Sealed mixing equipment capable of carrying out secondary feeding

A technology of mixing equipment and secondary feeding, which is applied in mixers, mixers, and dissolving directions with rotary stirring devices, can solve the problems of inaccurate control and adjustment, large air pressure adjustment range, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

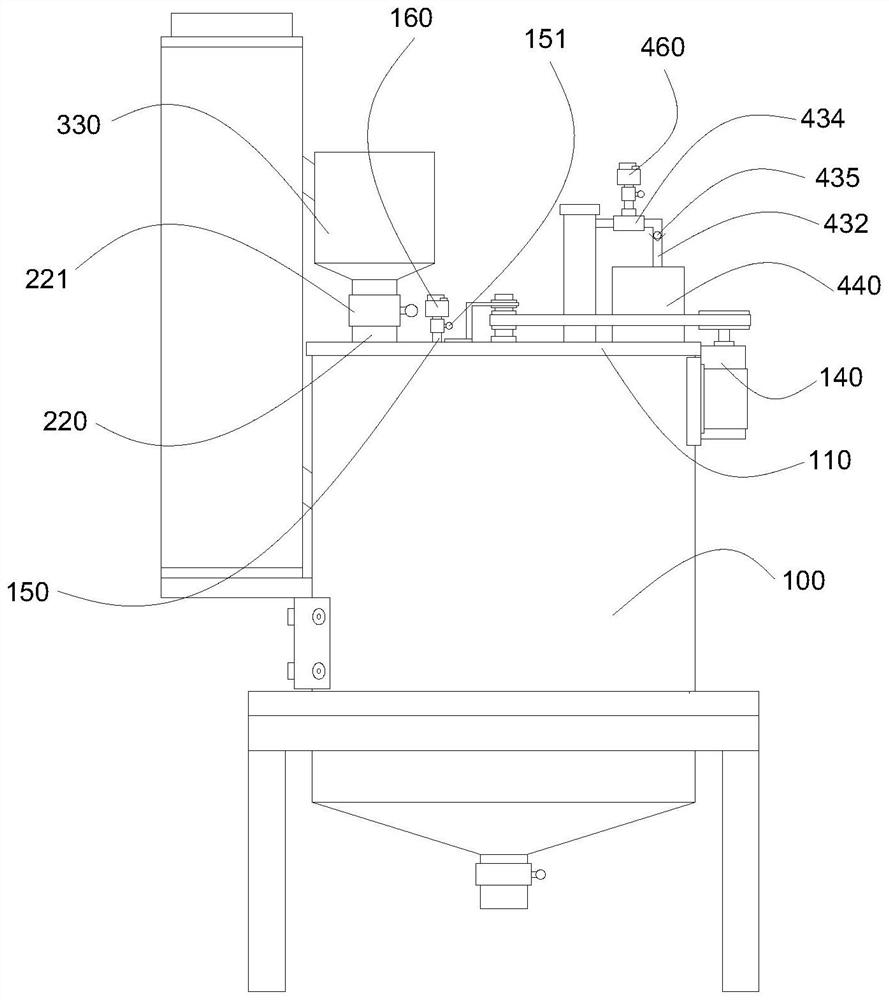

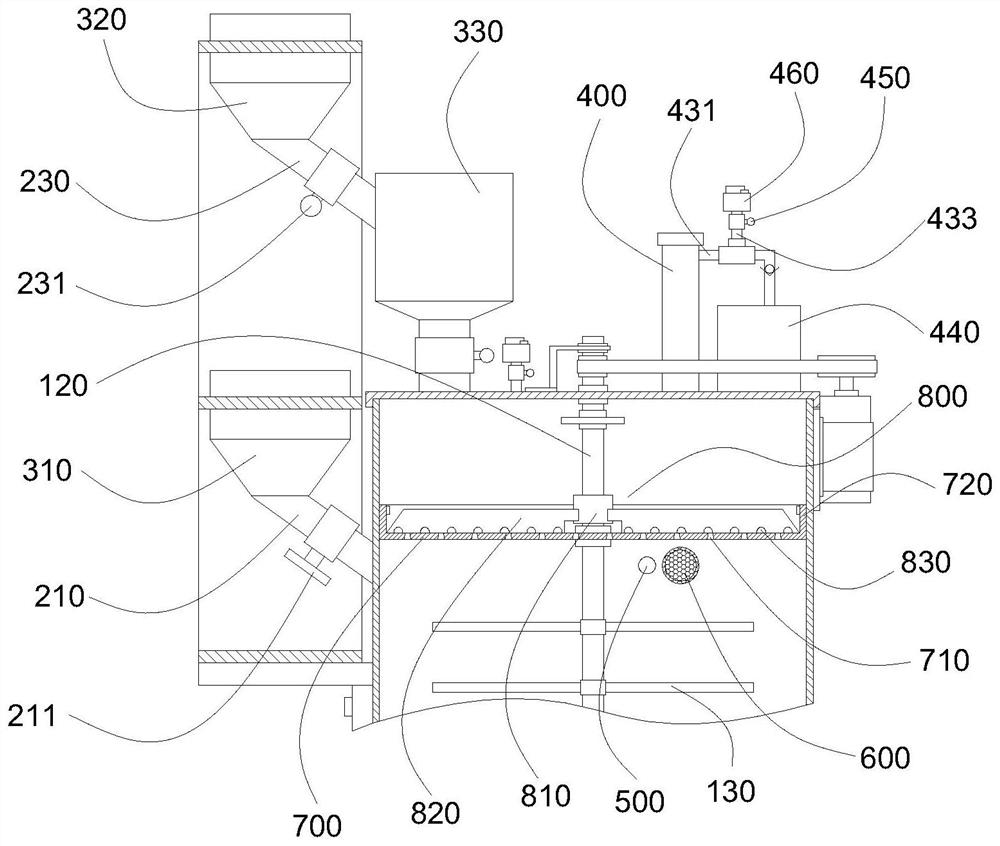

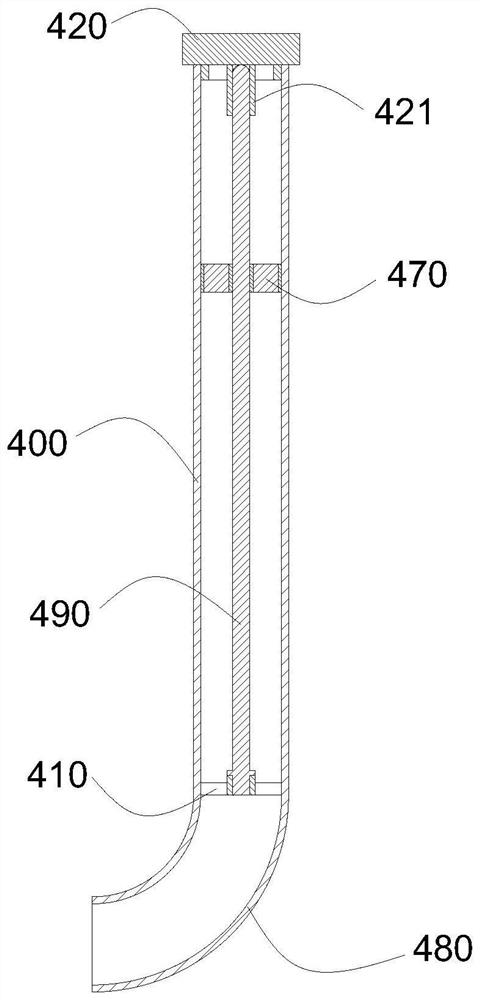

[0023] Such as Figure 1 to Figure 3 As shown, in the specific embodiment of the present invention, a kind of sealing mixing equipment that can carry out secondary feeding is provided, comprises mixing bucket 100, and the top of mixing bucket 100 is provided with bung 110, and the inside of mixing bucket 100 is provided with There is a stirring shaft 120, and the stirring shaft 120 is fixedly provided with a stirring frame 130, and the stirring shaft 120 is driven by a driving motor 140; An electromagnetic valve 211, a first feeding hopper 310 is installed on the top of the first feeding pipe 210; a second feeding pipe 220 is communicated with on the bung 110, and a second electromagnetic valve 221 is arranged on the second feeding pipe 220, and the second feeding The top of the pipe 220 is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com