Ceramic material and repair material for improving surface adhesion of dental zirconia, and preparation method and bonding method of ceramic material and repair material

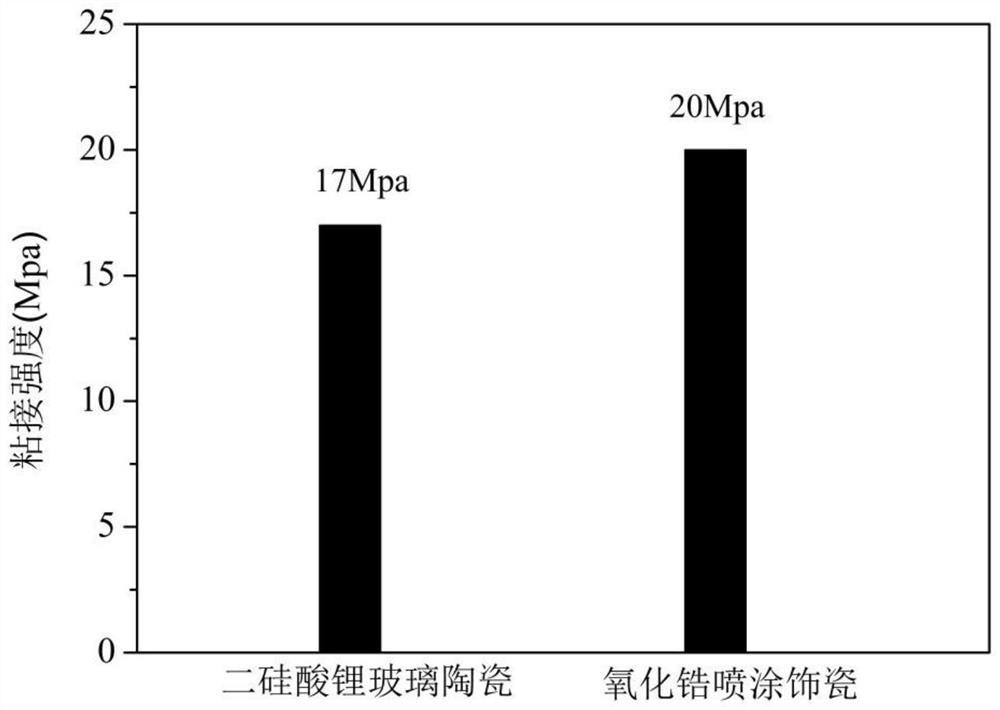

A technology of ceramic materials and restoration materials, applied in dental preparations, dentistry, dental prostheses, etc., can solve problems such as difficult bonding of zirconia, achieve the goal of improving interface adhesion, increasing bonding strength, and reducing high-temperature melting temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] This embodiment provides a method for preparing a restoration material for improving the bonding performance of the inner surface of dental zirconia, the preparation method comprising the following steps:

[0059] (1) Mix the components in the ceramic material uniformly in proportion (see Table 1 for the mass ratio of the components), place the mixed raw materials in a crucible, and melt at 1350°C for 10 hours, and then water Quenching to obtain glass slag;

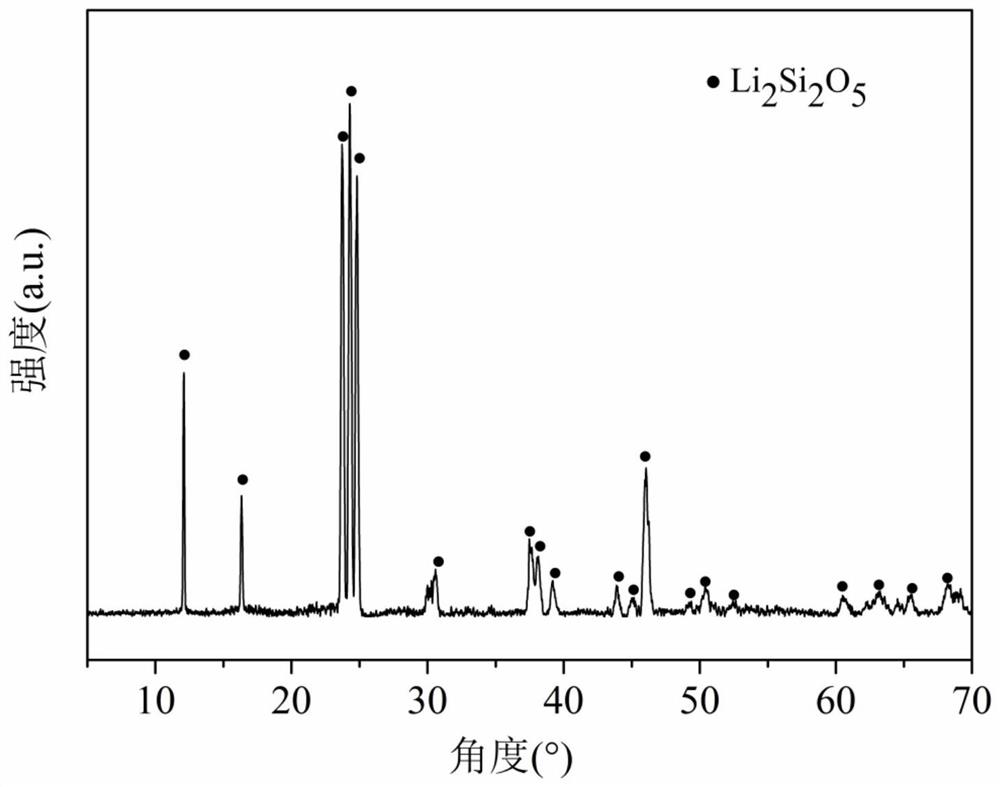

[0060] (2) Heat the glass slag material obtained in step (1) at 480°C for 180 minutes to obtain a glass slag material with nucleation, and continue to raise the temperature to 620°C for 100 minutes to obtain a lithium metasilicate crystal that is extremely easy to process and grind ;

[0061](3) The lithium metasilicate crystal obtained in step (2) is ground to prepare a glass powder with a particle size of 2 μm; then add the coloring agent TiO 2 , add water and mix to prepare powder slurry;

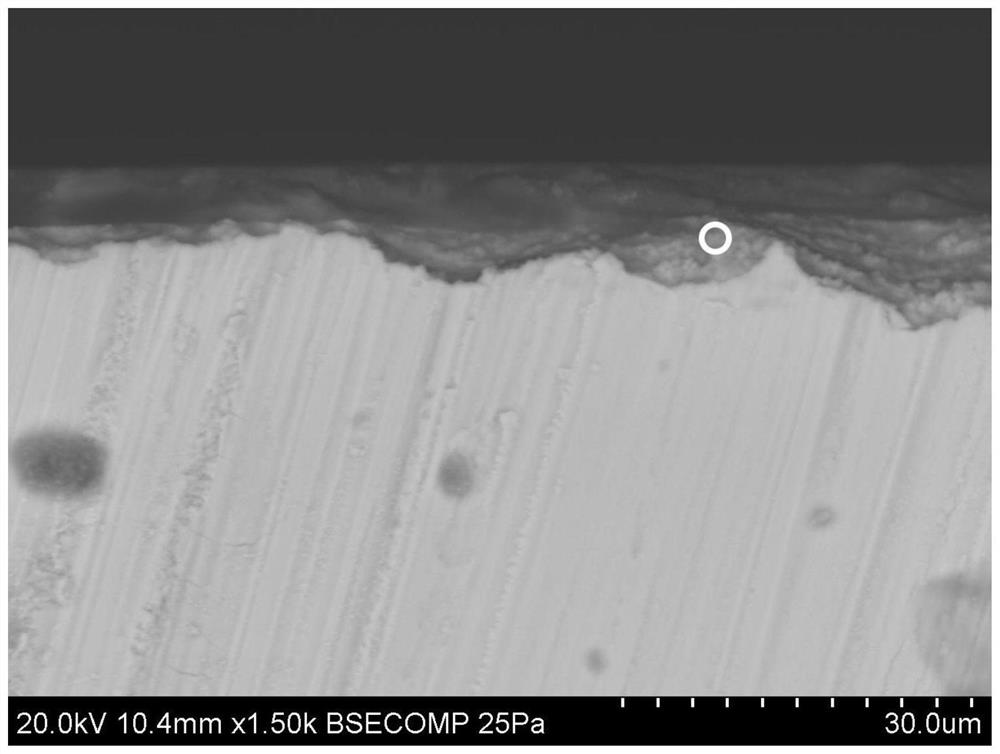

[0062] (4) Spray t...

Embodiment 2

[0070] This embodiment provides a method for preparing a restoration material for improving the bonding performance of the inner surface of dental zirconia, the preparation method comprising the following steps:

[0071] (1) Mix the components in the ceramic material uniformly in proportion (see Table 1 for the mass ratio of the components), place the mixed raw materials in a crucible, and melt at 1320°C for 12 hours, and then water Quenching to obtain glass slag;

[0072] (2) Heat the glass slag material obtained in step (1) at 500°C for 160 minutes to obtain a glass slag material with nucleation, and continue to raise the temperature to 640°C for 140 minutes to obtain a lithium metasilicate crystal that is extremely easy to process and grind ;

[0073] (3) Grinding the lithium metasilicate crystal obtained in step (2) to prepare a glass powder with a particle size of 5 μm; then adding the pigment zirconium spectrum yellow, adding alcohol and mixing to prepare a powder slurr...

Embodiment 3

[0078] This embodiment provides a method for preparing a restoration material for improving the bonding performance of the inner surface of dental zirconia, the preparation method comprising the following steps:

[0079] (1) Mix the components in the ceramic material uniformly in proportion (see Table 1 for the mass ratio of the components), place the mixed raw materials in a crucible, and melt at 1280°C for 12 hours, and then water Quenching to obtain glass slag;

[0080] (2) Heat the glass slag material obtained in step (1) at 520°C for 120 minutes to obtain a glass slag material with nucleation, and continue to raise the temperature to 670°C for 200 minutes to obtain lithium metasilicate crystals that are extremely easy to process and grind ;

[0081] (3) Grinding the lithium metasilicate crystal obtained in step (2) to prepare a glass powder with a particle size of 4 μm; then adding the pigment zirconium spectrum yellow, adding alcohol and mixing to prepare a powder slurr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com