Outward-turning bending die for strip-shaped piece

A strip and mold technology, applied in the field of eversion bending molds, can solve the problems of poor stripping of long workpieces, and achieve the effects of avoiding material jamming, large elastic potential energy, and avoiding mutual jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

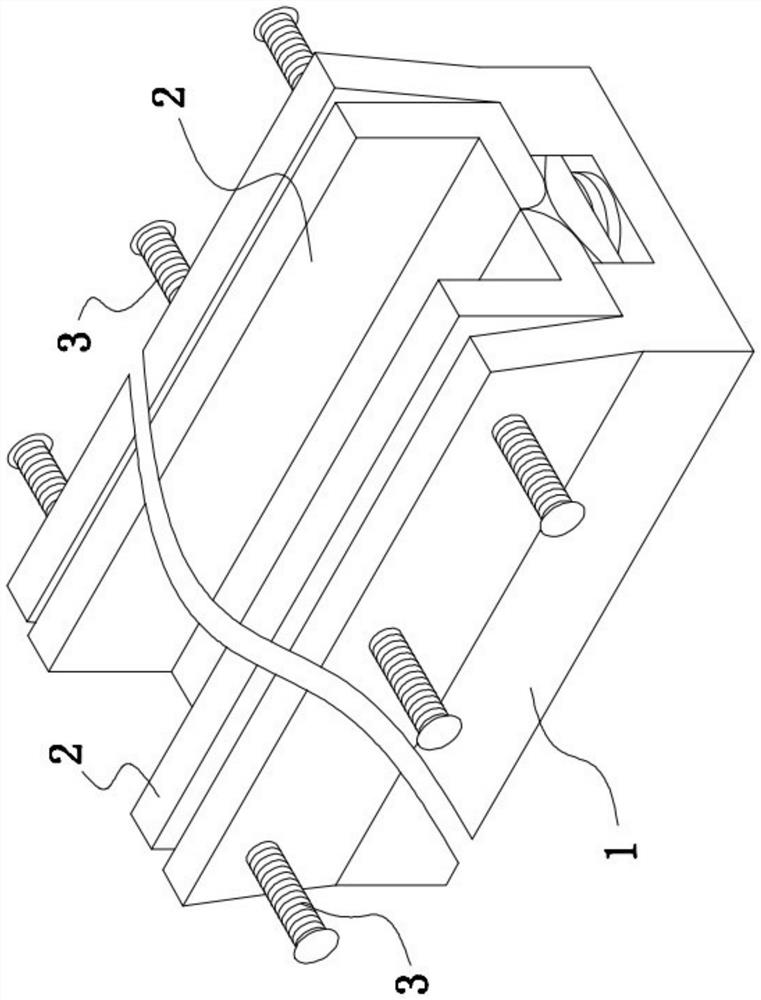

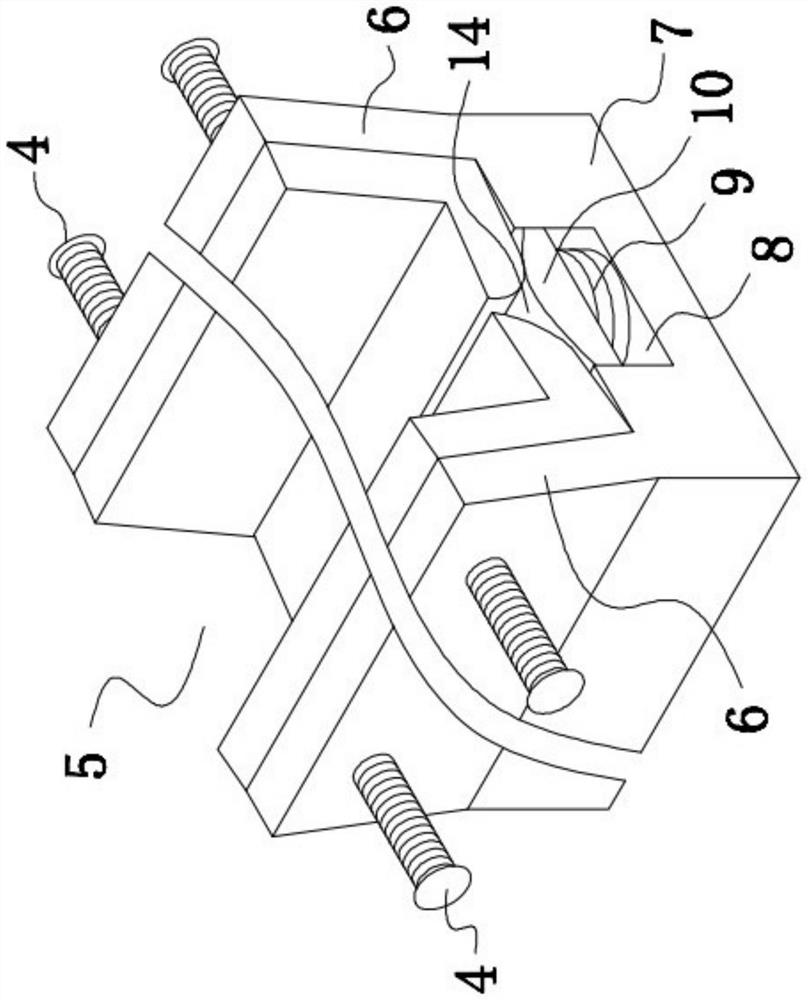

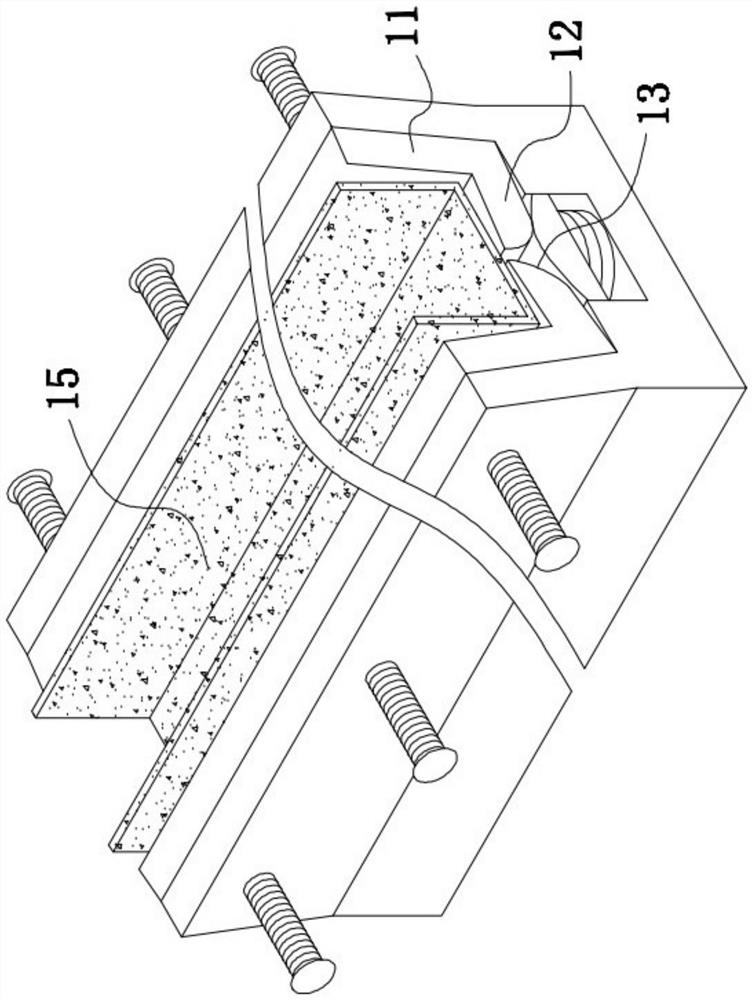

[0028] In order to achieve the purpose of the present invention, a kind of valgus bending mold that is used for bar-shaped part comprises: module, comprises outer module 1, inner module 2, and the top of outer module 1 itself comprises a pair of mirror-image arranged inclined plates 6, The distance between the respective tops of the two inclined plates 6 is greater than the distance between the respective bottoms; the two inner modules 2 are mirrored and arranged between the two inclined plates 6, and the cross-sectional track of each inner module 2 is L-shaped; The elastic member includes a horizontal compression spring 3 and a vertical compression spring 9; the inner module 2 is fixed with a guide post passing through the inclined plate 6, and the guide post is covered with a horizontal compression spring 3; the vertical compression spring 9 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com