Container conveying system capable of achieving unmanned unloading

A conveying system and container technology, applied in the field of container conveying system, can solve the problems of cargo squeeze vibration, cargo damage, damage, etc., and achieve the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention are described in detail below; the embodiments described below are exemplary, are only used to explain the present invention, and cannot be interpreted as limitations of the present invention; if no specific techniques or conditions are indicated in the embodiments, according to the technical field The techniques or conditions described in the literature or in accordance with the product instructions.

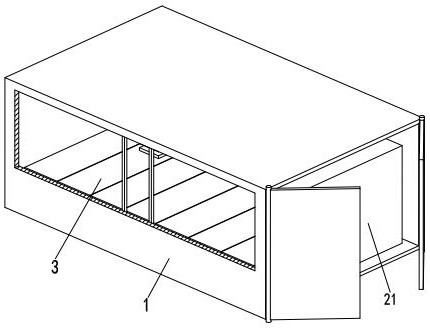

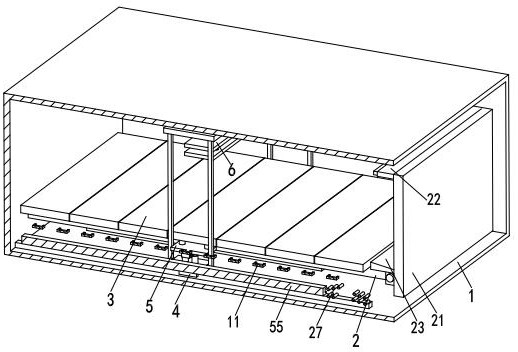

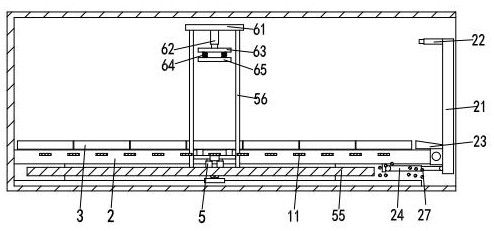

[0035] refer to Figure 1 to Figure 3 , Figure 8 , a container conveying system that can be unmanned unloading, including a container body 1, a support base 2, a mounting plate 3, an electric slider 4 and a jacking mechanism 5, the container body 1 is a box structure, and the container body 1 The right end is provided with an opening and closing door, and the lower side wall of the container body 1 is equipped with a support base 2, and the upper side of the support base 2 is evenly provided with a mounting plate 3 along its len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com