Equipment and method for preparing alloy nanoparticles by electric arc method

A technology of alloy nanoparticles and arc method, applied in the direction of nanotechnology, can solve the problems of difficult adjustment and control, low work efficiency, low alloy powder content, etc., and achieve novel structure, simple and effective operation, and narrow particle size distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

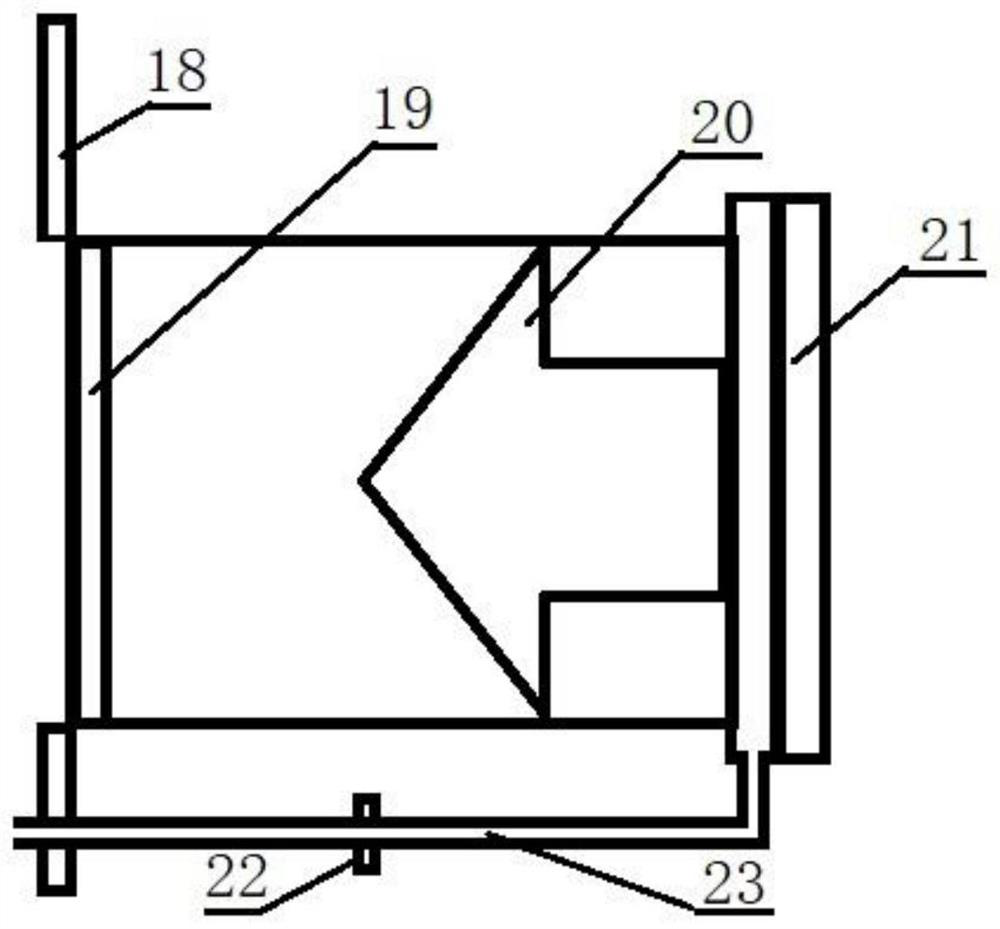

[0047] ①. Put the alloy block (such as: CuAl) cake to be evaporated with a diameter of 39 mm and a height of 14 mm, and place five tungsten sheets of a diameter of 3 mm and a height of 1 mm on the water-cooled anode, and a water-cooled and ventilated cathode tungsten rod with a diameter of 4 mm and a length of 115 mm as the cathode head; Turn on the circulating water and the power supply, and use the mechanical pump and the molecular pump unit to vacuumize the vapor deposition chamber 8 and the sealing chamber 9 to 2×10 -1 Pa's environment. Then vapor deposition chamber 8 and sealing chamber 9 are filled with argon gas, cleaned 2-3 times, and finally vacuumized to 2 × 10 -3 Pa's environment;

[0048] ② Fill in hydrogen-argon mixed gas, the total pressure of hydrogen-argon mixed gas is 9.5×10 4 Pa, where the pressure ratio of argon to hydrogen is P Ar :P H2 = 1:1;

[0049] ③. Turn on the temperature-controllable columnar heater, adjust the temperature to 500°C, start the c...

Embodiment 2

[0053] ①. Put the alloy block (such as: CuAl) cake to be evaporated φ40mm, 15mm high, and place two φ4mm, 1mm high tungsten sheets in the middle on the water-cooled anode, and the water-cooled and ventilated cathode tungsten rod φ5mm, 120mm long as the cathode head ; Turn on the circulating water and the power supply, and utilize the mechanical pump and the molecular pump unit to vacuumize the vapor deposition chamber 8 and the sealing chamber 9 to 2×10 -1 Pa's environment. Then vapor deposition chamber 8 and sealing chamber 9 are filled with argon gas, cleaned 2-3 times, and finally vacuumized to 2 × 10 -3 Pa's environment;

[0054] ② Fill in hydrogen-argon mixed gas, the total pressure of hydrogen-argon mixed gas is 9.5×10 4 Pa, where the pressure ratio of argon to hydrogen is P Ar :P H2 =2:1;

[0055] ③. Turn on the temperature-controllable column heater, adjust the temperature to 800°C, start the circulation pump, and then adjust the cathode ventilation to 30 sccm;

...

Embodiment 3

[0059] ①. Put the alloy block (such as: CuAl) to be evaporated (such as: CuAl) cake with a diameter of 41mm and a height of 16mm, and place five tungsten sheets of a diameter of 4mm and a height of 1.5mm in the middle on the water-cooled anode, and a water-cooled and ventilated cathode tungsten rod of dia. ; Turn on the circulating water and the power supply, and utilize the mechanical pump and the molecular pump unit to vacuumize the vapor deposition chamber 8 and the sealing chamber 9 to 2×10 -1 Pa's environment. Then vapor deposition chamber 8 and sealing chamber 9 are filled with argon gas, cleaned 2-3 times, and finally vacuumized to 2 × 10 -3 Pa's environment;

[0060] ② Fill in hydrogen-argon mixed gas, the total pressure of hydrogen-argon mixed gas is 9.5×10 4 Pa, where the pressure ratio of argon to hydrogen is P Ar :P H2 =4:1;

[0061] ③. Turn on the temperature-controllable column heater, adjust the temperature to 1000°C, start the circulation pump, and then ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com