Ultrasonic phased array defect imaging method based on F-DMAS and pseudo color

A F-DMAS, ultrasonic phased array technology, applied in the direction of material analysis, image enhancement, image analysis, etc. using sonic/ultrasonic/infrasonic waves, can solve problems such as dependence, difficulty in identifying defects in false color images, and achieve the advantage of detection capabilities , the advantage of expression effect, the effect of improving expression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

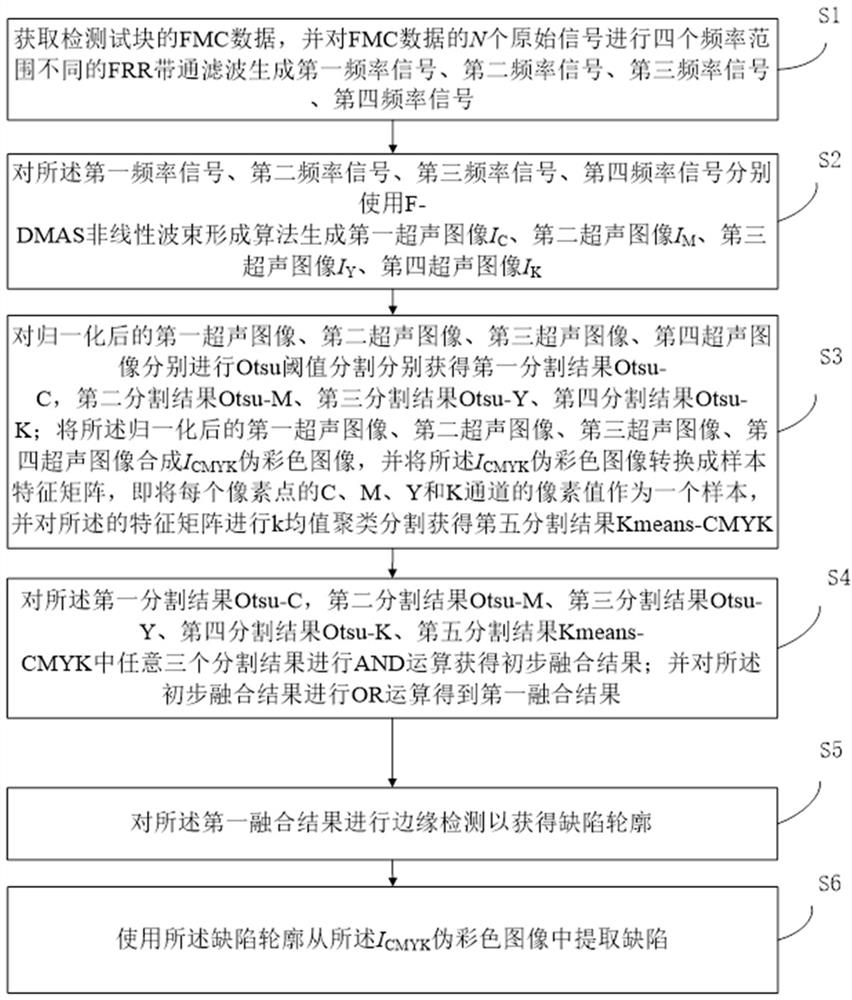

[0048] refer to figure 1 , the present embodiment discloses an ultrasonic phased array defect imaging method based on F-DMAS and pseudo-color, which includes the following steps:

[0049] S1, obtain the FMC data of the detection test block, and perform four FRR bandpass filters with different frequency ranges on the N original signals of the FMC data to generate a first frequency signal, a second frequency signal, a third frequency signal, and a fourth frequency signal ;

[0050] The first frequency signal is a low frequency signal, the second frequency signal is an intermediate frequency signal, the third frequency signal is a high frequency signal, and the fourth frequency signal is a full frequency signal. Without loss of generality, the first frequency is cyan, and the second frequency is magenta. Red, the third frequency is yellow, and the fourth frequency is black.

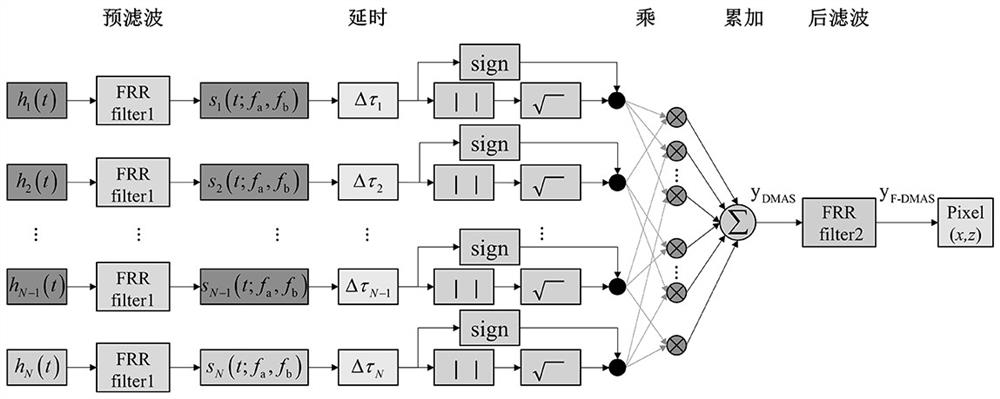

[0051] Schematic diagram of the F-DMAS imaging algorithm as shown in figure 2 shown. Suppose the pha...

Embodiment 2

[0095] refer to Figure 10 , this embodiment discloses a strong attenuation material defect detection device based on F-DMAS and pseudo-color ultrasonic phased array defect imaging detection device, which includes the following units:

[0096] The band-pass filter extraction unit is used to detect the FMC data of the test block, and perform four FRR band-pass filters with different frequency ranges on the N original signals of the FMC data to generate a first frequency signal, a second frequency signal, and a first frequency signal. Three frequency signals, fourth frequency signals; filter delay multiplication and accumulation nonlinear beamforming ultrasonic imaging unit, used to generate first ultrasonic waves for the first frequency signal, second frequency signal, third frequency signal, and fourth frequency signal respectively image I C , second ultrasound image I M , the third ultrasound image I Y , the fourth ultrasound image I K ;

[0097] Segmentation unit, f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com