Novel kitchen waste treatment system and treatment process

A food waste and treatment system technology, applied in food processing, transportation and packaging, chemical instruments and methods, etc., can solve the problems of many sets of supporting equipment, complicated treatment process, hidden dangers of germ safety, etc., and achieve low equipment cost, separate The effect of simple process and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 provides a new type of food waste treatment system and treatment process. details as follows.

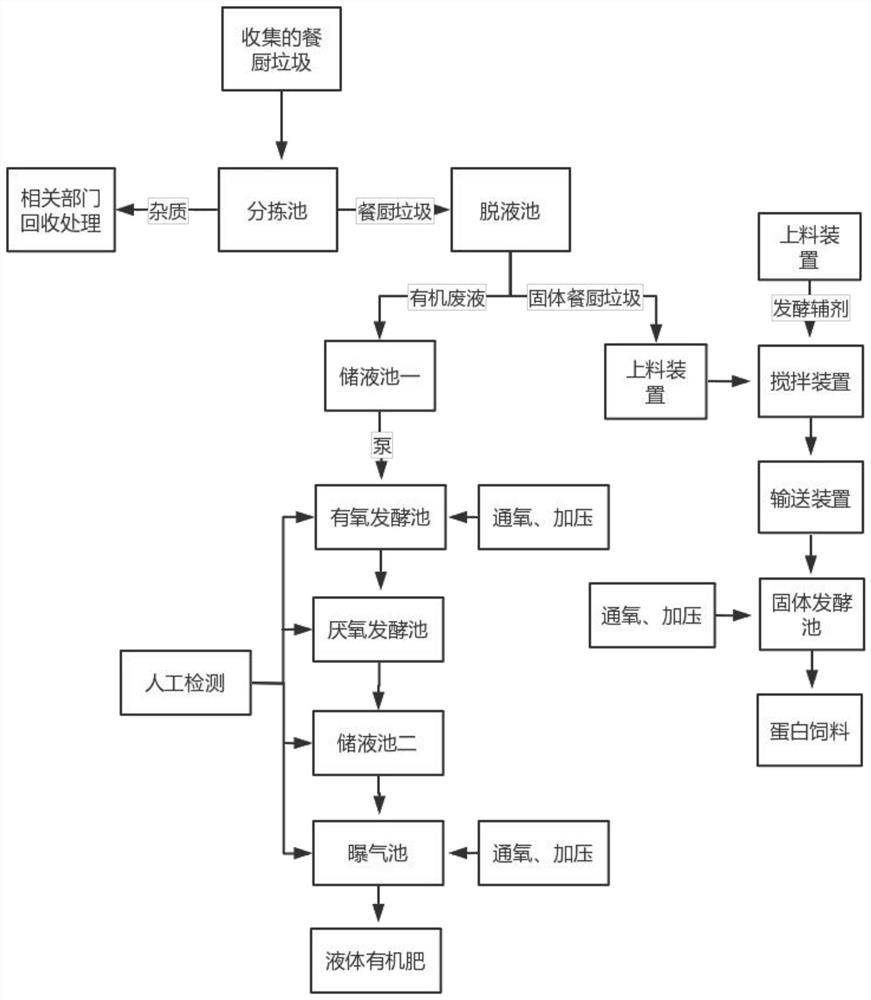

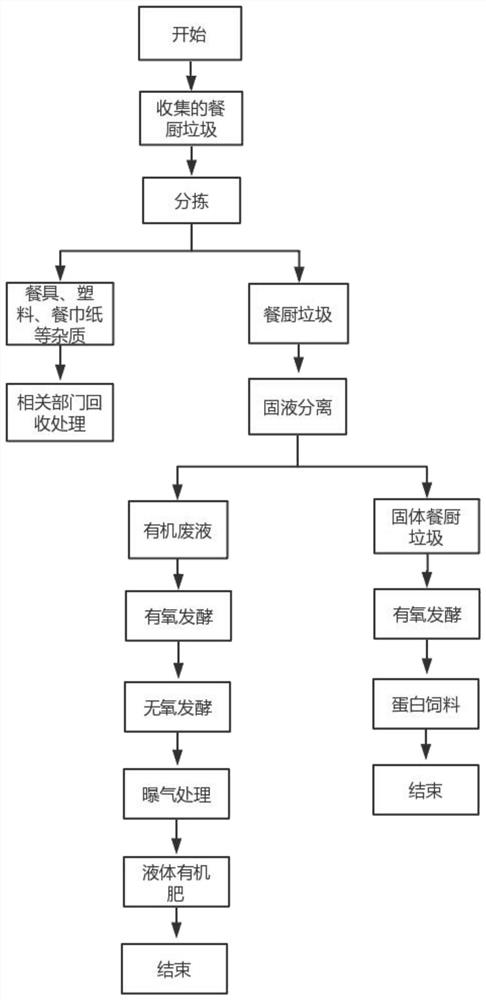

[0030] see figure 1 , Embodiment 1 provides a new type of food waste treatment system, the treatment system includes a sorting tank, a dehydration tank, a liquid storage tank, a feeding device, a stirring device, a conveying device, a solid fermentation tank and a liquid fermentation tank. pool;

[0031] The sorting tank is used to separate tableware, plastics, napkins and kitchen waste; the deliquoring tank is used to separate the food waste into solid and liquid to obtain solid kitchen waste and organic waste liquid; the stirring device is used to stir mixing solid food waste and fermentation auxiliary materials; the solid fermentation tank is used to ferment solid food waste; the liquid fermentation tank is used to ferment organic waste liquid;

[0032]The sorting tank is connected to the deliquoring tank; the organic waste liquid in the deliquoring tank is...

Embodiment 2

[0040] see figure 1 , embodiment 2 is an improvement on the basis of embodiment 1. In embodiment 2, a water filter device and a drainage pipe are arranged in the sorting tank, and the water filter device uses high-temperature circulating water to preheat the food waste in the sorting tank. Melting solid grease and diluting the oil and salt content of kitchen waste; the filtered water is finally transported to the liquid storage tank one through the drainage pipeline; a slope connection is provided between the sorting tank and the deliquoring tank, so The water filtering device transports the sorted solid food waste to the deliquoring tank through the slope. A multi-layer extruding device is provided in the deliquoring pool, and the multi-layer extruding device is composed of horizontally movable extruding plates of different specifications. There is a nozzle, and the nozzle sprays water to wash the surface of the extruded plate, and the extruded plate is provided with a throu...

Embodiment 3

[0047] see figure 1 , embodiment 3 is the improvement that is carried out on the basis of embodiment 2, and liquid fermentation tank comprises aerobic fermentation tank, anaerobic fermentation tank, liquid storage tank two and aeration tank among the embodiment 3, described aerobic fermentation tank, The anaerobic fermentation tank, liquid storage tank 2 and aeration tank are airtight structures and are all equipped with manual detection channels. The aeration plate, pressurization device and oxygen ventilation device at the bottom of the aerobic fermentation tank; the organic waste liquid passes through the pipeline From the deliquification tank to the liquid storage tank 1, the organic waste liquid in the liquid storage tank 1 flows from the liquid storage tank 1 into the aerobic fermentation tank for aerobic fermentation through the pipeline, and the organic waste liquid after aerobic fermentation flows into the anaerobic fermentation tank through the pipeline The fermentat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com