Chemical flash dryer device capable of preventing material accumulation and intercepting agglomerated particles

A flash dryer and agglomeration technology, which is applied in the direction of drying gas arrangement, granular material drying, non-progressive dryer, etc., can solve the problems of affecting material drying, wasting power resources, and difficult to clean up, so as to improve drying efficiency. Efficiency, the effect of increasing the drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

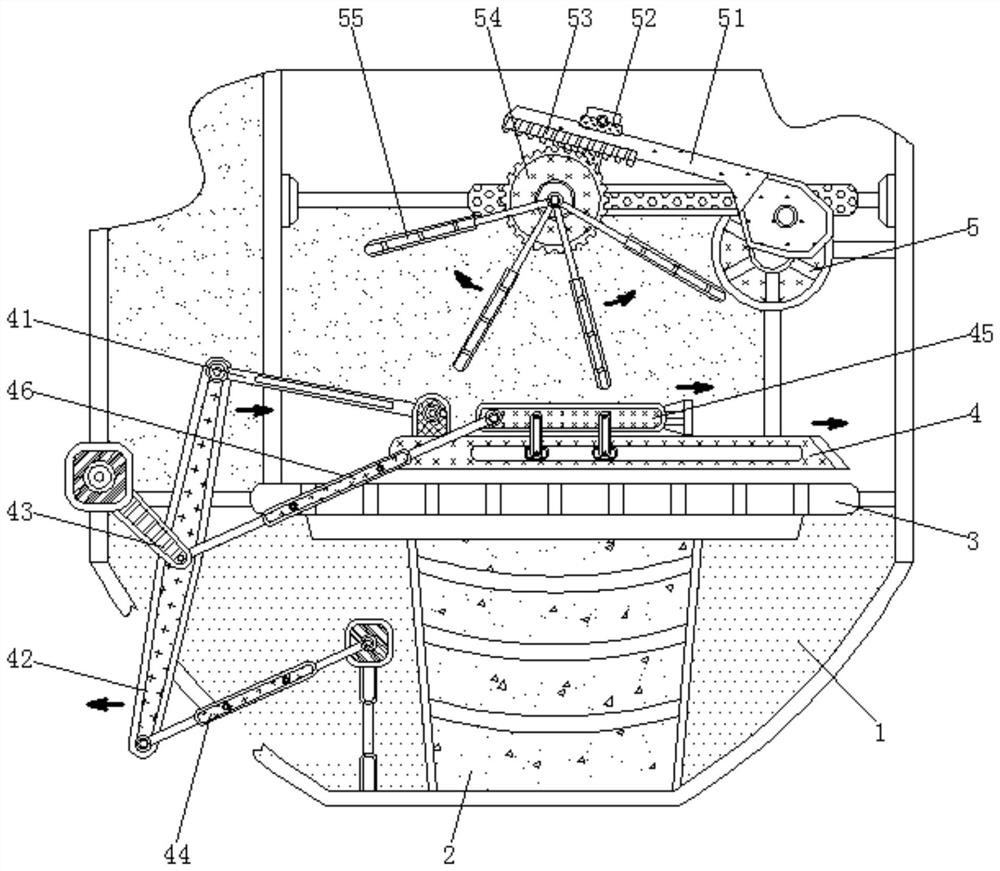

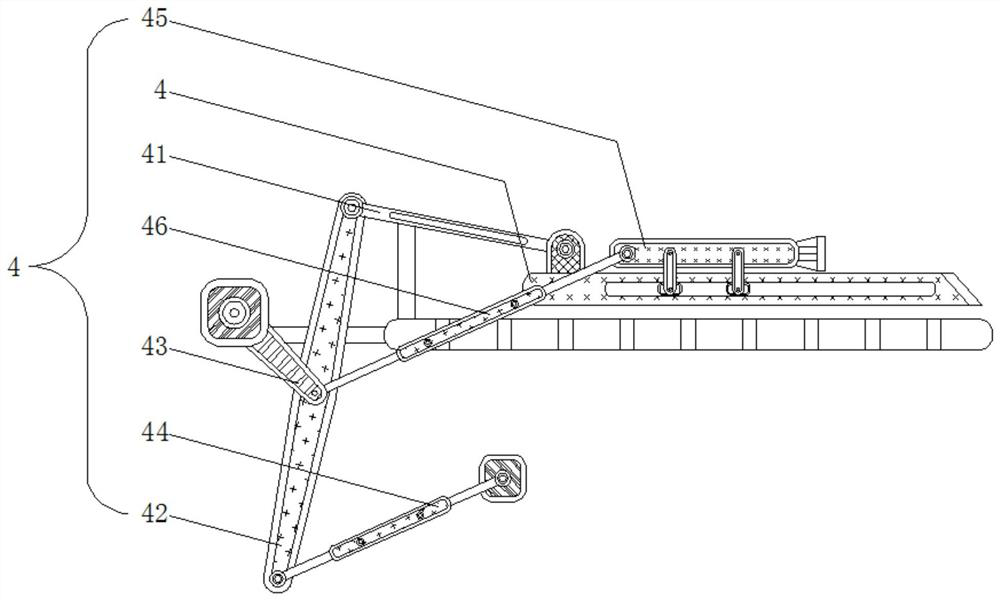

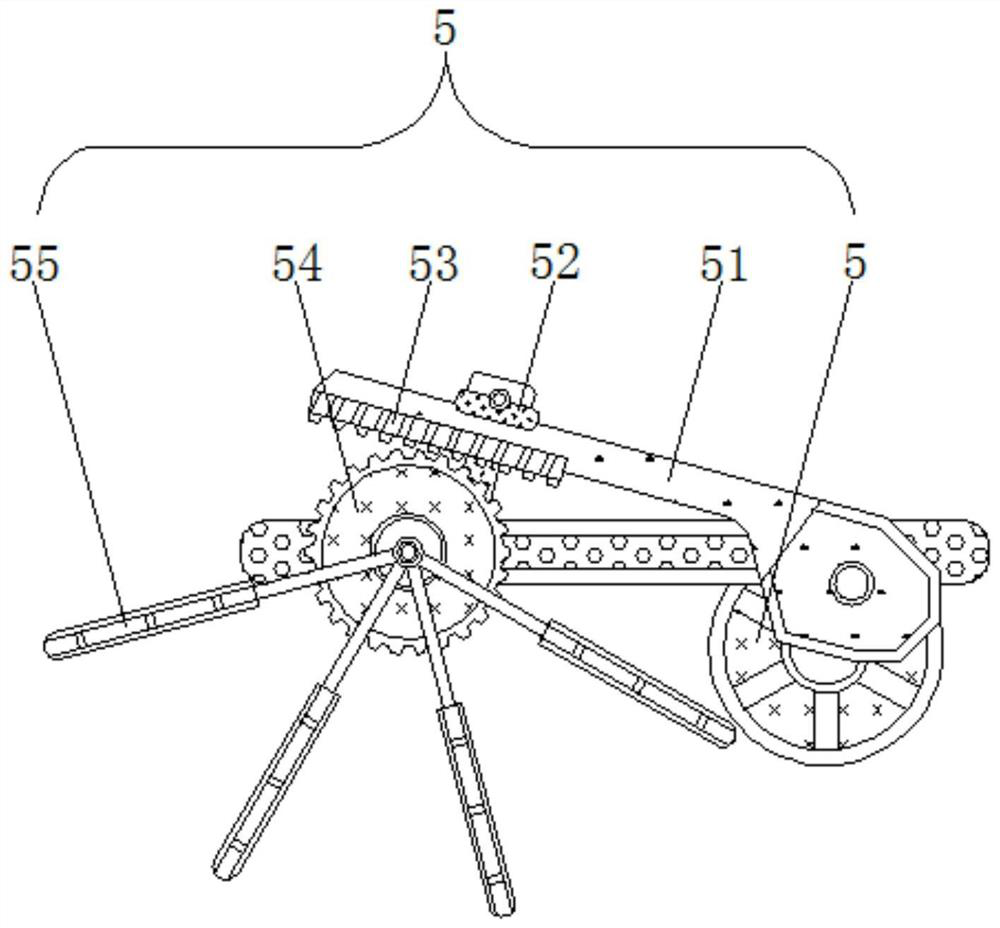

[0026] A chemical flash dryer device capable of intercepting agglomerated particles to prevent material accumulation, including a push plate mechanism 4, which is slidably connected to the surface of the material tray 3, and the end of the push plate mechanism 4 is provided with an inclined-plane push block, the push plate mechanism 4 and the inclined-plane push block are all close to the surface of the material tray 3, and one end of the first connecting rod 41 is rotatably connected to the end of the push plate mechanism 4 away from the inclined-plane push block, and the other end is rotatably connected to the swing rod 42 The surface of the push plate mechanism 4 is rotatably connected with a first connecting rod 41 , and the end of the first connecting rod 41 away from the push plate mechanism 4 is rotatably connected with a swing rod 42 .

[0027] The surface of the fork 42 is rotatably connected with a turn bar 43, one end of the turn bar 43 is rotatably connected to the ...

Embodiment 2

[0031] A chemical flash dryer device capable of intercepting agglomerated particles to prevent material accumulation, including a push plate mechanism 4, which is slidably connected to the surface of the material tray 3, and the end of the push plate mechanism 4 is provided with an inclined-plane push block, the push plate mechanism 4 and the inclined-plane push block are all close to the surface of the material tray 3, and one end of the first connecting rod 41 is rotatably connected to the end of the push plate mechanism 4 away from the inclined-plane push block, and the other end is rotatably connected to the swing rod 42 The surface of the push plate mechanism 4 is rotatably connected with a first connecting rod 41 , and the end of the first connecting rod 41 away from the push plate mechanism 4 is rotatably connected with a swing rod 42 .

[0032] The surface of the fork 42 is rotatably connected with a turn bar 43, one end of the turn bar 43 is rotatably connected to the ...

Embodiment 3

[0036] A chemical flash dryer device capable of intercepting agglomerated particles to prevent material accumulation, including a push plate mechanism 4, which is slidably connected to the surface of the material tray 3, and the end of the push plate mechanism 4 is provided with an inclined-plane push block, the push plate mechanism 4 and the inclined-plane push block are all close to the surface of the material tray 3, and one end of the first connecting rod 41 is rotatably connected to the end of the push plate mechanism 4 away from the inclined-plane push block, and the other end is rotatably connected to the swing rod 42 The surface of the push plate mechanism 4 is rotatably connected with a first connecting rod 41 , and the end of the first connecting rod 41 away from the push plate mechanism 4 is rotatably connected with a swing rod 42 .

[0037] The surface of the fork 42 is rotatably connected with a turn bar 43, one end of the turn bar 43 is rotatably connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com