Method for detecting chlorine content in crude benzene

A chlorine content, crude benzene technology, applied in the direction of measuring devices, chemical method analysis, chemical analysis by titration, etc., can solve the problems of high cost of waste liquid treatment, complicated analysis and detection process, large investment in drugs, etc., and achieve the expansion of concentration Increased detection range, improved analysis efficiency, and time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1-5

[0031] Crude benzene mock sample

Embodiment 1-5

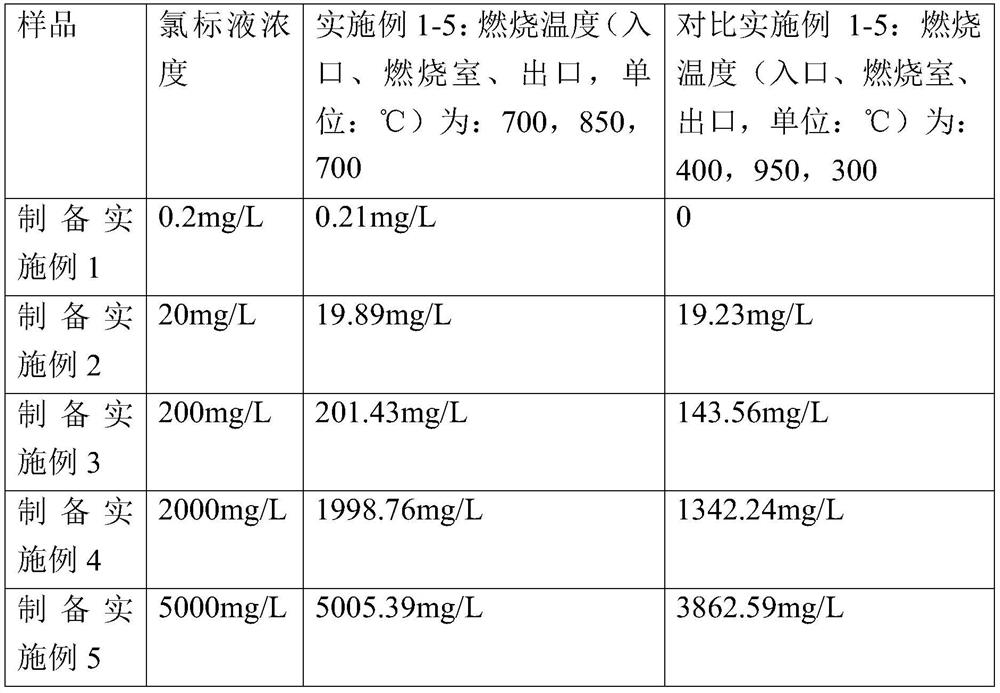

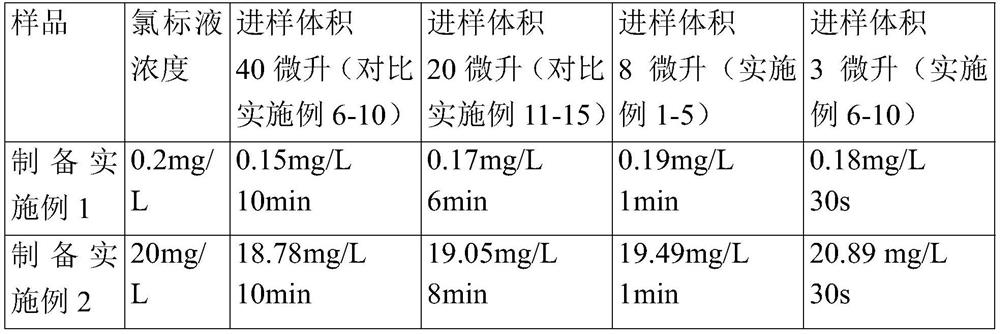

[0035] The crude benzene simulated samples whose chlorine content is respectively 0.2mg / L, 20mg / L, 200mg / L, 2000mg / L, and 5000mg / L in Preparation Examples 1-5 are introduced into the injector respectively, and the injection volume is 8 μ L. Using nitrogen as the carrier gas, mix the crude benzene simulated sample, oxygen and carrier gas, so that the crude benzene simulated sample can be fully burned in the combustion chamber. The temperature of the combustion chamber is: the inlet temperature of the combustion chamber, the cracking temperature in the combustion chamber, the The outlet temperatures are set to 700°C, 850°C and 700°C respectively, and the chlorine element in the sample is converted into hydrogen chloride, which is absorbed in the titration cell.

[0036] A 70% aqueous solution of acetic acid (volume fraction, the same below) was used as the electrolyte. In the titration cell, the combustion product and the titrant Ag in the titration cell + The following reactio...

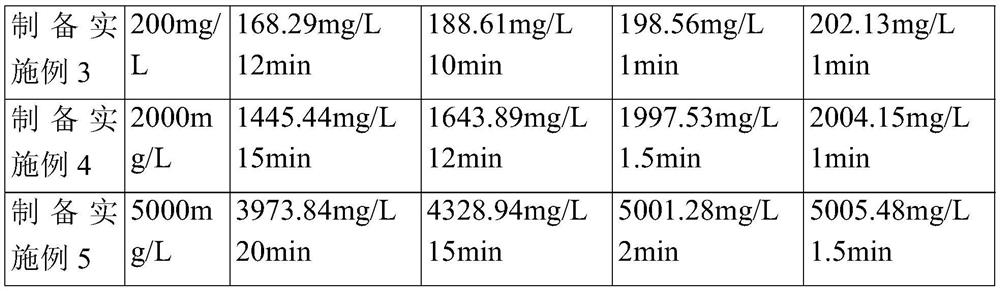

Embodiment 6-10

[0044] Experiments were performed in the same manner as in Examples 1-5 to carry out Examples 6-10, except that the injection volume was changed from 8 μL to 3 μL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com