Aerial fixed type edge cleaning machine

An edge cleaning machine and fixed technology, applied in the direction of ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc., can solve the problems of resource waste and economic loss, high cleaning difficulty, unfavorable packaging, etc., to increase security and simplify action steps , High cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

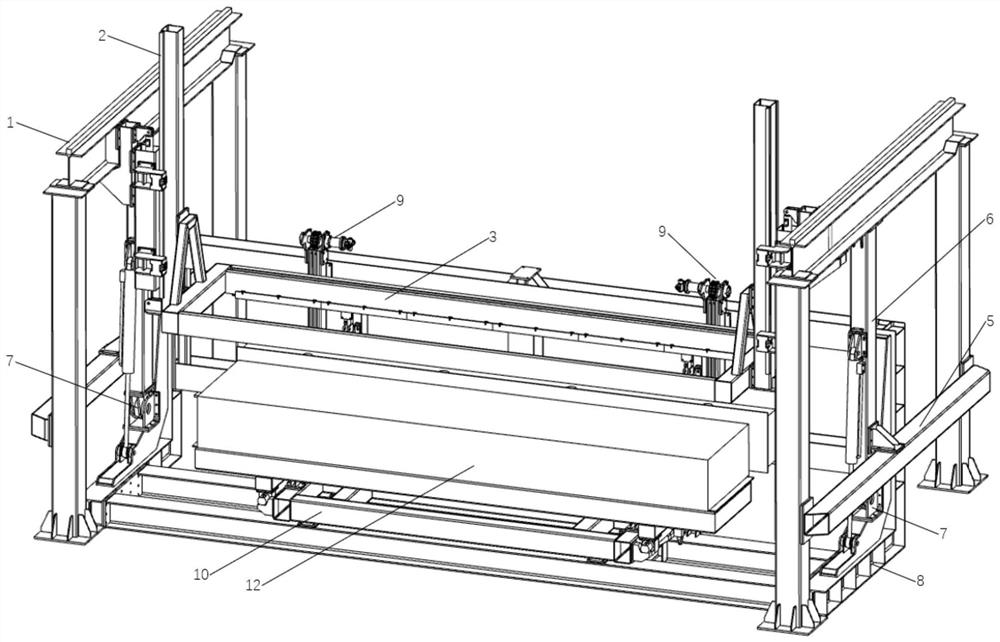

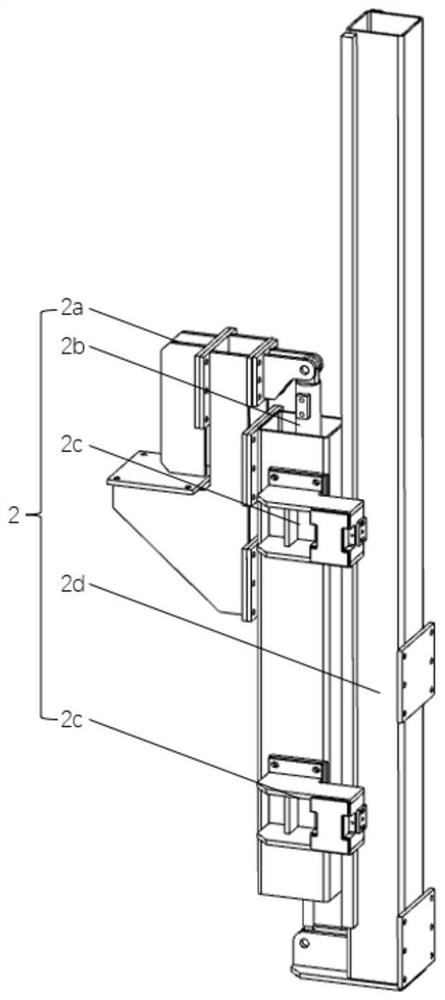

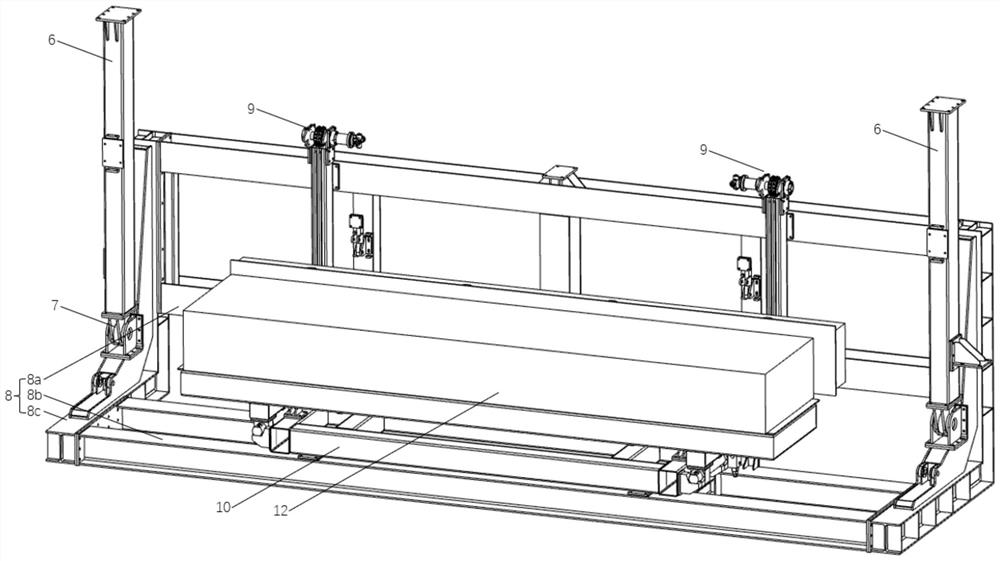

[0030] Such as Figure 1~Figure 6 As shown, the aerial fixed edge cleaning machine includes a pair of parallel and symmetrical gantry frames 1, and each gantry frame 1 is composed of 2 columns and 1 beam at the top. H-shaped steel, the two ends of the beam are concave and the depression is connected with the column. When the gantry structure is erected and disassembled, there are always two columns connected into one body, which is safe and reliable. The distance between two gantry frames is 7.5m-8.5m. , with ample space between them, which is convenient for setting various devices required for edge cleaning, and can adapt to the size of the mainstream aerated concrete body 12 (about 6m in length) on the market; Mechanism 2, the bottom of the lifting mechanism 2 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com