Oil gel and preparation method and use thereof

An oil-gel and oil-phase technology, which can be used in applications, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of accelerating the oxidation of unsaturated fatty acids, and achieve high antioxidant properties, simple components, and simple preparation processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The method of preparation of the product

[0050] The oleogel of the present invention can be prepared by mixing a structuring agent, such as whey protein denatured particles, with liquid oil to form an oil phase suspension, and then adding water. For whey protein denatured granules, a whey protein suspension with a concentration range of 2-25% can be prepared, and after being fully dissolved by magnetic stirring, the denatured protein granules can be prepared by heating at 75-100°C for 30-100 minutes; after drying, Denatured protein powder. 6~35% whey protein denatured granules can be mixed with liquid oil, such as algae oil rich in Omega-3 polyunsaturated fatty acids, and homogenized to obtain an oil phase suspension of whey protein, and then, can be added to the above suspension Add 4~15% water to the mixture, then homogeneously obtain the oil gel of the present invention. The method may not include the step of heating the liquid oil. Herein, heating may be heatin...

Embodiment 1

[0094] Embodiment 1: Structural characterization of oil composition

[0095] 1. Prepare the oil gel according to the formula in Table 1. Specifically, 18wt% whey protein denatured particles were added to 70wt% algae oil rich in Omega-3 polyunsaturated fatty acids, mixed for 0.5-3h to obtain protein oil phase suspension; then 12wt% purified water was added to In the above oil phase suspension, the oil gel rich in Omega-3 polyunsaturated fatty acids is obtained after homogenizing for 3-30 minutes.

[0096] Table 1: Formulations of Oleogels

[0097]

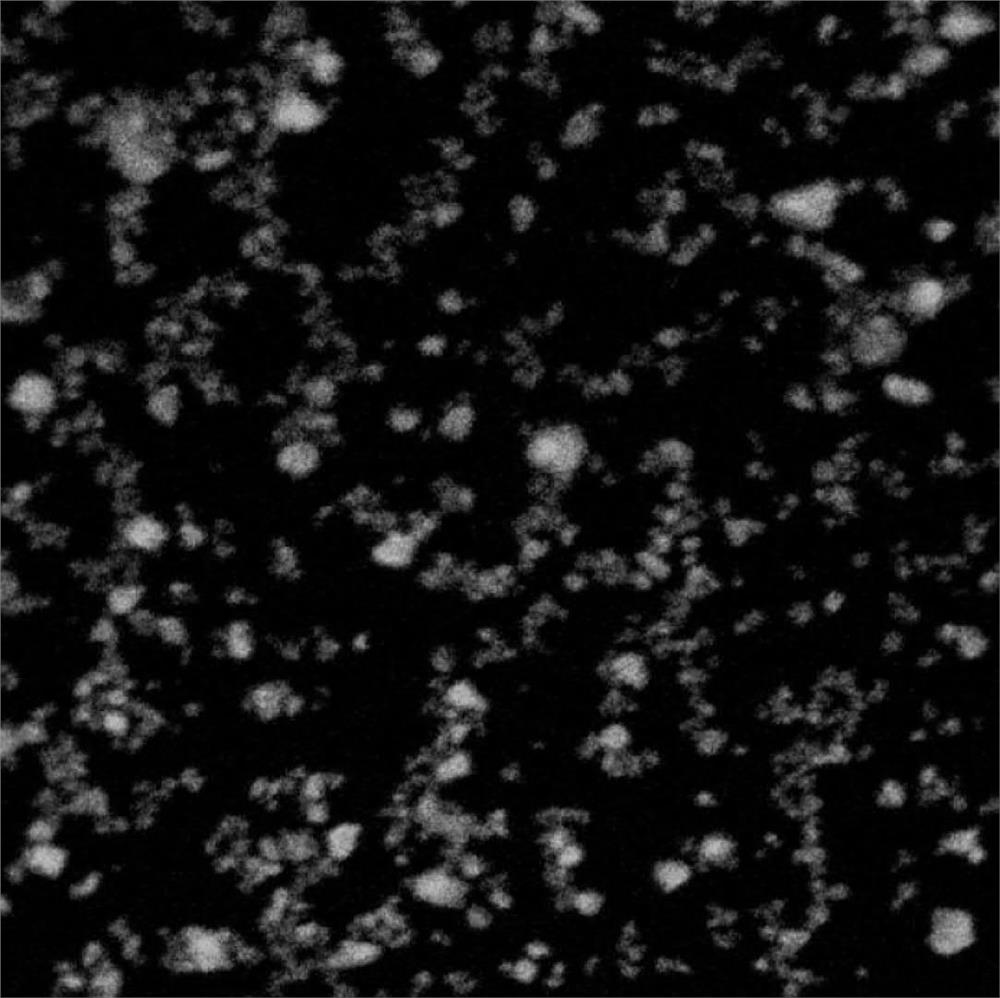

[0098] Oleogels were microscopically observed (stained) for structural characterization: protein particles were stained with Thioflavin T (Th T) fluorescence during preparation; , Germany) captures the imaging of protein particles or networks with an excitation wavelength of 458 nm.

[0099] figure 2 The results of the formation of osmotic networks by protein particles in oil and fat compositions are shown in . according to...

Embodiment 2

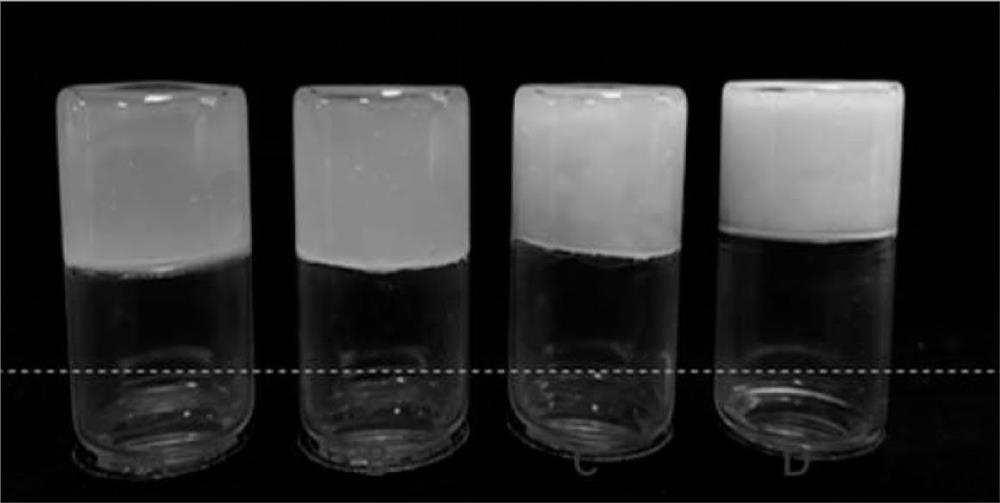

[0103] Example 2: Investigation of the amount of denatured protein particles added

[0104] Evaluation of the rheological properties and peroxide value of the oleogel formulations for the content of denatured particles of whey protein. Specifically, the quality of algae oil and water (70 g and 12 g, respectively) was controlled, the quality of protein denatured particles (in g) was changed, and the rheological properties and peroxide value were determined by the method described above. The results are shown in Table 2.

[0105] Table 2: Effects of different amounts of protein denatured particles added on rheological properties and peroxide value

[0106]

[0107] Unformed: refers to that the prepared composition is in the form of liquid or obviously fluid suspension oil, which cannot be condensed into solid or semi-solid.

[0108] According to Table 2, the oil gel can be prepared when the protein denatured particle content is 6-35%, and the oil gel cannot be formed when the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peroxide value | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com