Gear slotting and trepanning process

A gear and process technology, which is applied in the field of gear slotting and hole opening technology, can solve the problems of overlapping of weight-reducing holes and threaded holes, and achieve the effects of avoiding overlapping, good supporting effect, and avoiding scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A gear slotting and drilling process, comprising the steps of:

[0045] Step 1: using a mold to forge four weight-reducing holes 35 on the workpiece 17 at one time, and the four weight-reducing holes 35 are evenly distributed on the workpiece 17;

[0046] Step 2: using existing technology to make teeth on the workpiece 17;

[0047] Step 3: Pull out the keyway with the groove tool;

[0048] Step 4: Position the workpiece 17 with the tapping positioning tool, and process the threaded hole 36 .

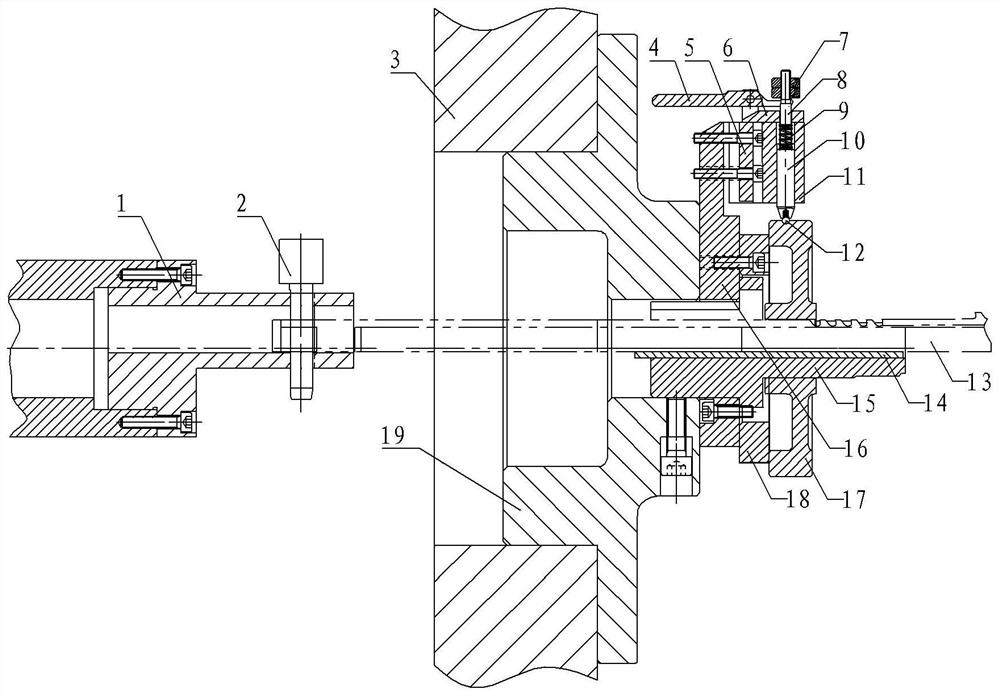

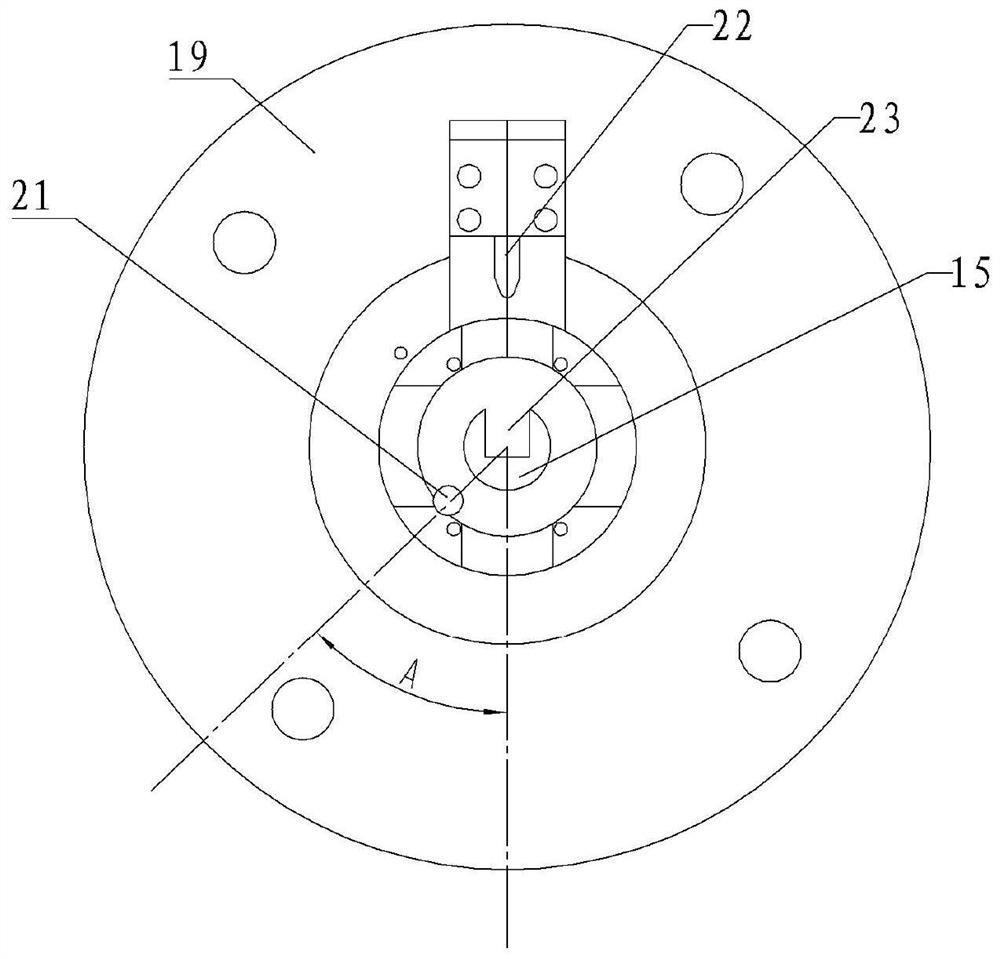

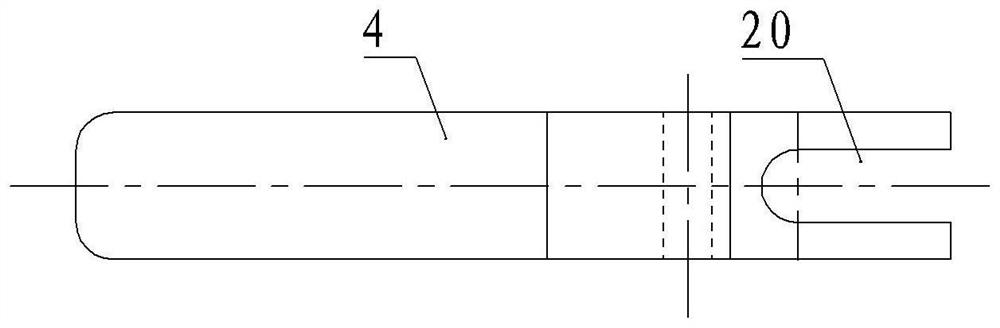

[0049] like figure 1 , figure 2 and image 3 As shown, the groove positioning tool used in step 3 includes a hinge plate 16, a guide sleeve 15 and a positioning mechanism, the guide sleeve 15 is fixed on the hinge plate 16 by bolts, the groove washer 18 is set on the guide sleeve 15, and the groove washer 18 is also fixed on the hinge plate 16 by bolts. The hinge plate 16 is provided with a limit pin 21, the limit pin 21 penetrates the slotted washer 18 along the axial dire...

Embodiment 2

[0063] The difference between this embodiment and Embodiment 1 is that the included angle A is 30 degrees, and the workpiece 17 is as Figure 8 As shown, that is, when four uniformly distributed weight-reducing holes 35 are opened, and the included angle A is 30 degrees, the weight-reducing holes 35 and the threaded holes 36 will not overlap.

Embodiment 3

[0065] The difference between this embodiment and Embodiment 1 is that the included angle A is 60 degrees, and the workpiece 17 is as Figure 9 As shown, that is, when four evenly distributed weight-reducing holes 35 are opened, and the included angle A is 60 degrees, the weight-reducing holes 35 and the threaded holes 36 will not overlap.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com