Ester fragrant sour soup containing anthocyanin and brewing method thereof

A technology of anthocyanin and ester-flavored sour soup, applied in biochemical equipment and methods, specific-purpose bioreactors/fermenters, biochemical instruments, etc. To solve problems such as large flavor differences, achieve the effects of improving flavor quality, nutritional value and taste, precise regulation and increasing the total amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

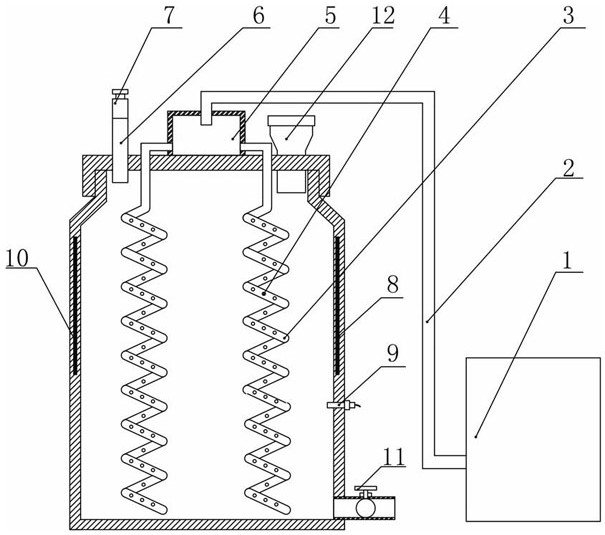

Image

Examples

Embodiment 1

[0065] A preparation method of anthocyanin-containing ester-flavored sour soup, comprising the following steps:

[0066] S1. Raw material handling:

[0067] After the selected qualified tomatoes, bright red peppers and ginger are washed and drained, they are crushed into pulp respectively.

[0068] S2. Ingredients:

[0069] According to the formula, 35 parts of crushed tomatoes, 4 parts of fresh red pepper, 1 part of ginger and 2 parts of edible salt are mixed and stirred evenly to obtain a mixed slurry.

[0070] S3. Primary fermentation:

[0071] Add 0.05 parts of lactic acid bacteria into the mixed slurry according to the formula and stir evenly, then put it into a fermenter for sealed fermentation for 80 days.

[0072] When fermenting to 20 days, open the fermenter, add the fruit and vegetable slurry therein and stir evenly, then seal it, and continue to ferment until the end to obtain the fermentation slurry;

[0073] The preparation steps of the fruit and vegetable sl...

Embodiment 2

[0084] A preparation method of anthocyanin-containing ester-flavored sour soup, comprising the following steps:

[0085] S1. Raw material handling:

[0086] S11. Select qualified rice and crush it into particles with a fineness of 80 meshes, add 2-3 times the weight of rice to the rice, add amylase 0.04 times the weight of rice and glucoamylase 0.2 times the weight of rice and stir evenly, then carry out Liquefaction and saccharification for 20 hours to make rice slurry;

[0087] S12. Select qualified purple sweet potatoes and crush them into particles with a fineness of 100 mesh, add 2-3 times the weight of purple sweet potatoes to water, and add 0.1 times the weight of purple sweet potato amylase and 0.4 times the weight of purple sweet potato glucoamylase After stirring evenly, carry out liquefaction and saccharification for 24 hours to make purple sweet potato slurry;

[0088] S13. After washing and draining the selected qualified tomatoes, bright red peppers and ginger,...

Embodiment 3

[0105] A preparation method of anthocyanin-containing ester-flavored sour soup, comprising the following steps:

[0106] S1. Raw material handling:

[0107] S11. Select qualified rice and crush it into particles with a fineness of 80 meshes, add 2-3 times the weight of rice to the rice, add amylase 0.04 times the weight of rice and glucoamylase 0.2 times the weight of rice and stir evenly, then carry out Liquefaction and saccharification for 36 hours to make rice slurry;

[0108] S12. Select qualified purple sweet potatoes and crush them into particles with a fineness of 100 mesh, add 2-3 times the weight of purple sweet potatoes to water, and add 0.1 times the weight of purple sweet potato amylase and 0.4 times the weight of purple sweet potato glucoamylase After stirring evenly, carry out liquefaction and saccharification for 30 hours to make purple sweet potato slurry;

[0109] S13. After washing and draining the selected qualified tomatoes, bright red peppers and ginger,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com