Tin concentrate recyclable smelting system and processing technology thereof

A technology of tin concentrate and tin liquid, which is applied in the recyclable smelting system of tin concentrate and its processing technology, can solve the problems affecting the balanced temperature rise of materials, uneven temperature rise of concentrate, and unbalanced smelting, so as to reduce heat loss , Avoid environmental pollution, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

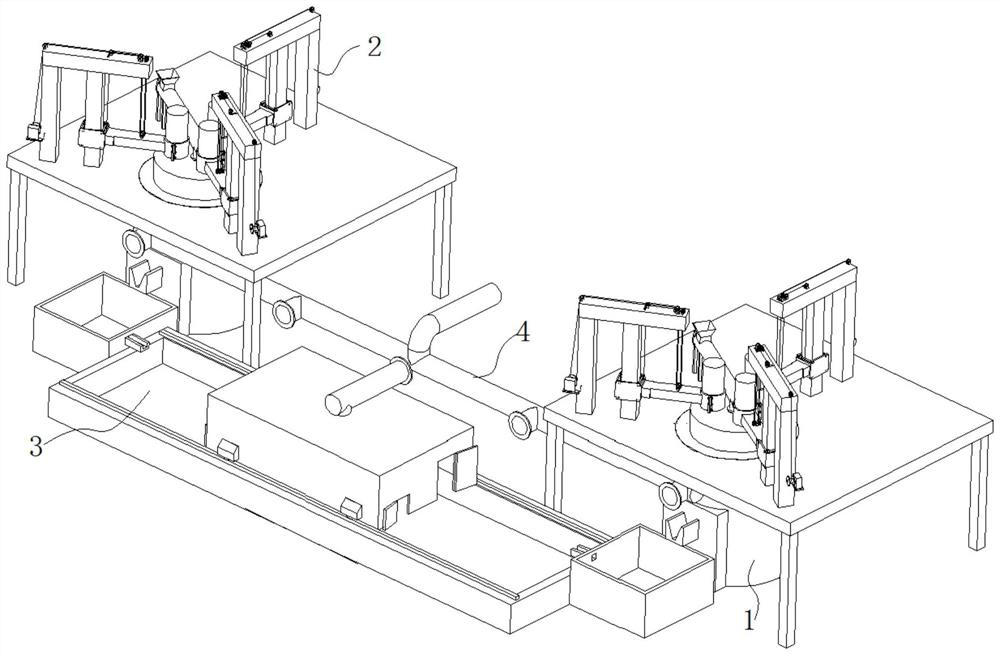

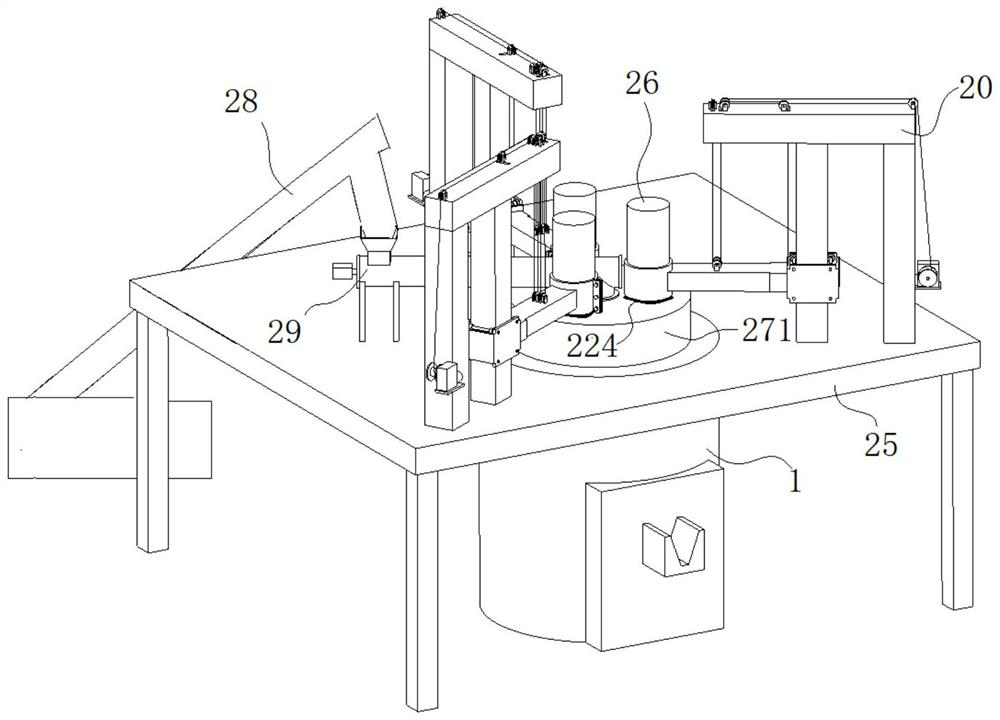

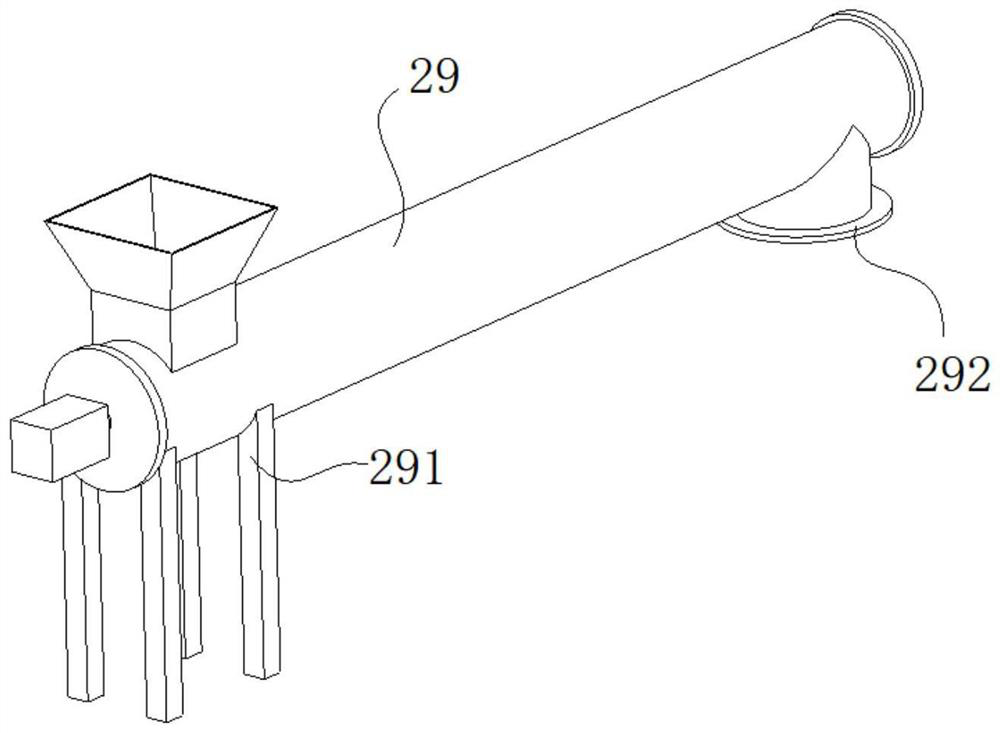

[0053] The tin concentrate recyclable smelting system of the present embodiment, such as figure 1 As shown, it includes a smelting electric furnace 1, a synchronous replacement device 2 for electrode rods on the top of the smelting electric furnace 1, and a tin liquid processing device 3 after the smelting electric furnace 1 is smelted and discharged, wherein: as figure 1 and 8 As shown, the tin liquid treatment device 3 includes a sedimentation tank 32 and a static forming tank 33, the sedimentation tank 32 is arranged at the bottom of the discharge port 11 of the smelting electric furnace 1, and the upper part of the sedimentation tank 32 is opened with an overflow port 321 and a static forming tank 33 are connected; the tin slag on the upper layer of the sedimentation tank 32 flows into the standing forming tank 33 through its overflow port 321, and the refined tin liquid on the lower layer is transported to the next process through its bottom outlet; figure 2 As shown, t...

Embodiment 2

[0062] The tin concentrate recyclable smelting system of this embodiment has the same basic structure as that of Embodiment 1, the difference and improvement is that: the forming blind hole 331 is in the shape of a cone or a cone, and the molded tin slag ingot is in the shape of a corresponding cone Or cone-shaped, the forming blind hole is similar to the mold, which is convenient for mold removal, and the handle bar 341 is preset inside, which is convenient to lift out of the forming blind hole after forming; Figure 4 As shown, the vertical fixed frame 21 includes a vertical support column 212 and a support guide column 213 inside the support column 212, and also includes a boom 211 that is fixedly connected to the top of the support column 212 and the support guide column 213 in a horizontal direction; the support column 212 and the supporting guide column 213 are fixedly connected to the support platform 25; one end of the lifting arm 22 is fixedly connected with a guide fr...

Embodiment 3

[0064] A kind of tin concentrate recyclable smelting system of the present embodiment, the basic structure is the same as embodiment 2, the differences and improvements are as follows: Figure 6 As shown, the pulley mechanism 24 also includes the fifth fixed pulley 245 near the second through hole 2112 and the second movable pulley 247 on the upper surface of the lifting arm 22 parallel to the first movable pulley 246, the fifth fixed pulley 245 and the third fixed pulley 243 are arranged in the second through hole 2112 the two sides of the traction rope 231; the free end of the traction rope 231 walks around fixed pulley one 241, fixed pulley four 244, passes through hole two 2112 downwards, then walks around movable pulley one 246, passes through hole two 2112 upwards, and then winds Pass fixed pulley five 245, pass through hole two 2112 downwards, walk around movable pulley two 247, pass through hole two 2112 upwards, bypass fixed pulley three 243, fixed pulley two 242, pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com