Preparation method of blood peptide chelate

A chelate and blood peptide technology, which is applied in the field of blood peptide chelate preparation, can solve the problems of limiting the application of blood peptide and its chelate, uncontrollable molecular weight, and low chelation rate, so as to improve the utilization value, The preparation method is simple, and the effect of improving the chelation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

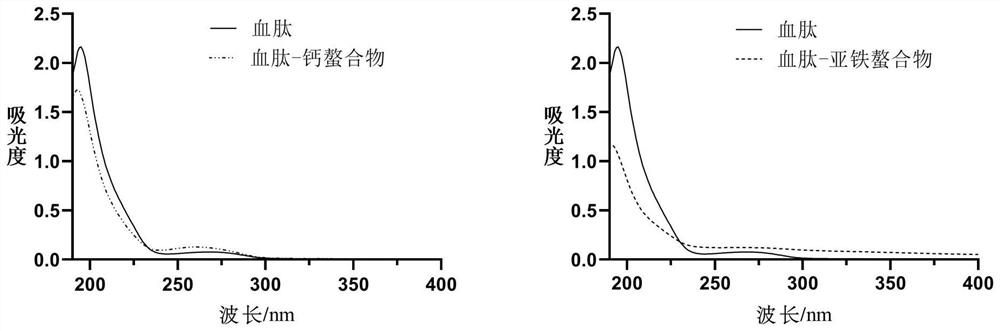

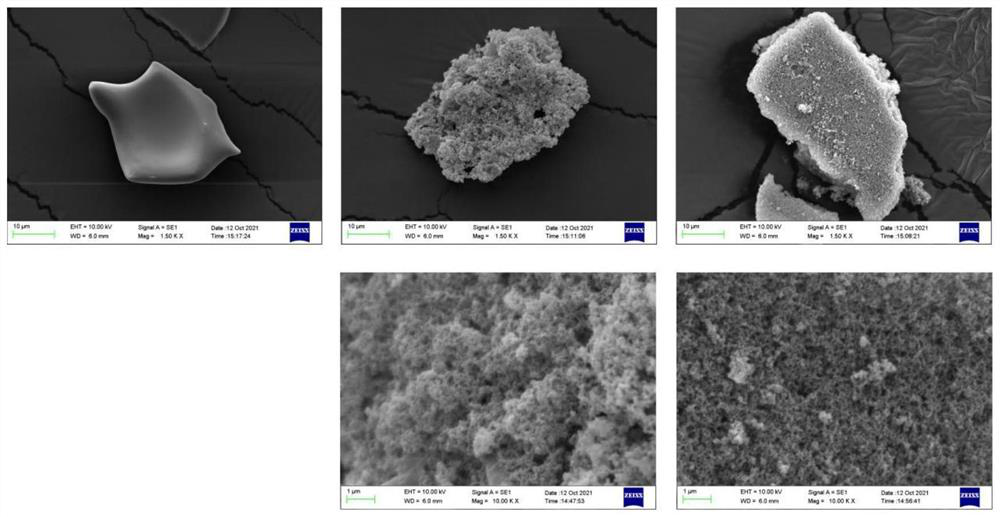

[0026] Example 1: 100 kg of fresh pig blood was anticoagulated and impurity removed, then centrifuged at 3000 g for 15 min to collect precipitated blood cells. Add water and stir evenly to adjust the blood cell concentration to about 20% to swell the cells, and at the same time carry out homogenization treatment for 40 minutes; centrifuge at 3000g for 10 minutes, and collect the supernatant hemoglobin. Add 4‰ alkaline protease, 3‰ neutral protease, and 3‰ compound flavor protease to the hemoglobin solution for enzymolysis. The enzymolysis time is 5 hours. After the enzymolysis, the temperature is raised to 95°C and kept for 15 minutes to inactivate the enzyme, and the enzymolysis is obtained. Centrifuge the enzymolysis solution with a 4000g tube centrifuge for 10 minutes, then filter and purify the supernatant with a 20nm nanofiltration membrane, and ultrasonically treat the nanofiltration solution for 5 minutes. The temperature is 55°C, the frequency is 20kHz, and the power i...

Embodiment 2

[0027] Example 2: Take 100 kg of fresh anticoagulated chicken blood, centrifuge at 3000g for 15min, add 5 times the volume of water to the precipitate and stir for 40min, centrifuge at 3000g for 10min to obtain a hemoglobin solution, add 4‰ alkaline protease and 3‰ neutral protease and 3‰ compound flavor protease for enzymolysis, the enzymolysis time is 6 hours, after the enzymolysis, the temperature is raised to 95°C and kept for 15 minutes to inactivate the enzyme, and the enzymolysis solution is obtained, and the enzymolysis solution is centrifuged in a 4000g tubular centrifuge for 10 minutes. The supernatant was filtered and purified with a 20nm nanofiltration membrane, and then sonicated for 15 minutes. The working conditions of the sonication were 10-20s working time, 5-10s resting time, 55°C ultrasonic temperature, 20kHz frequency, and 200W power. Then adjust its pH to 4.5 and add 8% FeSO 4 .7H 2 O, stirring at 40 rpm for 40 min at 37°C to obtain a chelating solution, ...

Embodiment example 3

[0028] Implementation Case 3: The procedure is the same as in Example 2. After extracting hemoglobin from fresh chicken blood, add 4‰ alkaline protease, 3‰ neutral protease and 3‰ compound flavor protease for enzymolysis. The enzymolysis time is 5 hours. Rise to 95°C and keep it for 15 minutes to inactivate the enzyme to obtain the enzymatic hydrolysis solution. Centrifuge the enzymatic hydrolysis solution with a 4000g tube centrifuge for 10 minutes. The supernatant is filtered and purified with a 20nm nanofiltration membrane and then ultrasonicated for 10 minutes. The ultrasonic working condition is working The time is 10-20 s, the rest time is 5-10 s, the ultrasonic temperature is 55°C, the frequency is 20kHz, and the power is 200W. Then adjust its pH to 4 and add 15% ZnSO in the resulting nanofiltrate 4 .7H 2 O, stirring at a speed of 40 rpm for 60 min at 30° C. to obtain a chelating solution, which was concentrated and then spray-dried to obtain the animal blood peptide c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com