Guiding hole wall protecting slurry

A pilot hole and mud technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of reducing the drilling speed, weakening the impact function of the drill bit, and poor wall protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

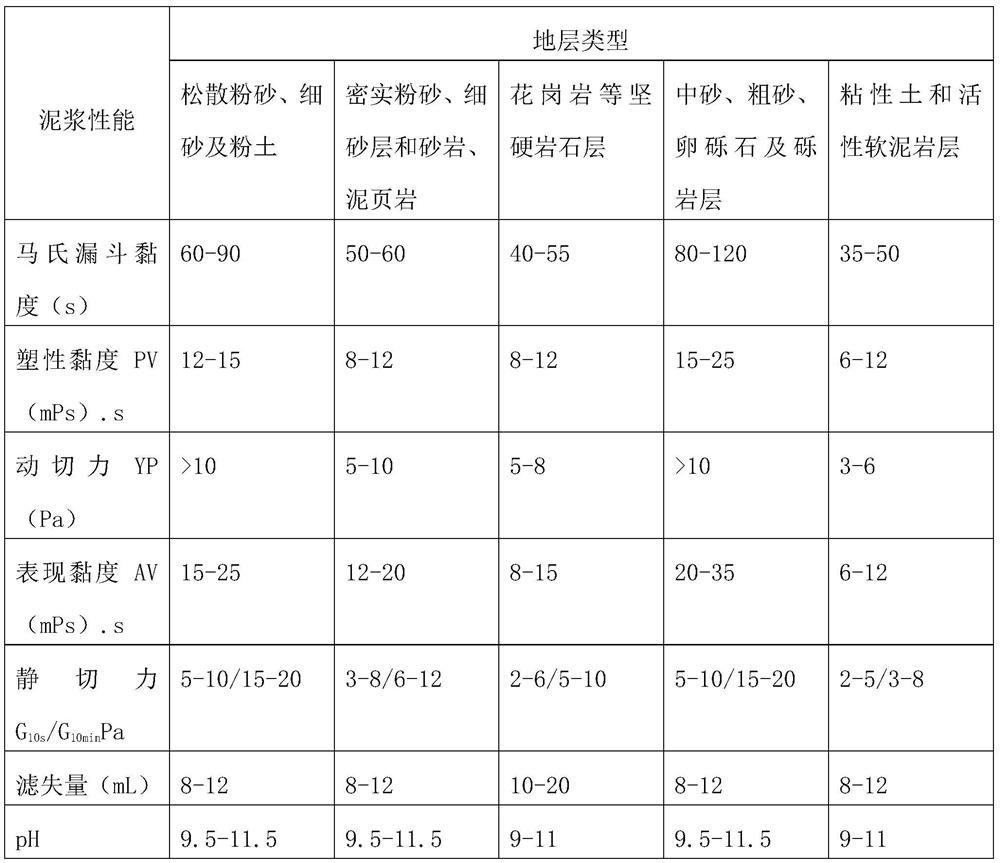

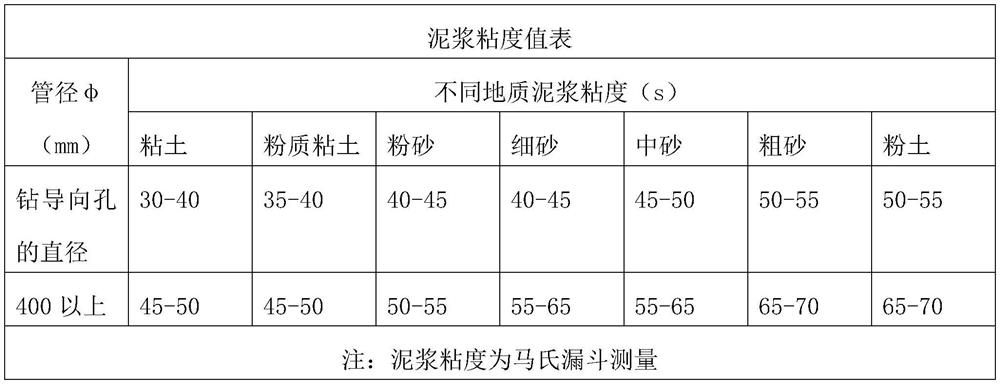

[0034] In the actual directional drilling crossing construction process, it involves the technological process of drilling pilot holes, reaming, and pulling back pipes.

[0035] In the present embodiment, the guide hole wall protection mud, the mud is calculated according to parts by weight, and its composition ratio is as follows: comprise 70-75 parts of water, 20-28 parts of bentonite, and a content of 2% of bentonite weight additive, according to the directional drilling Prepare mud in each stage of pilot hole, pre-reaming and pull-back:

[0036] The mud in the pilot hole drilling stage uses the following raw materials in proportions by weight: 7-8 parts of bentonite, 0.2-0.4 parts of additives, 0.1-0.3 parts of fluid loss control agent;

[0037] The mud in the pre-expansion stage uses the following ratios of raw materials: 7-8 parts of bentonite, 0.3-0.5 parts of viscosity enhancing agent, and 0.1-0.4 parts of fluid loss control agent;

[0038] The mud in the pull-back st...

Embodiment 2

[0054] The difference between the present embodiment and the first embodiment is that the guide hole wall protection mud is calculated in parts by weight, and its composition ratio is as follows: including 75 parts of water, 28 parts of bentonite, and an additive with a content of 2% by weight of bentonite. Prepare mud at each stage of pilot hole, pre-expanding and pullback in directional drilling:

[0055] The mud in the pilot hole drilling stage uses the following raw materials in proportions by weight: 8 parts of bentonite, 0.4 parts of additives, and 0.3 parts of fluid loss control agent;

[0056]The mud in the pre-expansion stage uses the following proportions of raw materials: 8 parts of bentonite, 0.5 part of viscosity increasing agent, and 0.4 part of fluid loss reducer;

[0057] The mud in the pull-back stage uses the following proportions of raw materials: 8 parts of bentonite, 0.5 parts of viscosity increasing agent, 0.4 parts of fluid loss control agent, and 3 part...

Embodiment 3

[0059] The difference with Embodiment 1 is: the mud for the wall protection of the pilot hole, and the mud is calculated according to parts by weight. Prepare mud in each stage of pilot hole, pre-reaming and pull-back:

[0060] The mud in the pilot hole drilling stage uses the following raw materials in proportions by weight: 7.5 parts of bentonite, 0.3 parts of additives, and 0.2 parts of fluid loss control agent;

[0061] The mud in the pre-expansion stage uses the following proportions of raw materials: 7.5 parts of bentonite, 0.4 parts of viscosity enhancing agent, and 0.3 parts of fluid loss reducer;

[0062] The mud in the pull-back stage uses the following proportions of raw materials: 7.5 parts of bentonite, 0.4 parts of viscosity enhancer, 0.3 parts of fluid loss control agent, and 2.5 parts of lubricant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com