Perpendicular crossing type mine return air heating fresh air heat exchanger and heat exchange method thereof

A technology of fresh air heat exchanger and mine return air, which is applied in the direction of indirect heat exchanger, heat exchanger type, mine/tunnel ventilation, etc., to achieve the effect of improving heat transfer coefficient, improving heat transfer coefficient and reducing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

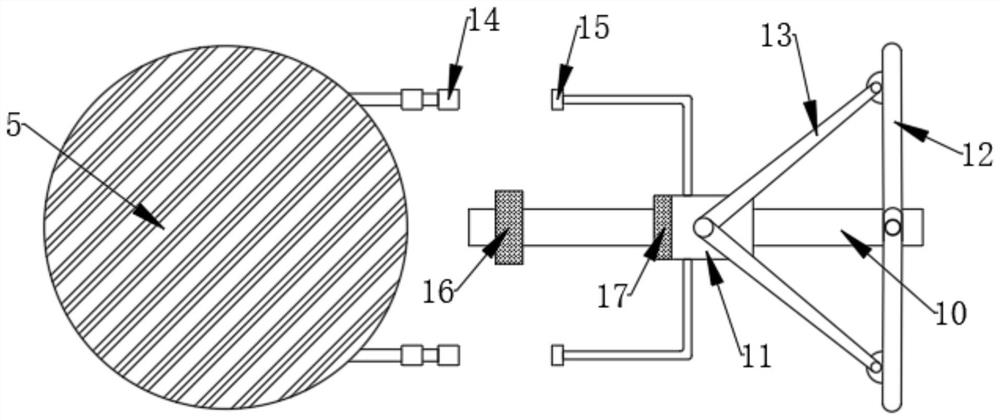

[0045] see Figure 1-8 , a vertical cross mine return air heating fresh air heat exchanger, see figure 1 , including a heat exchanger shell 1, the upper and lower ends of the heat exchanger shell 1 are respectively connected with a return air inlet pipe 2 and a return air outlet pipe 3, and the bottom of the heat exchanger shell 1 located around the return air outlet pipe 3 is inclined, To facilitate the flow of condensed water, the inner wall of the heat exchanger shell 1 is fixedly connected with two heat shields 4, and there are multiple sets of heat exchange tubes 5 fixedly connected between the two heat shields 4, please refer to Figure 5 , the number of heat exchange tubes 5 is five groups, and each group of heat exchange tubes 5 has an independent ventilation and heat exchange function. The heat exchange area is to enhance the convective heat transfer coefficient of the fresh air side. The shape of the heat exchange tube 5 is curved to increase the heat exchange effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com