Crushed hair recovery equipment for brush processing

A technology for recycling equipment and brushes, which is applied in the field of broken hair recovery equipment for brush processing, can solve the problems affecting the normal recovery of broken hair and the impact of brush processing efficiency, and achieves the effects of good linkage, improved processing efficiency and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

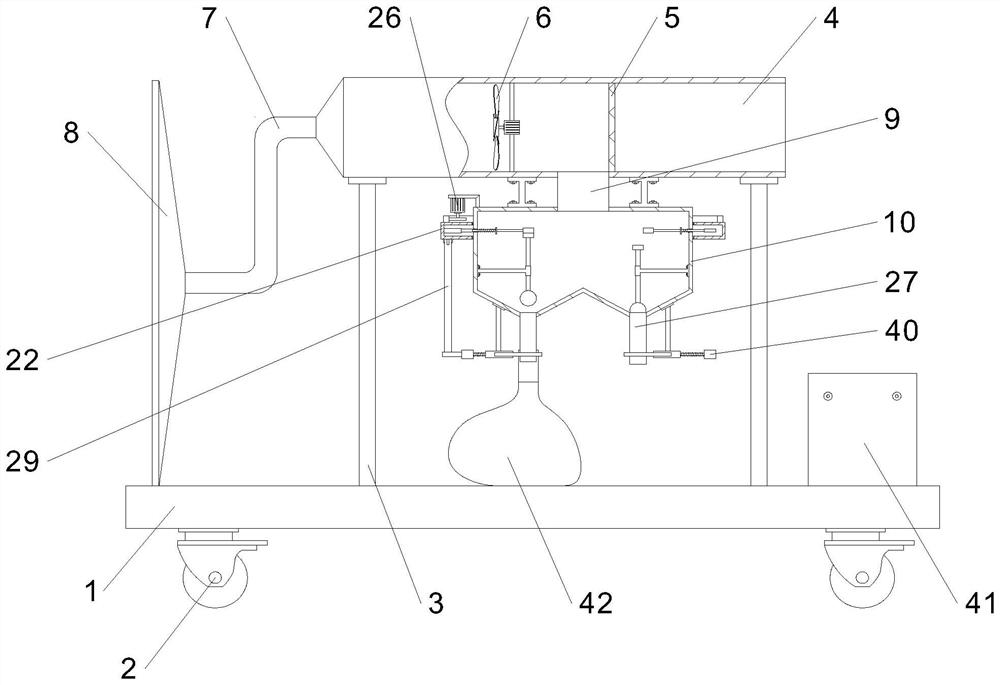

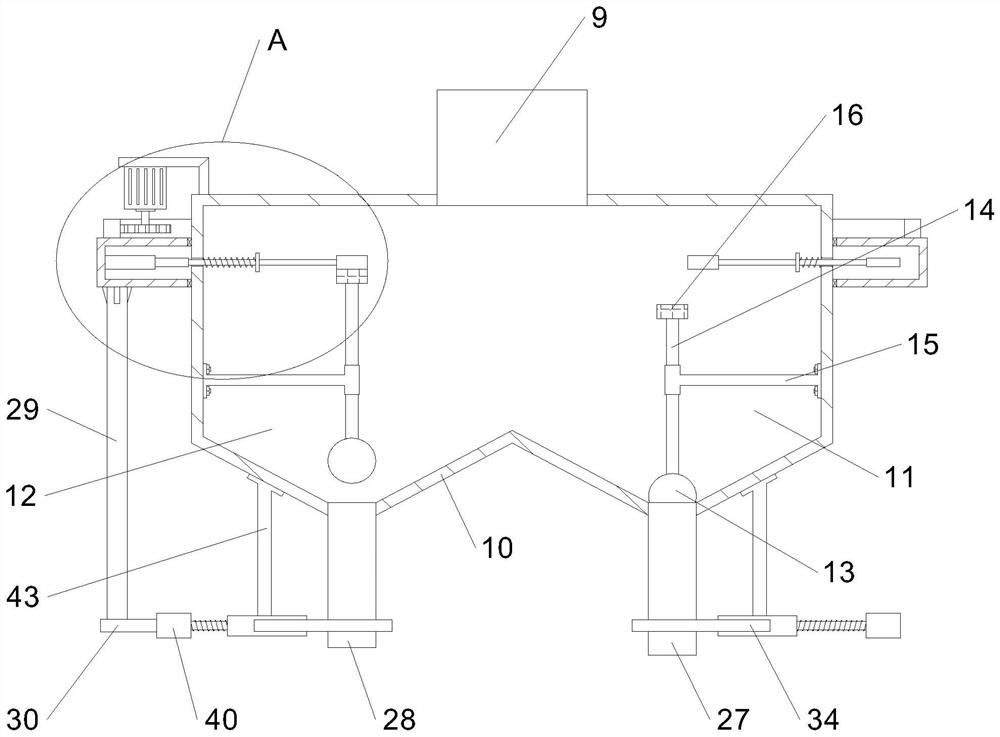

[0030] In this embodiment, as shown in Figures 1-6, a broken hair recovery device for brush processing includes a bottom plate 1, and a roller 2 is installed at the bottom of the bottom plate 1. The top of the bottom plate 1 is fixed with a cylinder 4 through the legs 3, the inner wall of the cylinder 4 is fixed with a filter plate 5, and one end of the cylinder 4 is connected with a suction hood 8 through a hose 7, and the suction hood 8 is fixed with the bottom plate 1 A fan 6 is installed on the inner wall of the cylinder 4 corresponding to the position between the hose 7 and the filter plate 5, and the bottom wall of the cylinder 4 is located on one side of the filter plate 5 and is connected with a silo 10 through a drop pipe 9. The silo 10 Divided into cavity one 11 and cavity two 12, the bottom wall of cavity one 11 is connected with connecting tube one 27, the bottom wall of cavity two 12 is connected with connecting tube two 28, cavity one 11 and cavity two 12 are conn...

Embodiment 2

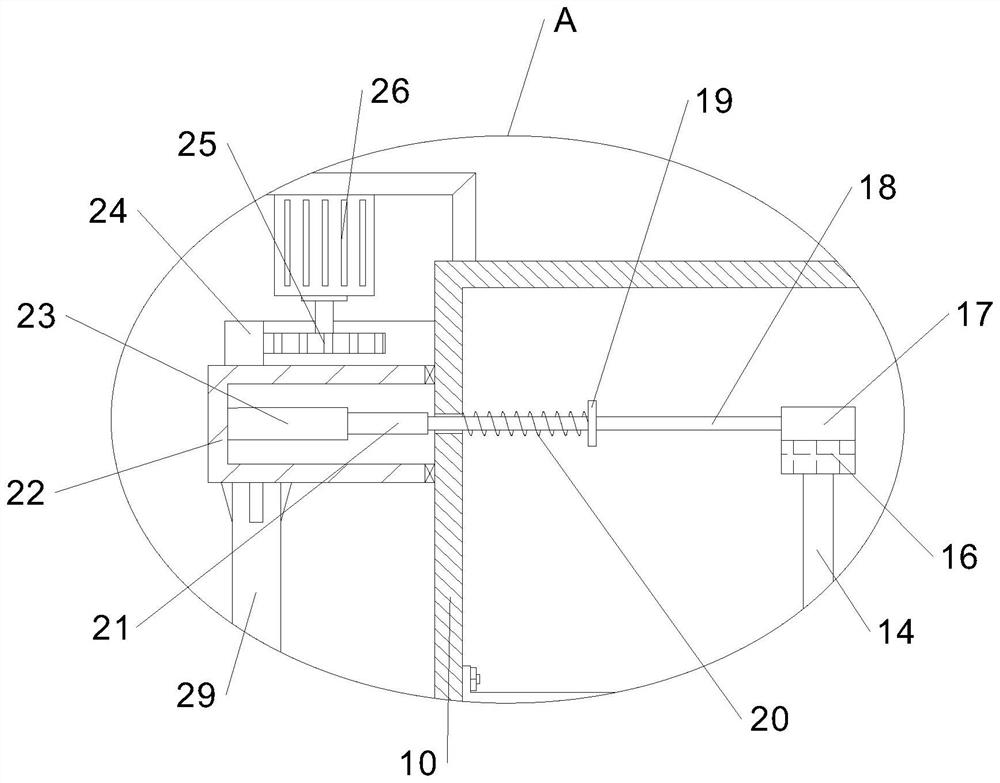

[0033] On the basis of Embodiment 1, the bottom ends of cavity one 11 and cavity two 12 are provided with a clamping mechanism for clamping the plastic bag 42 through the vertical rod 43, and the rotating shell 22 is correspondingly connected with the two clamping mechanisms. The clamping mechanism includes a housing 31 fixed on the bottom of the vertical rod 43. The front and rear side walls of the housing 31 are connected with push rods 32 slidingly through them. The outer ends of the two push rods 32 are fixed with clamp rods 34. Bar 32 corresponds to the position between the housing 31 and the clamping rod 34 and is sleeved with a spring 2 33, and the inner ends of the two clamping rods 34 are fixed with clamping plates 35, and the inner ends of the clamping plates 35 are fixed with rubber pads. The positions of the two push rods 32 on the inner wall of the housing 31 are equipped with fixed pulleys 36, and the inner ends of the two push rods 32 are fixed with stay ropes 37...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com