Interlocking type locknut

A technology of locking nuts and locking nuts, applied in the directions of nuts, screws, bolts, etc., can solve the problem of loosening of bolts and nut connectors, and achieve the effect of preventing thermal expansion and elongation and achieving good effect of reuse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

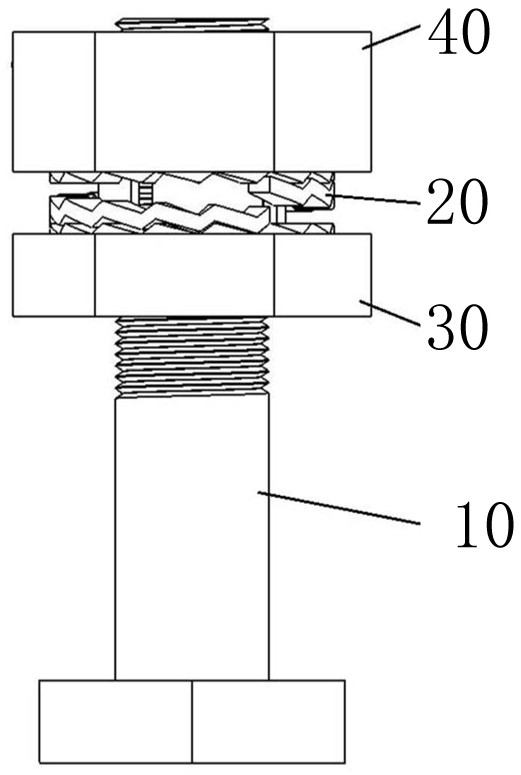

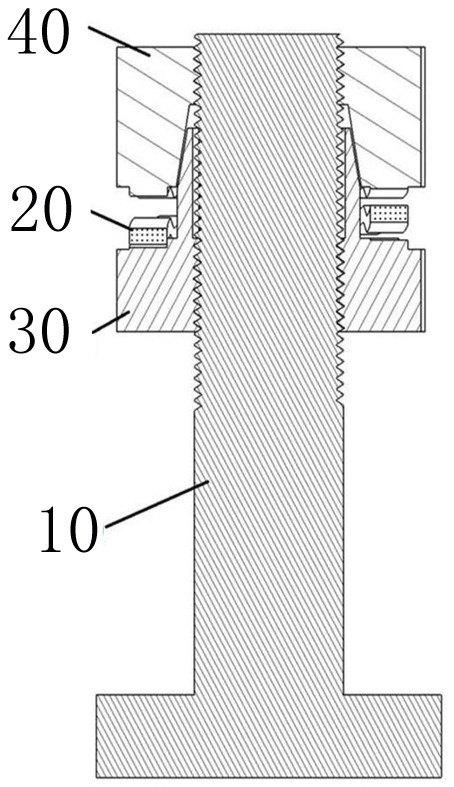

[0026] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0027] It should be noted:

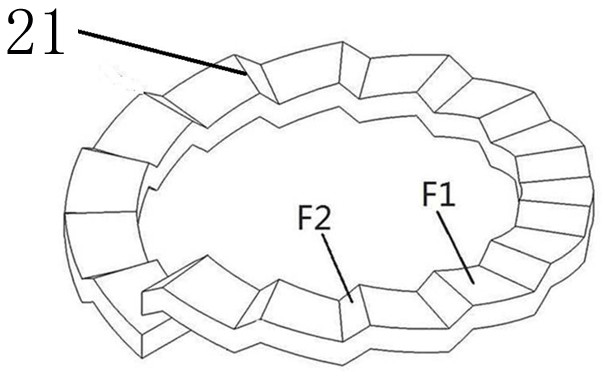

[0028] The critical angle θ refers to the minimum slope or angle required for the anti-loosening surfaces of the anti-loosening teeth to be unable to form relative sliding due to mutual resistance when the loosening occurs due to vibration;

[0029] The uphill tangent direction refers to the direction from the root of the anti-loosening tooth to the top of the tooth;

[0030] The slope refers to the angle between the uphill tangent of the point on the guide surface or the anti-loosening surface and the vertical plane of the central axis;

[0031] The helix angle of the elastic anti-loosening ring is greater than the lead angle of the same-handed thread, and the lead angle and helix angle have the same regulations as the terms of the thread in the machine.

[0032] The present invention as Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com