Single-cylinder reset stripping device of press machine for sheet stamping

A thin plate stamping and stripping device technology, applied in the field of presses, can solve the problems of rapid oil temperature rise, increased heat dissipation system load, energy loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

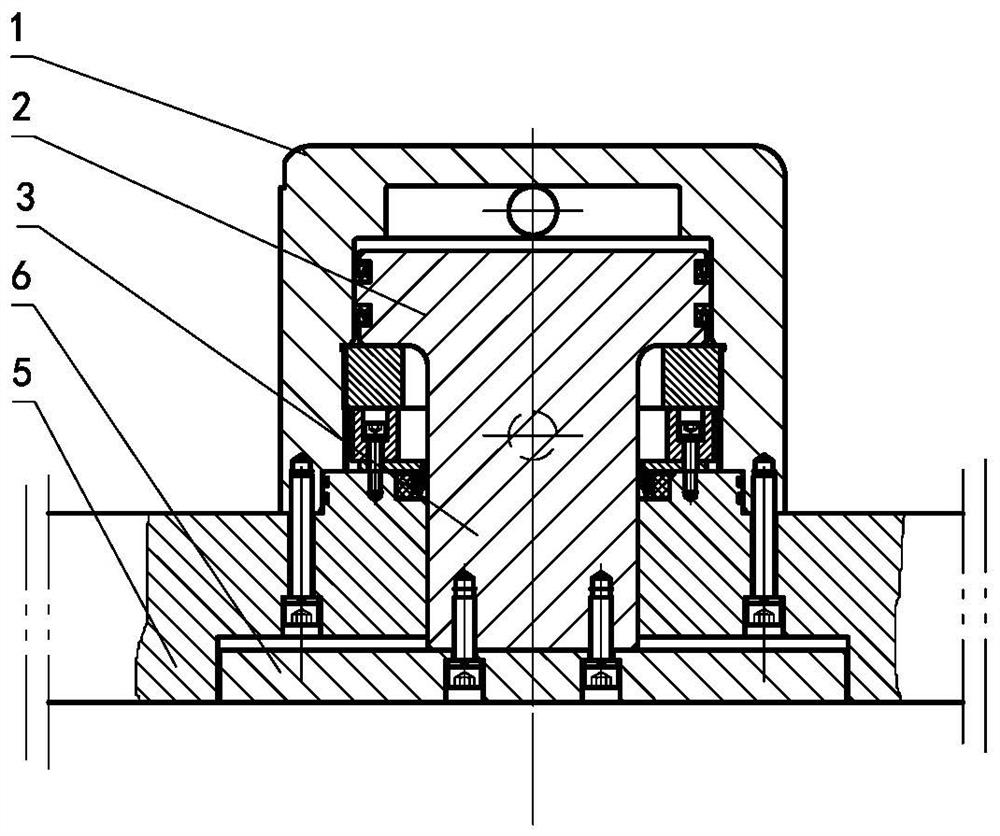

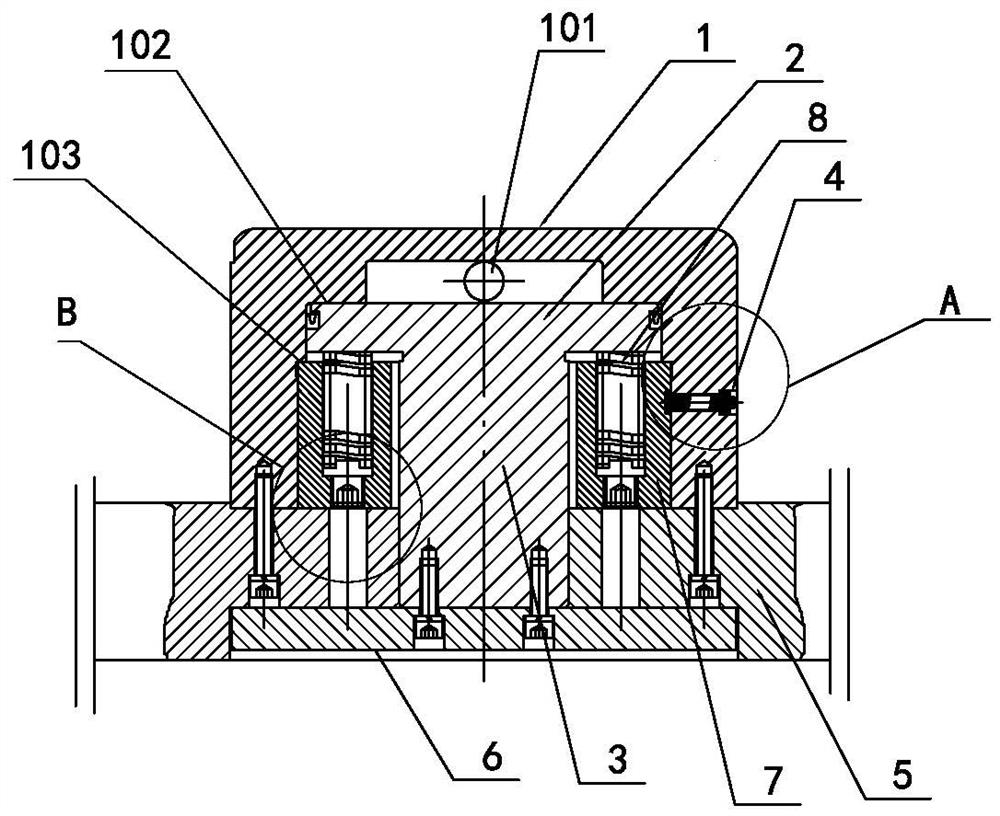

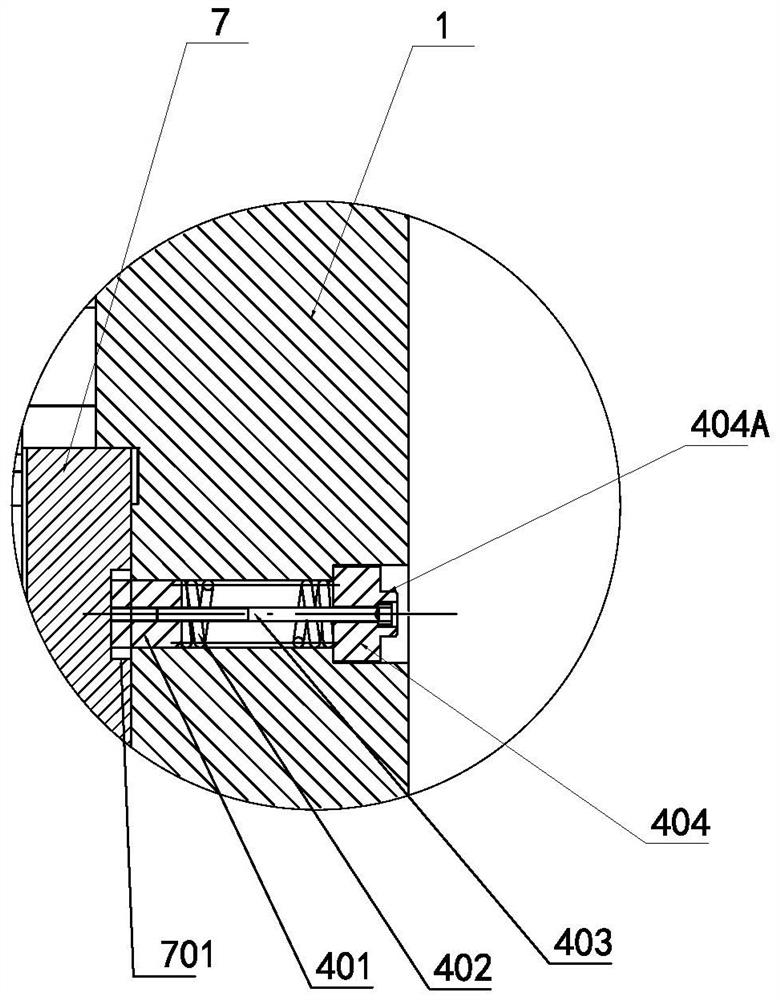

[0020] Such as figure 2 — Figure 4 Shown is the press single-cylinder reset stripping device for thin plate stamping of the present invention, including a cylinder body 1, a piston 2 and a cylinder seat 5, the lower side of the piston 2 is integrally connected to the piston rod 3, and the cylinder body 2 is provided with a limiter. The inner step 102 at the upper limit position of the piston 2, the upper side of the inner step 102 is provided with an oil inlet and outlet 101, a spacer 7 is provided between the cylinder body 1 and the piston rod 3, and a number of reset chambers are provided in the circumferential direction of the spacer 7. A return spring 8 is provided in the cavity, and the lower end of the spacer 7 abuts against the cylinder base 5, and the upper end of the spacer 7 corresponds to an inner step 2 103 in the cylinder body 1, and the upper end of the spacer 7 abuts against the inner step 103, and the spacer 7 A reset space is provided between the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com