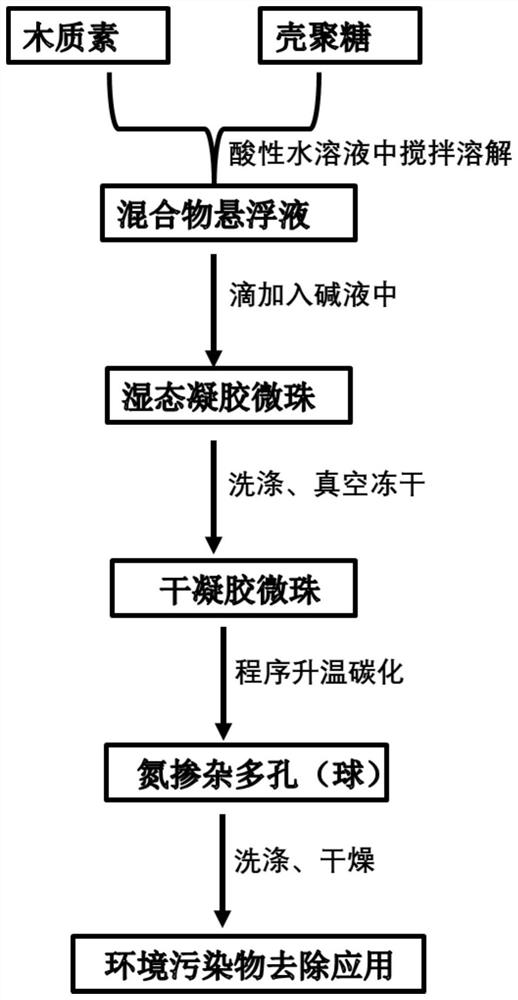

Millimeter-scale nitrogen-doped porous carbon sphere as well as preparation and application thereof

A nitrogen-doped porous carbon, millimeter-scale technology, applied in the preparation/purification of carbon, other chemical processes, chemical instruments and methods, etc., can solve the problems affecting the recycling and regeneration of carbon materials, the limitation of use scenarios, and the lack of regulation of performance. Achieve the effect of improving yield and mechanical strength, broad market prospects, and low requirements for equipment conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

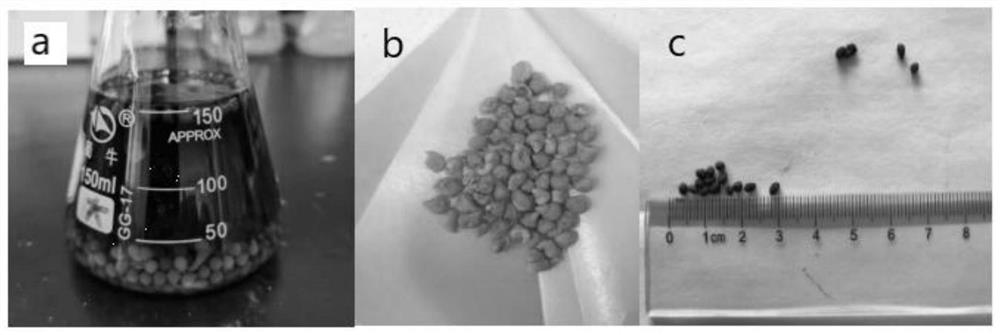

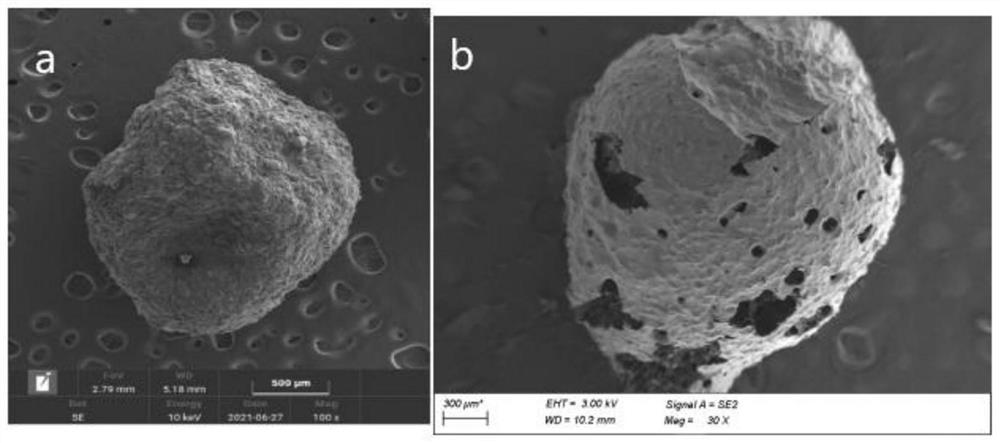

[0085](1) Weigh 2.0g sodium lignosulfonate and 2.0g chitosan in a beaker, add 30mL distilled water to disperse, then add 15mL of 2mol / L hydrochloric acid solution, stir it in a water bath at room temperature for 1h It is fully dissolved to obtain suspension A, and then under the condition of 20r / min magnetic stirring, at a rate of 2 drops / s, the height of the droplet is 2cm from the liquid surface, and 100mL of hydrogen with a mass concentration of 8% is added dropwise Carry out gel self-assembly in the potassium oxide solution, after the dropwise addition, stand and solidify for 10 hours, filter and separate to obtain wet gel microbeads;

[0086] (2) Mix the wet gel beads with a certain amount of water, and then filter, which can be repeated several times until the pH of the filtrate is 7, and the solid is then subjected to vacuum freeze-drying for 20 hours to obtain the precursor xerogel beads, which are dried and stored for later use .

[0087] (3) Weigh 2.0 g of xerogel b...

Embodiment 2

[0090] (1) Weigh 2.0g sodium lignosulfonate and 2.0g chitosan in a beaker, add 30mL distilled water to disperse, then add 20mL of 3mol / L hydrochloric acid solution, stir it in a water bath at room temperature for 1h It is fully dissolved to obtain a suspension A, and then under the condition of 20r / min magnetic stirring, at a rate of 2 drops / s, the height of the droplet is 1cm from the liquid surface, and 100mL of hydrogen with a mass concentration of 9% is added dropwise Carry out gel self-assembly in the potassium oxide solution, after the dropwise addition, stand and solidify for 10 hours, filter and separate to obtain wet gel microbeads;

[0091] (2) Mix the wet gel beads with water, and then filter, which can be repeated several times until the pH of the filtrate is 8, and the solid is then subjected to vacuum freeze-drying for 20 hours to obtain the precursor xerogel beads, which are dried and stored for later use.

[0092] (3) Weigh 2.0 g of xerogel balls and place them...

Embodiment 3

[0094] (1) Weigh 1.0g sodium lignosulfonate and 3.0g chitosan in a beaker, add 50mL distilled water to disperse, then add 20mL of 3mol / L hydrochloric acid solution, stir it in a water bath at room temperature for 1h It is fully dissolved to obtain a suspension A, and then under the condition of 20r / min magnetic stirring, at a rate of 2 drops / s, the height of the droplet is 3cm from the liquid surface, and 100mL of hydrogen with a mass concentration of 9% is added dropwise Carry out gel self-assembly in the potassium oxide solution, after the dropwise addition, stand and solidify for 10 hours, filter and separate to obtain wet gel microbeads;

[0095] (2) The wet gel beads were mixed with water, and then filtered until the pH of the filtrate was 7, and the solid was vacuum freeze-dried for 20 hours to obtain the precursor xerogel beads, which were dried and stored for later use.

[0096] (3) Weigh 2.0 g of xerogel balls and place them in a horizontal tubular reactor under the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com