Ore composition with infrared ray release and degradation functions and preparation method thereof

An infrared and composition technology, applied in the field of ore preparation, can solve problems such as incompleteness, achieve the effects of scientific proportioning, simple and easy-to-control process, and ensure food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment provides a method for preparing an ore composition with functions of releasing infrared rays and degrading, comprising the following steps:

[0024] (1) 28g malachite, 16g garnet, 18g agate, 24g tourmaline, 21g quartz stone, 24g medical stone, 20g ocher, 16g gabbro, 23g meteorite, 28g diamond, 18g crystal, 20g nanhongite, 26g tourmaline, 24g obsidian, 20g jade, 20g olivine, 16g granite, 13g stone bone, 11g spodumene, 10g aquamarine, 16g basalt, 14g fluorite, 16g feldspar, 14g sodalite, 18g of volcanic rock and 6g of tiger's eye were mixed and pulverized to an average particle size of 80 mesh, and mixed for 20min at 40r / min to obtain the ore mixture;

[0025] (2) adding water to the ore mixture and stirring it evenly to form a circular shape with holes in the middle to obtain a shaped ore mixture;

[0026] (3) heating and firing the shaped ore mixture at 1350° C. for 22 hours, and then obtaining the ore composition with functions of releasing infrared ra...

Embodiment 2

[0028] This embodiment provides a method for preparing an ore composition with functions of releasing infrared rays and degrading, comprising the following steps:

[0029] (1) 32g malachite, 20g garnet, 22g agate, 28g tourmaline, 25g quartz stone, 28g medical stone, 24g ochre, 20g gabbro, 27g meteorite, 32g diamond, 22g crystal, 24g nanhong stone, 30g tourmaline, 28g obsidian, 24g jade, 24g olivine, 20g granite, 17g stone bone, 15g spodumene, 14g aquamarine, 20g basalt, 18g fluorite, 20g feldspar, 18g sodalite, 22g of volcanic rock and 10g of tiger's eye were mixed and pulverized to an average particle size of 150 mesh, and mixed for 30min at 60r / min to obtain the ore mixture;

[0030] (2) adding water to the ore mixture and stirring it evenly to form a circular shape with holes in the middle to obtain a shaped ore mixture;

[0031] (3) The shaped ore mixture is heated and fired at 1400° C. for 26 hours, and the ore composition with functions of releasing infrared rays and de...

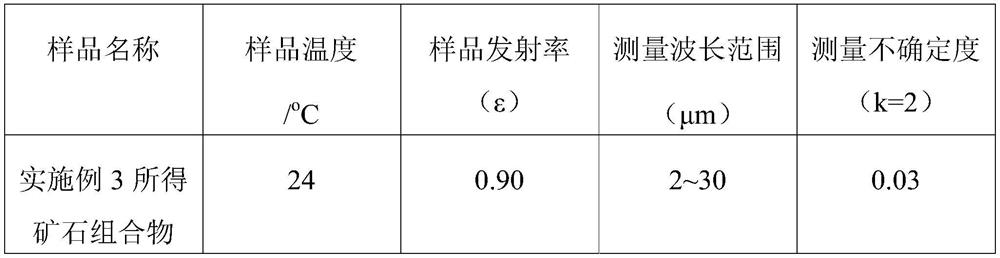

Embodiment 3

[0033] This embodiment provides a method for preparing an ore composition with functions of releasing infrared rays and degrading, comprising the following steps:

[0034] (1) 30g malachite, 18g garnet, 20g agate, 26g tourmaline, 23g quartz stone, 26g medical stone, 22g ochre, 18g gabbro, 25g meteorite, 30g diamond, 20g crystal, 22g nanhong stone, 28g tourmaline, 26g obsidian, 22g jade, 22g olivine, 18g granite, 15g stone bone, 13g spodumene, 12g aquamarine, 18g basalt, 16g fluorite, 18g feldspar, 16g sodalite, 20g of volcanic rock and 8g of tiger's eye were mixed and pulverized to an average particle size of 110 mesh, and mixed for 25min at 50r / min to obtain the ore mixture;

[0035] (2) adding water to the ore mixture and stirring it evenly to form a circular shape with holes in the middle to obtain a shaped ore mixture;

[0036] (3) heating and firing the shaped ore mixture at 1350° C. for 24 hours, and then obtaining the ore composition with functions of releasing infrare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com