Energy-saving and environment-friendly tin concentrate smelting and discharging device and production process thereof

An energy-saving and environmental-friendly, furnace-extracting device technology, which is applied in the direction of furnaces, furnace components, and discharged materials, can solve the time-consuming and labor-intensive problems of tin slag separation, and achieve the effects of avoiding smoke and dust overflow, avoiding environmental pollution, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

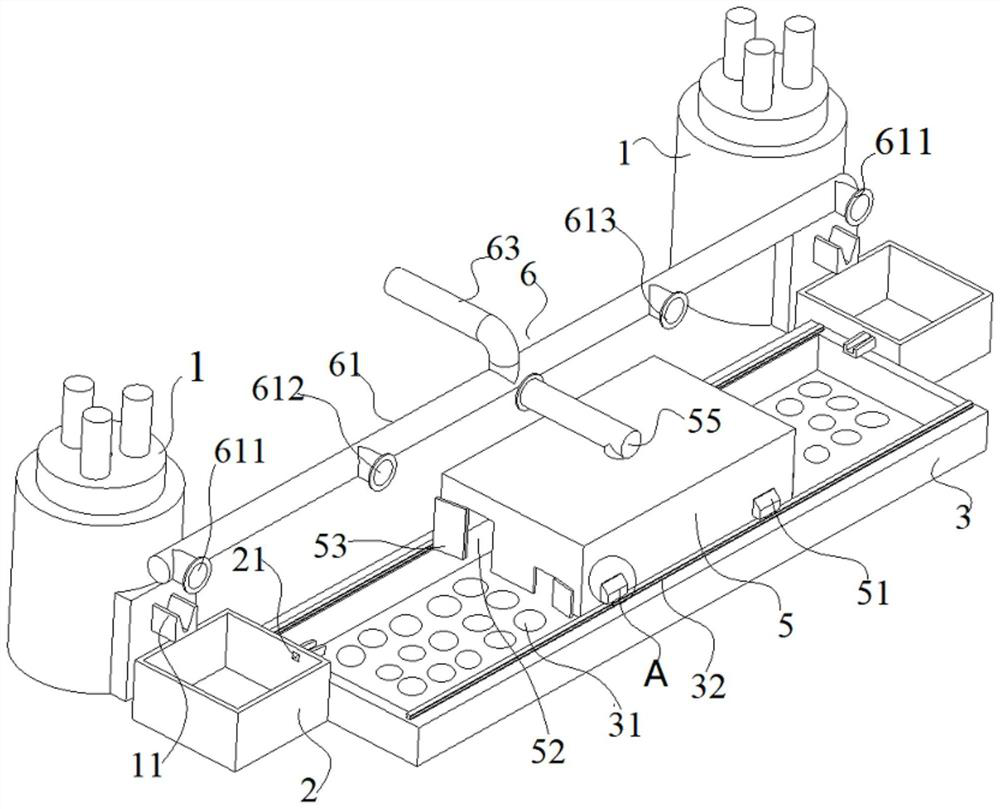

[0039] The energy-saving and environment-friendly tin concentrate smelting and tapping device of the present embodiment, such as figure 1 As shown, it includes a settling tank 2, a standing forming tank 3, a reciprocating cover 5 and an exhaust mechanism 6, wherein: the settling tank 2 is arranged in pairs and symmetrically distributed on both sides of the standing forming tank 3; each settling The pools 2 are all close to the discharge port 11 of the corresponding smelting electric furnace 1, and the upper part of the sedimentation pool 2 has an overflow port 21, and the overflow port 21 leads to the static forming pool 3, and the bottom of the static forming pool 3 is distributed with tin supply A plurality of forming blind holes 31 formed by the slag forming ingot 4; the reciprocating cover 5 is covered above the static forming pool 3, and the top of the reciprocating cover 5 is communicated with and fixed with a ventilation pipe 55; the exhaust mechanism 6 is fixed laterall...

Embodiment 2

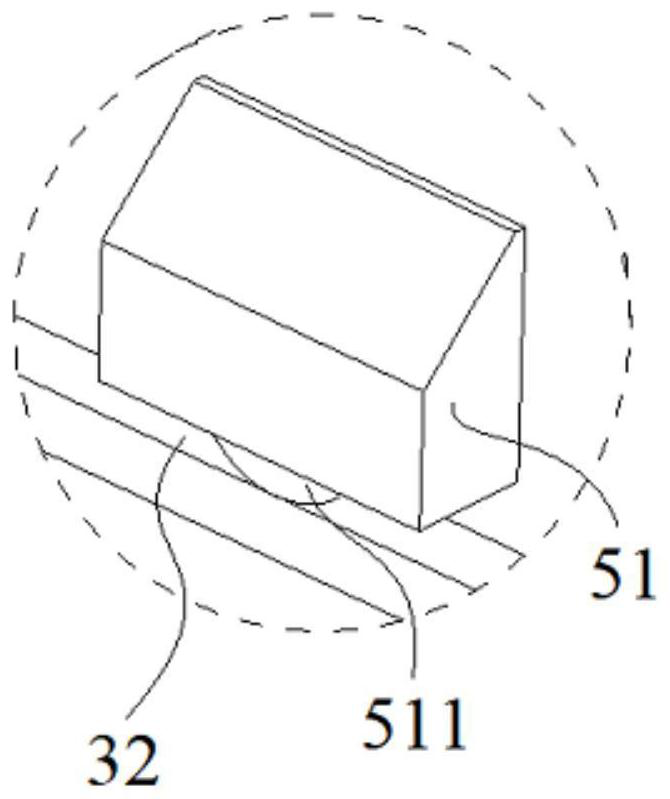

[0045] The energy-saving and environment-friendly tin concentrate smelting and tapping device of this embodiment has the same basic structure as that of Embodiment 1, the differences and improvements are that sliders 51 are fixed on the front and rear side walls of the reciprocating cover 5, and the bottom of the reciprocating cover 5 sinks Put into the bottom of the static forming pool 3 and close to the forming blind hole 31; the pool edge of the static forming pool 3 is fixed with a guide rail 32 cooperating with the slide block 51, and the reciprocating cover 5 reciprocates on the guide rail 32 During the process, it plays the role of sealing and scraping, that is, the smoke and dust generated during the standing process is sealed in the reciprocating cover 5 and then discharged through the top ventilation pipe 55. During the process of discharging, the tin in the forming blind hole 31 The slag also plays the role of cooling and forming, and, during the movement of the reci...

Embodiment 3

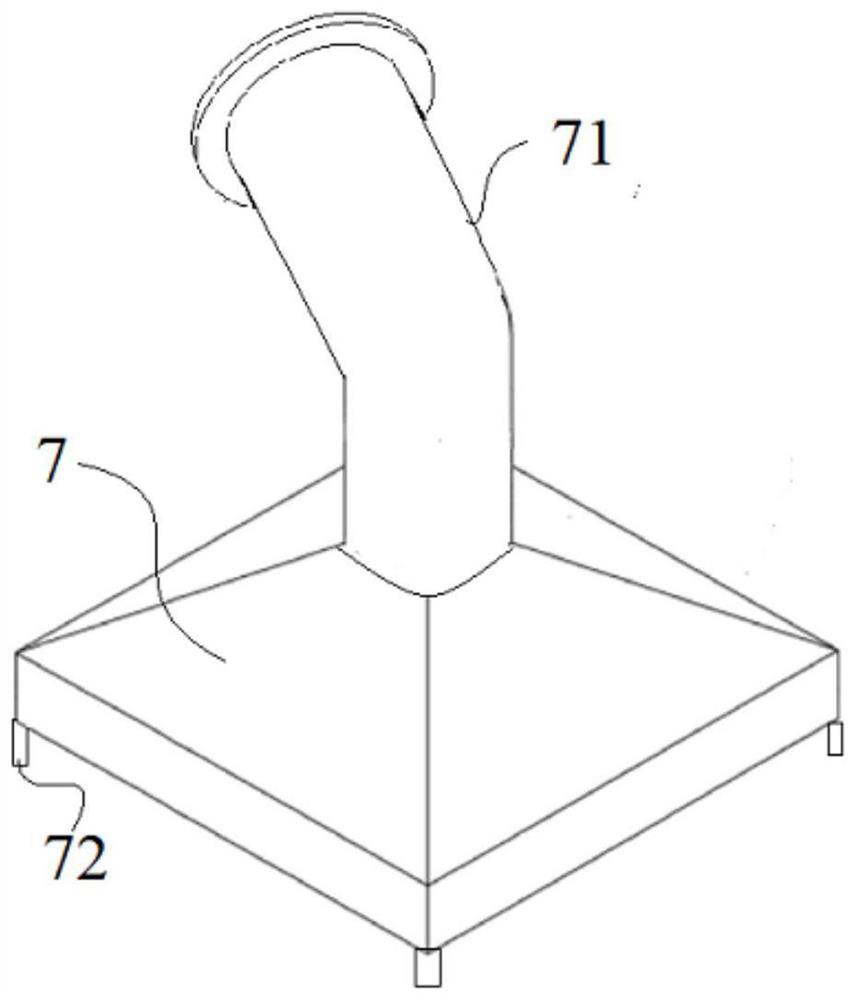

[0054] An energy-saving and environment-friendly tin concentrate smelting and tapping device of this embodiment has the same basic structure as that of Embodiment 2, the differences and improvements are as follows: figure 2 As shown, the bottom of the slider 51 is rotatably connected with a roller 511, which converts sliding into rolling, saving time and effort. The forming blind hole 31 is a frustum or cone shape, such as Figure 4 , 5 As shown, the molded tin slag molding ingot 4 is in a corresponding frustum or cone shape, and the molding blind hole 31 is similar to a mould, which is convenient for mold removal, and the handle bar 41 is preset inside, so that it can be removed from the molding blind hole after molding. It is proposed that the bottom of the dust collection cover 7 is symmetrically fixed with an elastic mechanism 72, such as a spring or a shrapnel, so that there is a certain margin when the ventilation pipe 71 on the top is docked with the gas collection br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com