A liquid nitrogen cryogenic granulation equipment

A kind of equipment, liquid nitrogen technology, applied in the field of liquid nitrogen cryogenic granulation equipment, can solve the problems of unstable fermentation activity, high price, unstable between batches, etc., to solve the problem of dosage form and equipment, low production cost, Effects of increasing pellet temperature and drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

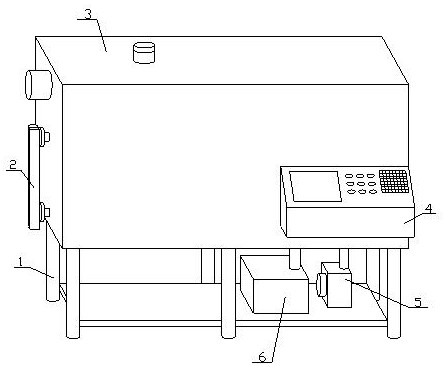

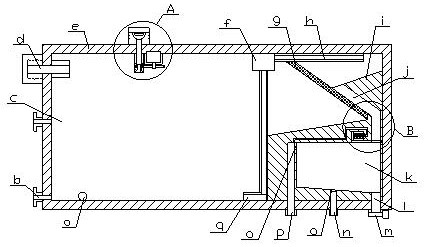

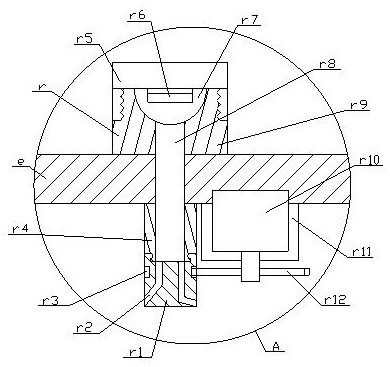

[0032] see figure 1 , figure 2 , image 3 and Figure 4 , The present invention provides a liquid nitrogen cryogenic granulation equipment: its structure includes a chassis 1, a magnetic flap level gauge 2, a granulation equipment 3, a controller 4, a hot air blower 5, and a vacuum pump 6. The granulation equipment 3. The bottom end is fixedly connected with the chassis 1, the side end of the granulation equipment 3 is locked with a magnetic flap level gauge 2, the controller 4 is arranged on the granulation equipment 3, the hot air blower 5, the vacuum pump 6 Both are fixedly connected with the chassis 1, and the hot air blower 5 and the vacuum pump 6 are all fixedly connected with the bottom of the granulation equipment 3;

[0033]The granulation equipment 3 includes a nitrogen discharge port a, a liquid level measurement joint b, a granulation tank c, a liquid nitrogen addition pipe d, a main box e, a suction pump f, a particle filter plate g, a conduit h, and a granula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com