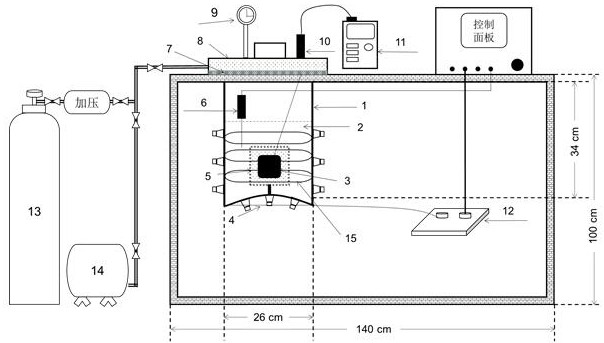

Low-frequency ultrasonic-assisted liquefied CO2 quick-freezing device and method based on ice crystal regulation and control

An ultrasonic-assisted, quick-freezing device technology, applied in the field of food processing, can solve the problems of difficulty in feeding and taking out materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Example 1: Cantaloupe

[0069] (1) Raw material pretreatment:

[0070] a. Raw material screening and cleaning: select Hami melons with uniform size, moderate maturity and no mechanical damage, and then clean them;

[0071] b. Cutting: Cut the cleaned Hami melon along the central equator line, and then use a self-made puncher to punch out cylindrical Hami melon samples with a diameter of 2.5 cm and a height of 3 cm;

[0072] c. Enzyme inactivation: use 95°C hot water for blanching treatment, and the blanching time is controlled at 3 minutes;

[0073] d, water cooling: quickly place the blanched Hami melon sample in cold water to cool down to quickly reduce the temperature;

[0074] e. Drain: Drain the water on the surface of the Hami melon sample that has been inactivated and cooled;

[0075] f. Pre-cooling: air-cool the drained Hami melon material to -4°C.

[0076] (2) Liquefied CO 2 quick freezing

[0077] Place the pretreated cantaloupe samples in the freezer, a...

Embodiment 2

[0084] Example 2: grapes

[0085] (1) Raw material pretreatment:

[0086] a. Raw material screening and cleaning: select grapes with uniform size, moderate maturity and no mechanical damage, and then clean them;

[0087] b. Enzyme inactivation: use 95°C hot water for blanching treatment, and the blanching time is controlled at 2 minutes;

[0088] c. Water cooling: quickly cool the blanched grape samples in cold water to quickly lower the temperature;

[0089] d. Drain: Drain the surface moisture of the grape samples that have been inactivated and cooled;

[0090] e. Pre-cooling: air-cool the drained grape material to -4°C.

[0091] (2) Liquefied CO 2 quick freezing

[0092] Place the pretreated grape sample in the freezer, and insert a precision thermocouple into one of the sample centers to measure the temperature change in the center of the material; close the valve to keep the freezer sealed; open the vacuum valve to draw out the air in the freezer, close the Vacuum v...

Embodiment 3

[0099] Example 3: Carrots

[0100] (1) Raw material pretreatment:

[0101] a. Raw material screening and cleaning: select carrots with uniform size, moderate maturity and no mechanical damage, and then clean them;

[0102] b. Slicing: Punch the cleaned carrots into cylinders with a diameter of 2.5 cm using a self-made puncher, and then cut them into samples with a thickness of 1 cm;

[0103] c. Enzyme inactivation: use 95°C hot water for blanching treatment, and the blanching time is controlled at 1 min;

[0104] d. Water cooling: quickly place the blanched carrot samples in cold water to cool down quickly to lower the temperature;

[0105] e, draining: drain the moisture on the surface of the carrot sample after the enzyme is eliminated and cooled;

[0106] f. Pre-cooling: air-cool the drained carrot material to -4°C.

[0107] (2) Liquefied CO 2 quick freezing

[0108] Place the pretreated carrot sample in the freezer, and insert a precision thermocouple into the center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com