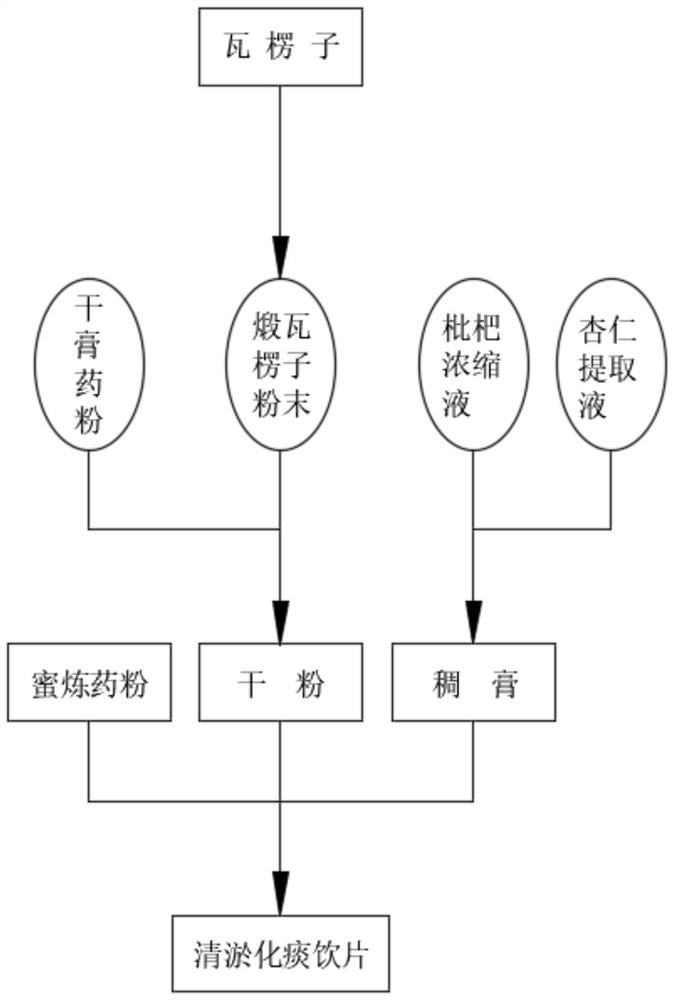

Production process of decoction pieces for dredging and reducing phlegm based on calcined concha arcae

A technology for calcining corrugated seeds and a production process is applied in the field of production technology of decoction pieces for clearing silt and phlegm. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Prepare dry powder, comprise the steps:

[0020] Wash 100kg of corrugated nuts, dry and crush them, add 1kg of table salt and mix them evenly, then calcinate at 800°C for 1.5h, then quench the corrugated nuts with 400mL of 8% acetic acid solution to obtain calcined corrugated nuts; The calcined corrugated fruit is first twisted with a roller press, then transferred to a ball mill for continuous grinding, and passed through a 90-mesh sieve to obtain calcined corrugated fruit powder;

[0021] Mix 5kg Ganoderma lucidum, 8.5kg Gastrodia elata, and 10kg tangerine peel, grind them with a grinder, pass through a 60-mesh sieve, add 10 times the mass of water to extract 3 times, filter, combine the filtrate, concentrate the filtrate, dry it, grind it with a grinder, pass 100 Mesh sieve to obtain dry plaster powder, 200g dry plaster powder and 550g calcined corrugated seed powder are mixed to obtain dry powder.

Embodiment 2

[0023] Prepare dry powder, comprise the steps:

[0024] Wash 100kg of corrugated nuts, dry and crush them, add 1.1kg of salt, mix them evenly, and then calcinate them at 900°C for 2 hours, then quench the corrugated nuts with 500mL of 8% acetic acid solution to obtain calcined corrugated nuts; The calcined corrugated fruit is first twisted with a roller press, then transferred to a ball mill for continuous grinding, and passed through a 100-mesh sieve to obtain calcined corrugated fruit powder;

[0025] Mix 5kg of Ganoderma lucidum, 11kg of Gastrodia elata, and 12kg of tangerine peel, crush them with a pulverizer, pass through a 70-mesh sieve, add 10 times the mass of water to extract 3 times, filter, combine the filtrate, concentrate and dry the filtrate, and pulverize it with a pulverizer, and pass through a 120-mesh Sieve to obtain dry plaster powder, and mix 200g dry plaster powder and 580g calcined corrugated seed powder to obtain dry powder.

Embodiment 3

[0027] The preparation of honey refining medicinal powder comprises the following steps:

[0028] Add 200mL of boiling water to 1.5L of refined honey, continue heating for 10 minutes and keep stirring, add 3.5kg of fried gardenia and 4kg of licorice and continue stirring for 20 minutes, so that the surface of fried gardenia and licorice is covered with refined honey; at 50°C Continue frying until the condensed honey on the surface of the fried gardenia and licorice is dry, pulverize with a pulverizer and pass through a 100-mesh sieve to obtain the condensed honey powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com