Hot-melt pressure-sensitive adhesive for RFID electronic tag and preparation method of hot-melt pressure-sensitive adhesive

A hot-melt pressure-sensitive adhesive and electronic label technology, used in pressure-sensitive films/sheets, adhesives, heat-activated films/sheets, etc. , strong adhesion, excellent high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

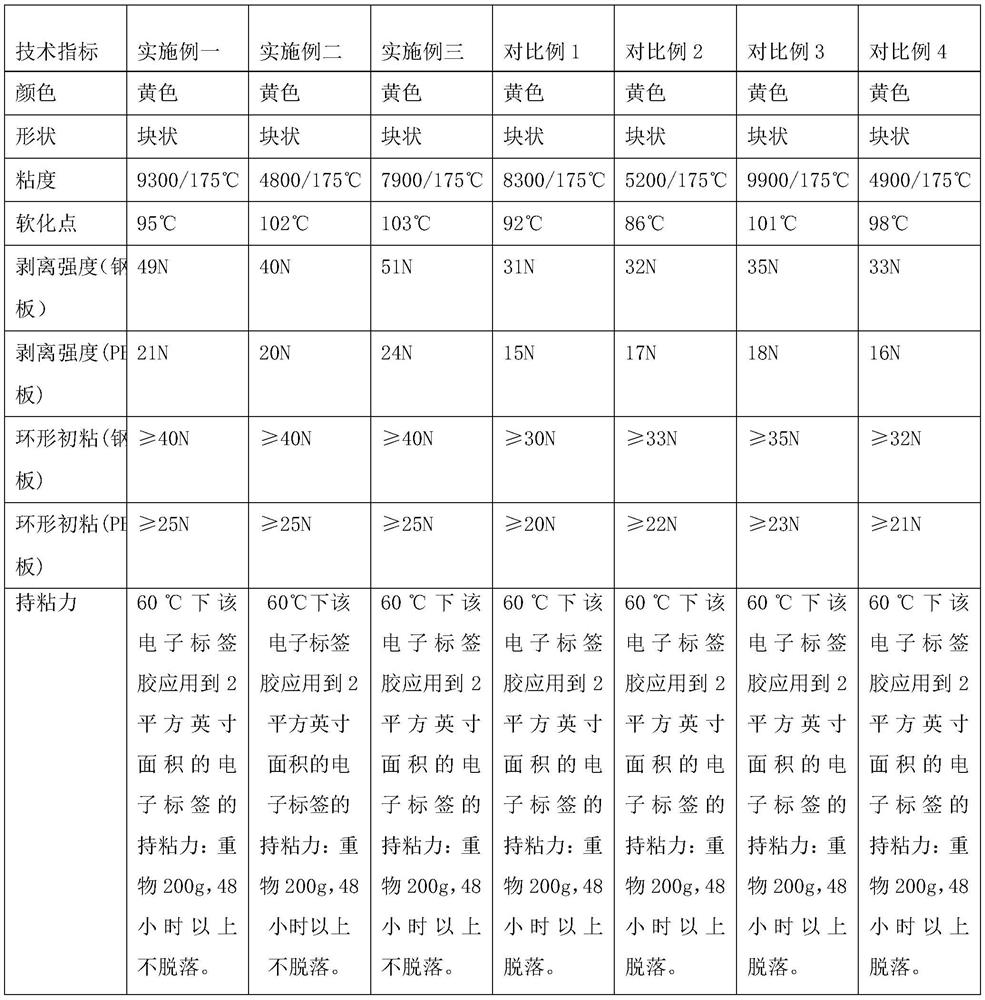

Examples

Embodiment 1

[0028] A hot-melt pressure-sensitive adhesive for RFID electronic tags, comprising the following raw materials in parts by weight: 45 parts of styrene-isoprene-styrene block copolymer, 35 parts of tackifying resin, 35 parts of softener, and 0.5 parts of antioxidant Part; the styrene-isoprene-styrene block copolymer is the styrene-isoprene-styrene block copolymer of specification A and specification B in a weight ratio of 7:1, the The styrene-isoprene-styrene block copolymer of specification A has a SI content of 50% and the styrene content of 16%; the styrene-isoprene-styrene block copolymer of specification B The SI content is 30%, and the styrene content is 19%.

[0029] The tackifying resin is a mixture of rosin resin and hydrogenated petroleum resin in a weight ratio of 5:9.

[0030] The softening point of the rosin resin is 90°C, and the softening point of the hydrogenated petroleum resin is ≥97°C.

[0031] The softener is a mixture of naphthenic oil and liquid polyisob...

Embodiment 2

[0040]A hot-melt pressure-sensitive adhesive for RFID electronic tags, comprising the following raw materials in parts by weight: 30 parts of styrene-isoprene-styrene block copolymer, 70 parts of tackifying resin, 20 parts of softener, and 2 parts of antioxidant part; the styrene-isoprene-styrene block copolymer is the styrene-isoprene-styrene block copolymer of specification C and specification D in a weight ratio of 5:3, and the The styrene-isoprene-styrene block copolymer of specification C has a SI content of 60% and the styrene content of 15%; the styrene-isoprene-styrene block copolymer of specification D The SI content is 0%, and the styrene content is 29%.

[0041] The tackifying resin is a mixture of rosin resin and hydrogenated petroleum resin in a weight ratio of 2:5.

[0042] The softening point of the rosin resin is 110°C, and the softening point of the hydrogenated petroleum resin is ≥97°C.

[0043] The softener is a mixture of naphthenic oil and liquid polyiso...

Embodiment 3

[0052] A hot-melt pressure-sensitive adhesive for RFID electronic tags, comprising the following raw materials in parts by weight: 40 parts of styrene-isoprene-styrene block copolymer, 55 parts of tackifying resin, 30 parts of softener, and 1 part of antioxidant part; the styrene-isoprene-styrene block copolymer is the styrene-isoprene-styrene block copolymer of specification A and specification B in a weight ratio of 6:2, the The styrene-isoprene-styrene block copolymer of specification A has a SI content of 50% and the styrene content of 16%; the styrene-isoprene-styrene block copolymer of specification B The SI content is 30%, and the styrene content is 19%.

[0053] The tackifying resin is a mixture of rosin resin and hydrogenated petroleum resin in a weight ratio of 3:7.

[0054] The softening point of the rosin resin is 100°C, and the softening point of the hydrogenated petroleum resin is ≥97°C.

[0055] The softener is a mixture of naphthenic oil and liquid polyisobut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com