performance, the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

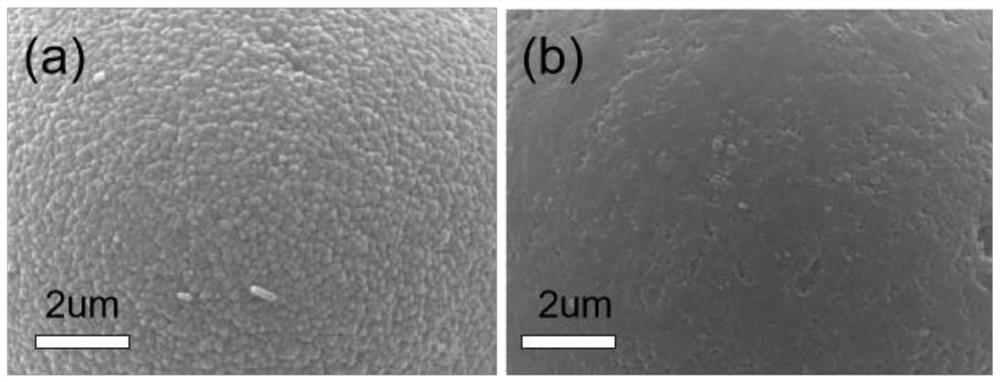

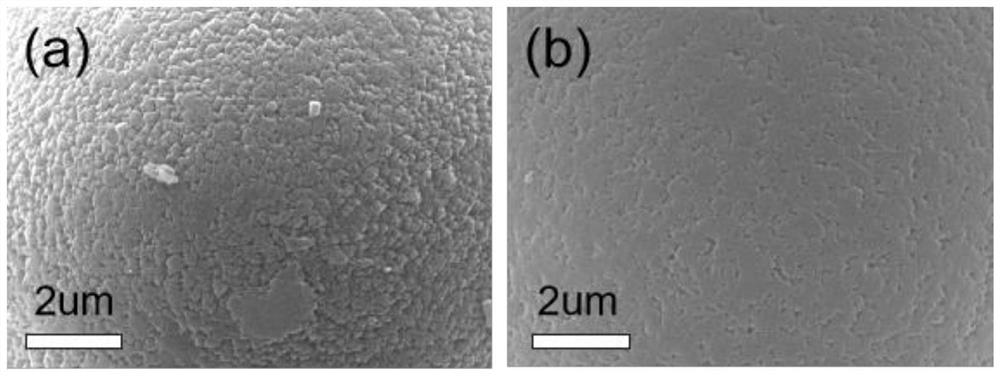

[0029] A method for preparing a positive electrode material of a lithium-ion battery coated with MOF uniformly provided by an embodiment of the present invention, such as figure 1 shown, including the following steps:

[0030] (1) Add 2,5-dihydroxyterephthalic acid or its derivatives into an organic solvent and stir for 10-20 minutes to obtain a solution of 2,5-dihydroxyterephthalic acid, namely solution A;

[0031] (2) Add the lithium-ion battery positive electrode particles into the solution A under stirring, and stir at room temperature for 4h to 8h to obtain the mixed solution B; wherein the hydroxyl group in 2,5-dihydroxyterephthalic acid and the lithium-ion battery positive electrode The residual alkali on the particle is combined, and the 2,5-dihydroxyterephthalic acid is coated on the surface of the positive electrode particle of the lithium-ion battery through hydrogen bonding;

[0032] (3) Add the metal salt to the mixed solution B under stirring, stir at room tempe...

Embodiment 1

[0042] A method for preparing a positive electrode material for a lithium-ion battery with uniformly coated MOF, comprising the following steps:

[0043] (1) Add 25mL of N,N-dimethylformamide into a 50mL beaker, add 10.4mg of 2,5-dihydroxyterephthalic acid under the condition of stirring speed of 500r / min, and make it fully Dissolving to obtain solution A of 2,5-dihydroxyterephthalic acid;

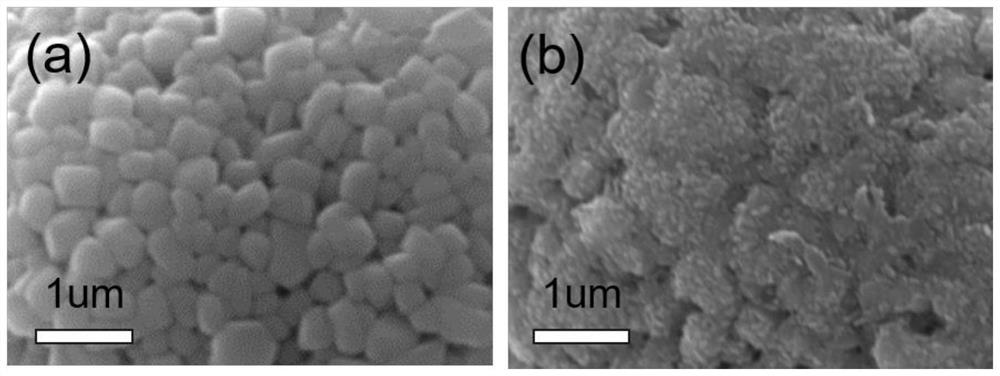

[0044] (2) Under mechanical stirring at 500r / min, slowly add 0.6g of lithium-rich manganese-based cathode material (Li 1.2 mn 0.54 co 0.13 Ni 0.13 o 2 ) to obtain a mixed solution B of 2,5-dihydroxyterephthalic acid coated lithium-rich manganese-based positive electrode material;

[0045] (3) Slowly add 10.6 mg of magnesium acetate tetrahydrate to the mixed solution B obtained in step (2) under mechanical stirring at 500 r / min to obtain a mixed solution C of Mg-MOF coated lithium-rich manganese-based positive electrode material;

[0046] (4) Stir the mixed solution C at 25°C for 15h;...

Embodiment 2

[0050] A method for preparing a positive electrode material for a lithium-ion battery with uniformly coated MOF, comprising the following steps:

[0051] (1) Add 25mL of N,N-dimethylformamide into a 50mL beaker, add 6.3mg of 2,5-dihydroxyterephthalic acid at a stirring speed of 500r / min, and dissolve it fully , to obtain 2,5-dihydroxyterephthalic acid solution A;

[0052] (2) Under the mechanical stirring of 500r / min, slowly add 1.2g lithium-rich manganese-based cathode material (Li 1.2 mn 0.54 co 0.13 Ni 0.13 o 2 ) to obtain a mixed solution B of 2,5-dihydroxyterephthalic acid coated lithium-rich manganese-based positive electrode material;

[0053] (3) Under mechanical stirring at 500r / min, slowly add 6.7mg of zirconium chloride to the mixed solution B obtained in step (2), to obtain a mixed solution C of Zr-MOF coated lithium-rich manganese-based positive electrode material;

[0054] (4) Stir the mixed solution C at 40°C for 8h;

[0055] (5) Suction filtration of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com